Question: A double-effect evaporator with reverse feed is used to concentrate 4536 kg/hr of a 10 wt% of sugar solution to 50%. The feed enters the

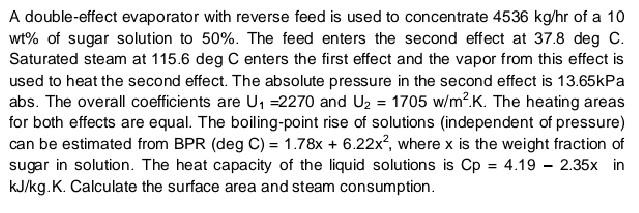

A double-effect evaporator with reverse feed is used to concentrate 4536 kg/hr of a 10 wt% of sugar solution to 50%. The feed enters the second effect at 37.8 deg C. Saturated steam at 115.6 deg C enters the first effect and the vapor from this effect is used to heat the second effect. The absolute pressure in the second effect is 13.65kPa abs. The overall coefficients are U1 =2270 and U2 = 1705 w/m2 .K. The heating areas for both effects are equal. The boiling-point rise of solutions (independent of pressure) can be estimated from BPR (deg C) = 1.78x + 6.22x2 , where x is the weight fraction of sugar in solution. The heat capacity of the liquid solutions is Cp = 4.19 2.35x in kJ/kg.K. Calculate the surface area and steam consumption.

A double-effect evaporator with reverse feed is used to concentrate 4536 kg/hr of a 10 wt% of sugar solution to 50%. The feed enters the second effect at 37.8 deg C. Saturated steam at 115.6 deg C enters the first effect and the vapor from this effect is used to heat the second effect. The absolute pressure in the second effect is 13.65kPa abs. The overall coefficients are U, =2270 and U2 = 1705 w/m2K. The heating areas for both effects are equal. The boiling-point rise of solutions (independent of pressure) can be estimated from BPR (deg C) = 1.78x + 6.22x, where x is the weight fraction of sugar in solution. The heat capacity of the liquid solutions is Cp = 4.19 - 2.35x in kJ/kg.K. Calculate the surface area and steam consumption

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts