Question: A glass store is developing a production plan for producing glass vases. The demand forecast is 200 units for January; 300 units for February; 250

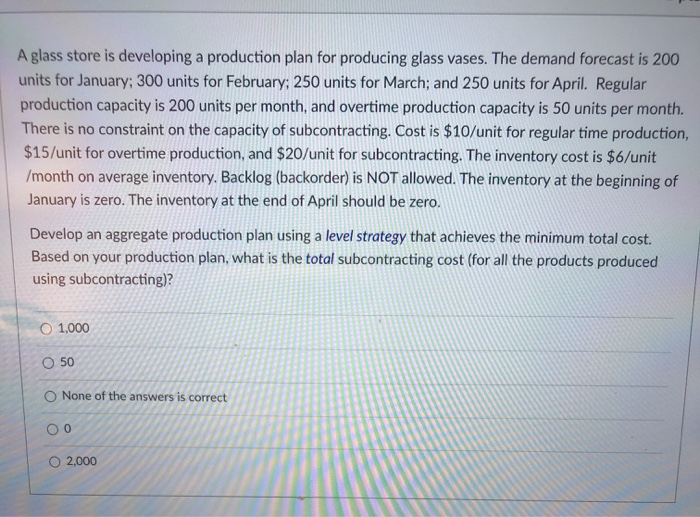

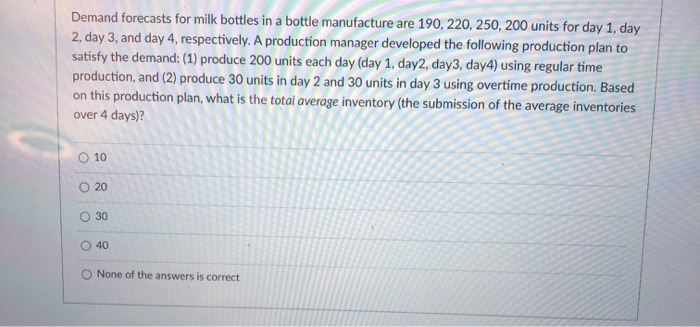

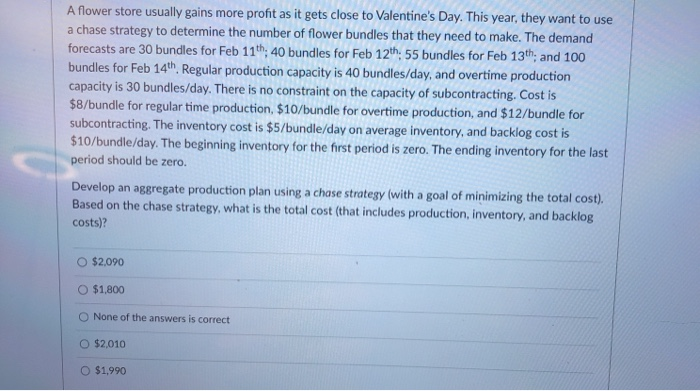

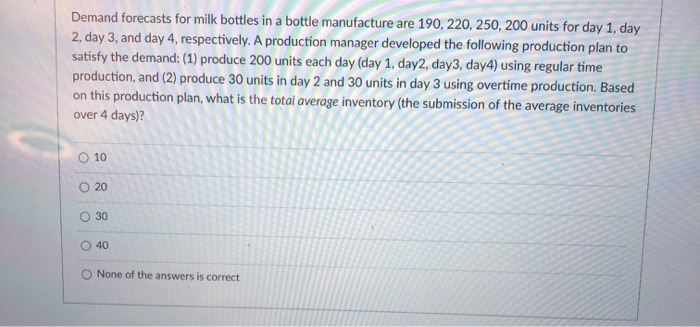

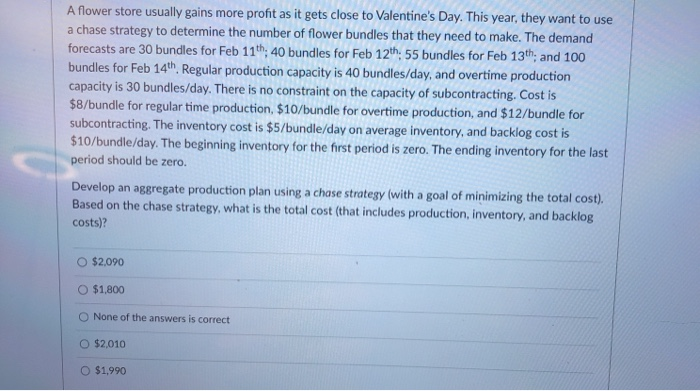

A glass store is developing a production plan for producing glass vases. The demand forecast is 200 units for January; 300 units for February; 250 units for March; and 250 units for April. Regular production capacity is 200 units per month, and overtime production capacity is 50 units per month. There is no constraint on the capacity of subcontracting. Cost is $10/unit for regular time production, $15/unit for overtime production, and $20/unit for subcontracting. The inventory cost is $6/unit /month on average inventory. Backlog (backorder) is NOT allowed. The inventory at the beginning of January is zero. The inventory at the end of April should be zero. Develop an aggregate production plan using a level strategy that achieves the minimum total cost. Based on your production plan, what is the total subcontracting cost (for all the products produced using subcontracting)? 1,000 O 50 None of the answers is correct O 2,000 Demand forecasts for milk bottles in a bottle manufacture are 190, 220, 250, 200 units for day 1, day 2, day 3, and day 4, respectively. A production manager developed the following production plan to satisfy the demand: (1) produce 200 units each day (day 1, day, day3, day4) using regular time production, and (2) produce 30 units in day 2 and 30 units in day 3 using overtime production. Based on this production plan, what is the total average inventory (the submission of the average inventories over 4 days)? 10 0 20 30 40 None of the answers is correct A flower store usually gains more profit as it gets close to Valentine's Day. This year, they want to use a chase strategy to determine the number of flower bundles that they need to make. The demand forecasts are 30 bundles for Feb 11th, 40 bundles for Feb 12th, 55 bundles for Feb 13th, and 100 bundles for Feb 14th. Regular production capacity is 40 bundles/day, and overtime production capacity is 30 bundles/day. There is no constraint on the capacity of subcontracting. Cost is $8/bundle for regular time production, $10/bundle for overtime production, and $12/bundle for subcontracting. The inventory cost is $5/bundle/day on average inventory, and backlog cost is $10/bundle/day. The beginning inventory for the first period is zero. The ending inventory for the last period should be zero. Develop an aggregate production plan using a chase strategy (with a goal of minimizing the total cost). Based on the chase strategy, what is the total cost (that includes production, inventory, and backlog costs)? $2,090 $1,800 None of the answers is correct O $2,010 O $1,990