Question: A firm uses a simple six-step process to prepare its products for shipment. Because of the recent increase in demand, the company is setting up

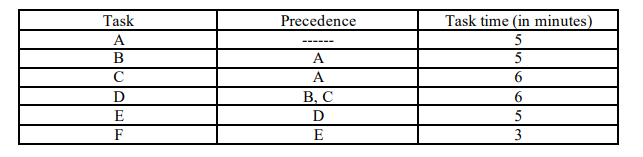

A firm uses a simple six-step process to prepare its products for shipment. Because of the recent increase in demand, the company is setting up an assembly line to do the work. The firm would like to organize the work as efficiently as possible. A list of tasks, task times, and precedence requirements are given in the following table.

What are the minimum and maximum cycle times? What hourly range of theoretical output is possible for this assembly line?

If the company needs a new product off the assembly line every 10 minutes (i.e., cycle time), what is the theoretical minimum number of employees needed? Balance the assembly line (i.e., assign tasks to workstations). How many employees should be hired (i.e., the actual number of employees)? Calculate the efficiency of the assembly line. How many packages can be assembled in an eight-hour shift using the balanced assembly line?

Precedence Task A B D E F A A B, C D E Task time (in minutes) 5 5 6 6 5 3Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts