Question: A foundry has received an order for 2 0 custom - designed castings. The casting process costs $ 7 0 0 per unit scheduled. If

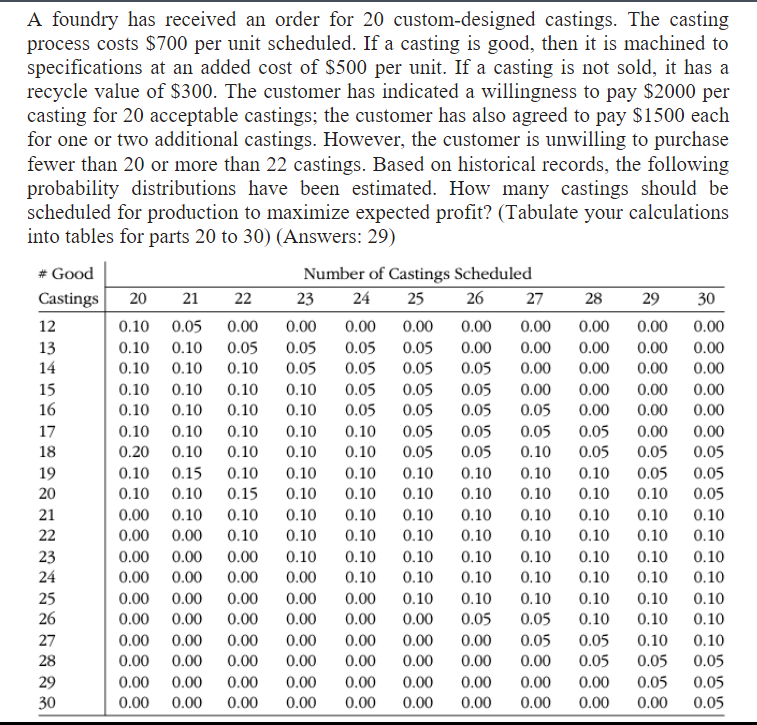

A foundry has received an order for customdesigned castings. The casting

process costs $ per unit scheduled. If a casting is good, then it is machined to

specifications at an added cost of $ per unit. If a casting is not sold, it has a

recycle value of $ The customer has indicated a willingness to pay $ per

casting for acceptable castings; the customer has also agreed to pay $ each

for one or two additional castings. However, the customer is unwilling to purchase

fewer than or more than castings. Based on historical records, the following

probability distributions have been estimated. How many castings should be

scheduled for production to maximize expected profit? Tabulate your calculations

into tables for parts to Answers:

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock