Question: A job shop is analyzing the production process for one of its products in order to maximize the profitability. Based on customer demand the company

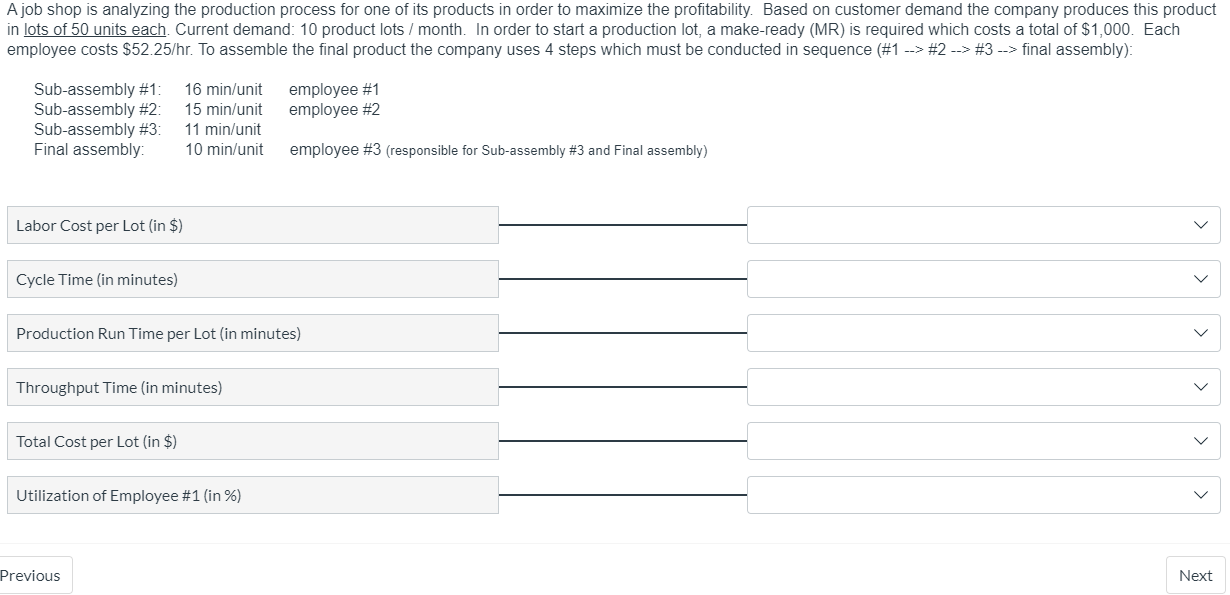

A job shop is analyzing the production process for one of its products in order to maximize the profitability. Based on customer demand the company produces this product in lots of 50 units each. Current demand: 10 product lots / month. In order to start a production lot, a make-ready (MR) is required which costs a total of $1,000. Each employee costs $52.25/hr. To assemble the final product the company uses 4 steps which must be conducted in sequence (#1 --> #2 --> #3 --> final assembly): Sub-assembly #1: Sub-assembly #2 Sub-assembly #3: Final assembly 16 min/unit 15 min/unit 11 min/unit 10 min/unit employee #1 employee #2 employee #3 (responsible for Sub-assembly #3 and Final assembly) Labor Cost per Lot (in $) Cycle Time (in minutes) Production Run Time per Lot (in minutes) Throughput Time (in minutes) Total Cost per Lot (in $) > Utilization of Employee #1 (in %) > Previous Next

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts