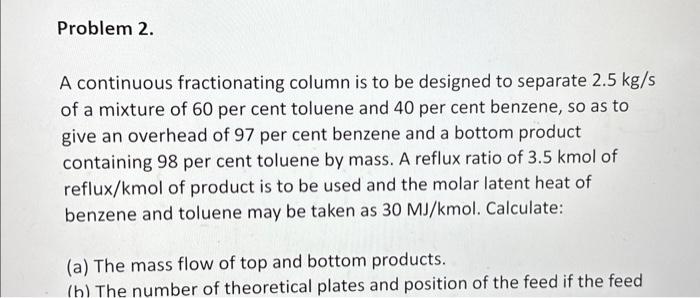

Question: A continuous fractionating column is to be designed to separate 2.5kg/s of a mixture of 60 per cent toluene and 40 per cent benzene, so

A continuous fractionating column is to be designed to separate 2.5kg/s of a mixture of 60 per cent toluene and 40 per cent benzene, so as to give an overhead of 97 per cent benzene and a bottom product containing 98 per cent toluene by mass. A reflux ratio of 3.5kmol of reflux/kmol of product is to be used and the molar latent heat of benzene and toluene may be taken as 30MJ/kmol. Calculate: (a) The mass flow of top and bottom products. (h) The number of theoretical plates and position of the feed if the feed (b) The number of theoretical plates and position of the feed if the feed is liquid at 295K, of specific heat capacity 1.84kJ/kgK. (c) How much steam at 240kN/m2 is required in the still. (d) What will be the required diameter of the column if it operates at atmospheric pressure and a vapour velocity of 1m/s. (e) If the vapour velocity is to be 0.75m/s, based on free area of column, determine the necessary diameter of the column. (f) The minimum possible reflux ratio, and the minimum number of plates for a feed entering at its boiling-point

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts