Question: A. How long does it take a unit to go from the beginning to the end of the line? B. In a four hour period,

A. How long does it take a unit to go from the beginning to the end of the line? B. In a four hour period, how many units would be produced on this line? (Assume the line begins and ends with the period full of units) C. What is the efficiency of the line? D. If the layout for this line consisted of three workstations, how would you expect the cycle time, efficiency, and production rate to be affected? (increase, decrease, remain the same, or it depends) E. What impact would the breakdown of a workstation have on production? F. What suggestions do you have for minimizing the effects of machine breakdowns in the future?

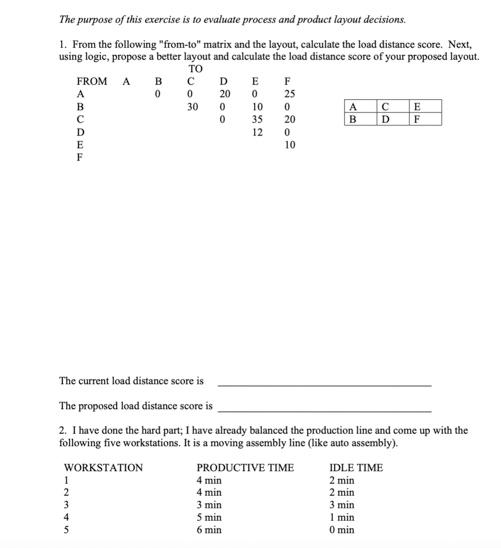

The purpose of this exercise is to evaluate process and product layout decisions. 1. From the following "from-to" matrix and the layout, calculate the load distance score. Next, using logic, propose a better layout and calculate the load distance score of your proposed layout TO FROM A B D F 0 0 25 B A 20 D 12 0 10 E 0 30 20 0 0 0 10 35 E F B D F The current load distance score is The proposed load distance score is 2. I have done the hard part; I have already balanced the production line and come up with the following five workstations, It is a moving assembly line (like auto assembly). WORKSTATION PRODUCTIVE TIME IDLE TIME 1 4 min 2 min 4 min 2 min 3 3 min 3 min S min 6 min 2 4 5 1 min O minStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts