Question: Unit 2: Designing the Operations Designing the operations of an organization or your department - precedes operational management. For .ll _ . example, suppose a

![Upon successful completion ofthis unit, you will be able to: l] Recognize](https://dsd5zvtm8ll6.cloudfront.net/si.experts.images/questions/2024/11/672af80db3dd2_261672af80d8e076.jpg)

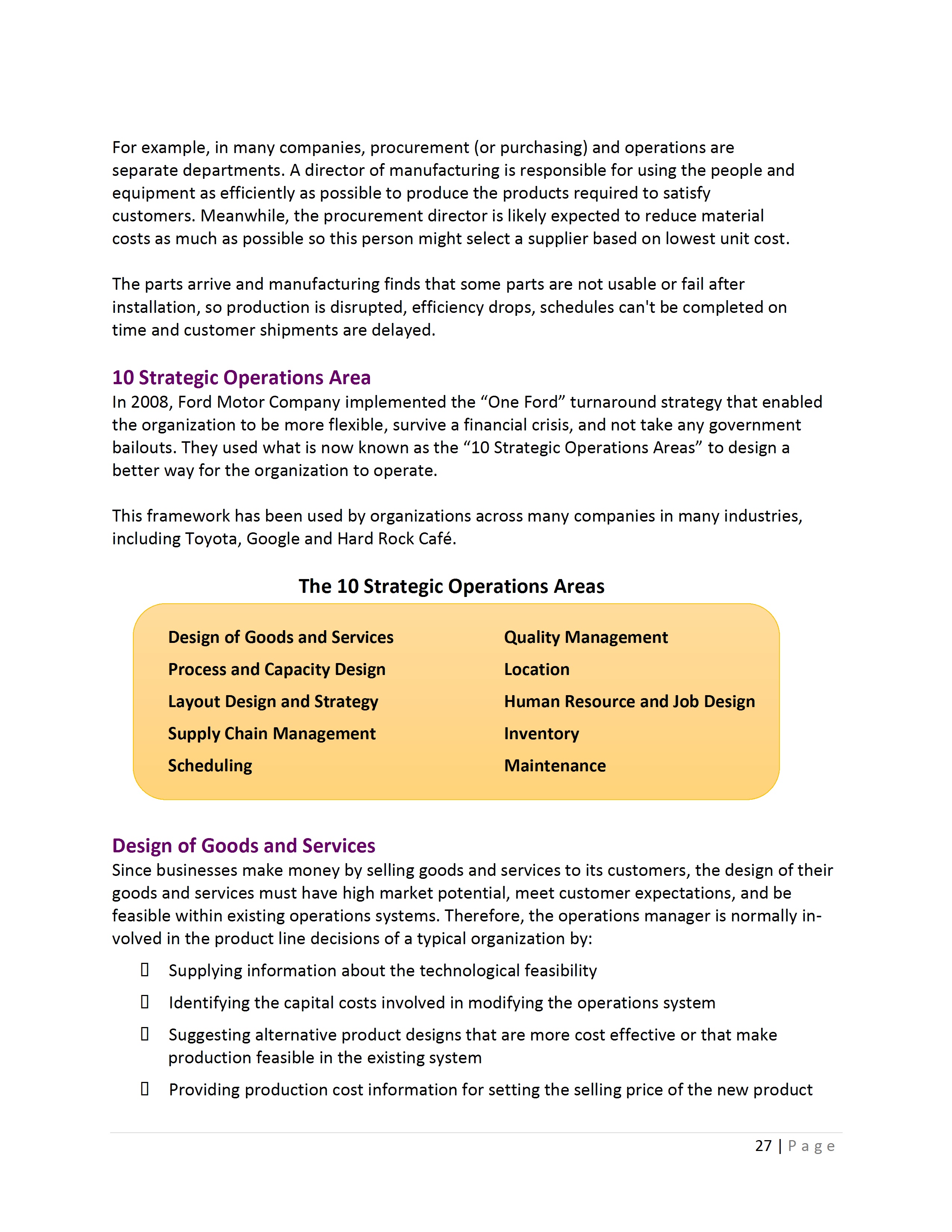

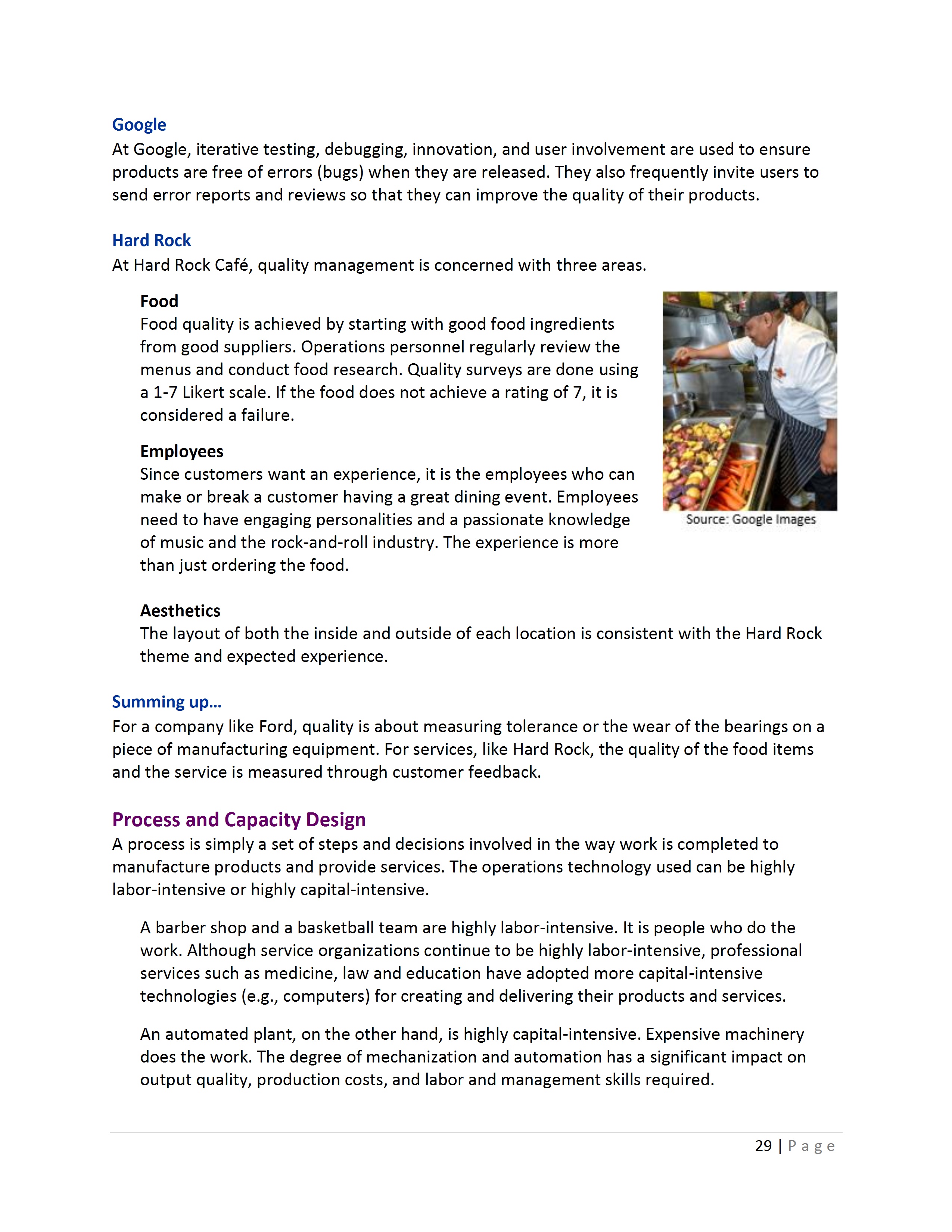

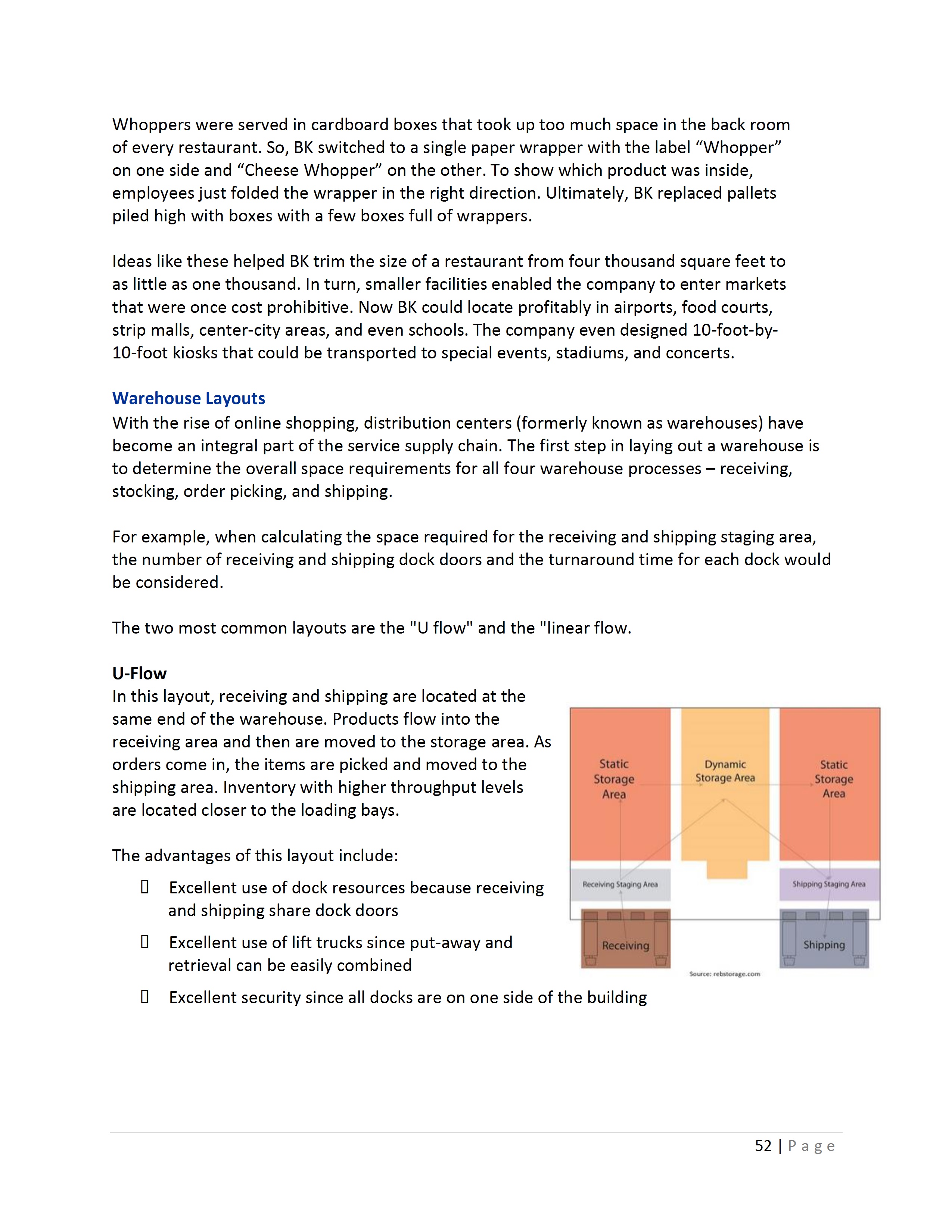

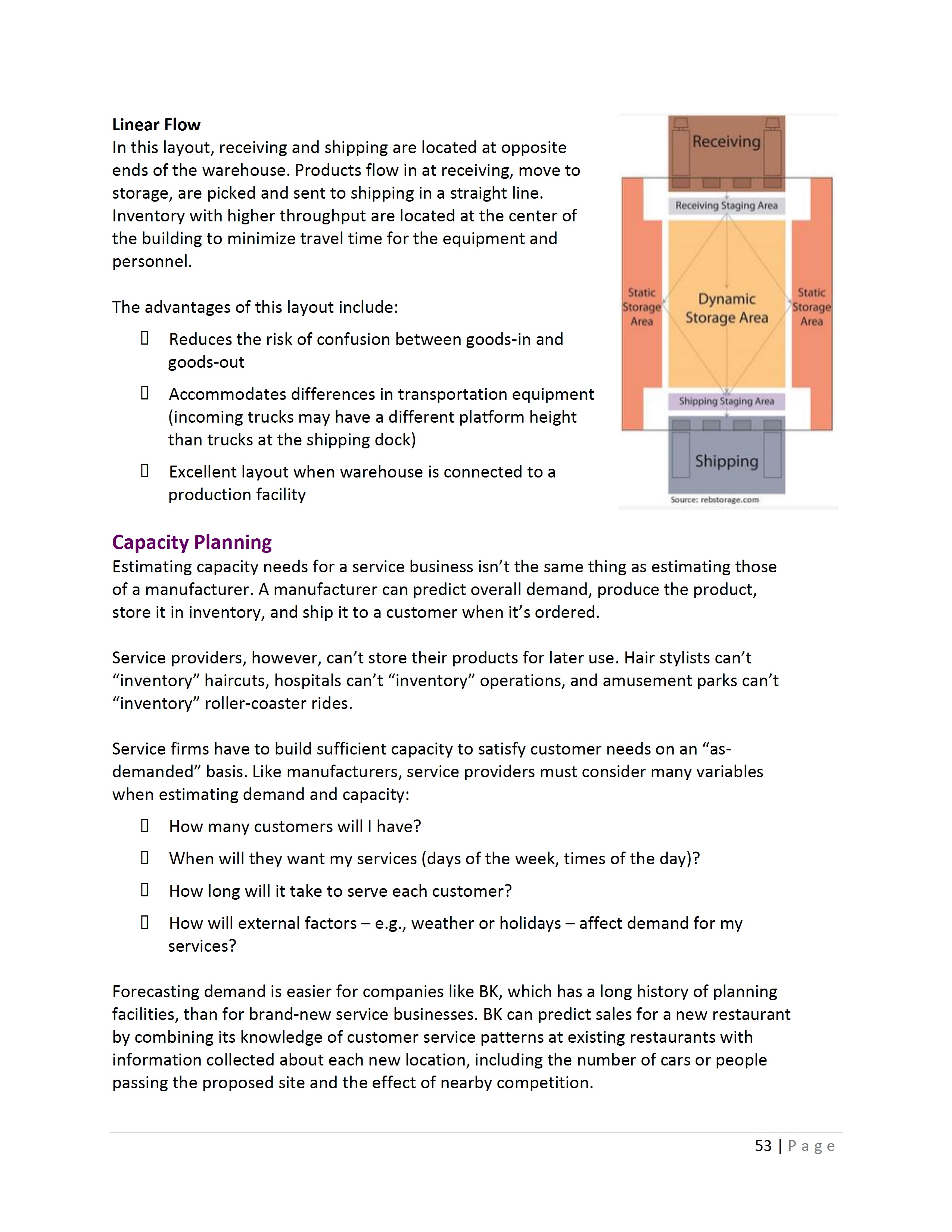

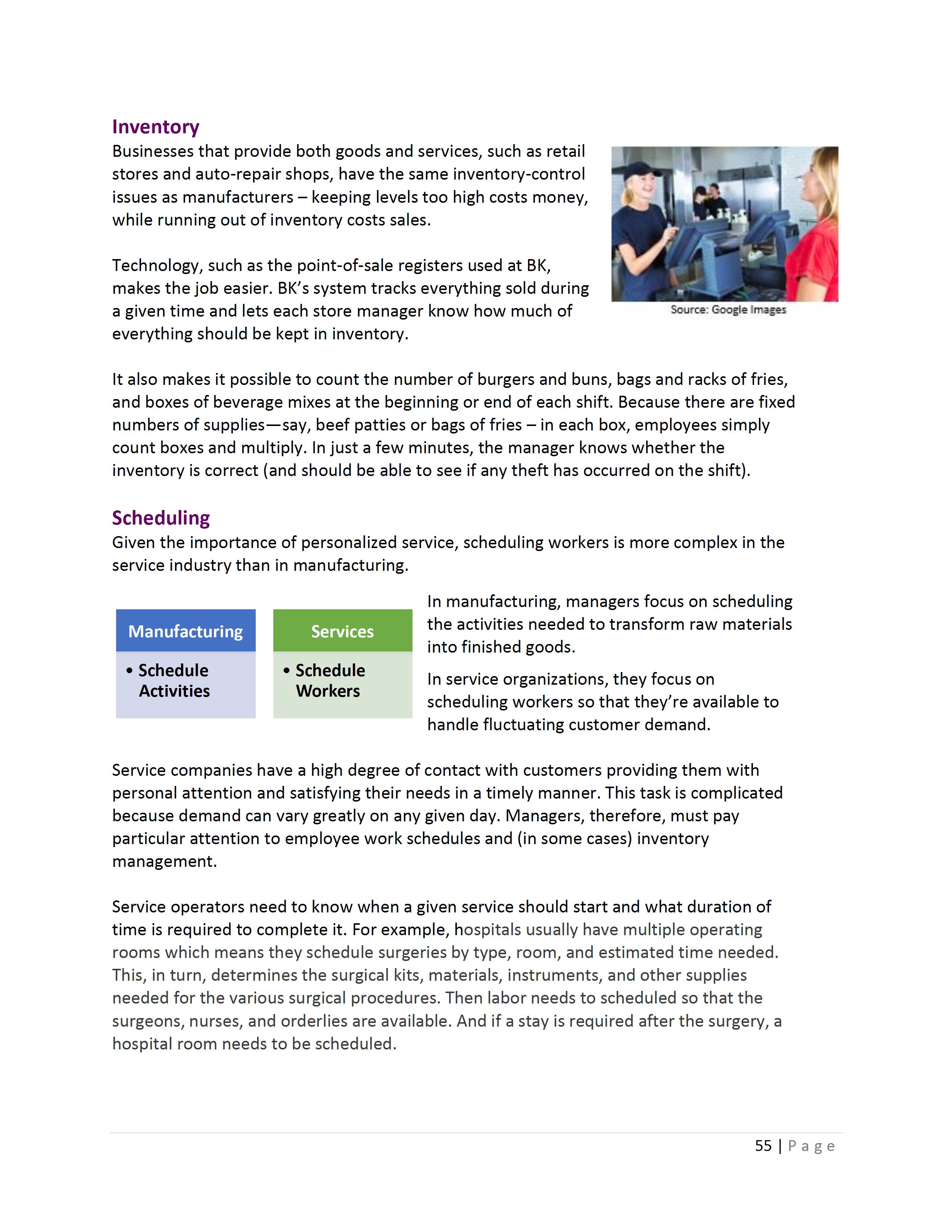

Unit 2: Designing the Operations Designing the operations of an organization or your department - precedes operational management. For .ll _ . example, suppose a wallet manufacture's mission is to ' "e . 'j\" provide higher quality handmade wallets. Bulk automation ' " 1 - with machines doesn't feed into this strategy. Maa\" \"n L \\ x-r/z a A Rather, you would want employees who have the skills to produce the handmade wallet so the costs may be more Source; Licensed Under cc svNcNo expensive because the labor costs go up. If that is the case, the company needs to consider increasing the price of the products or to reduce costs elsewhere in the company - perhaps in administrative areas. Ifthe design of your operation is done well and is documented, it becomes an integral component of an innovative, effective and efficient organization. Upon successful completion ofthis unit, you will be able to: l] Recognize the 10 strategic design considerations when planning your operation. Identify the decisions needed when designing an operation to produce goods. Identify the decisions needed when designing a service operation. Explain VOC and QFD. I:ll:ll:ll:l Recognize the trade-offs needed when designing an operation. To achieve these goals, Unit 2 covers these three chapters. Chapter 4: Design Considerations Chapter 5: Designing Production Operations Chapter 6: Designing Service Operations 25|Page Chapter 4: Design Considerations Chapter Overview All operating systems are influenced by the internal and external environment of the organization. The internal environment includes all the functional areas within the organization, each with its own policies, resources, forecasts, goals, assumptions and constraints. The external world outside the organization includes the legal, political, social and economic conditions within which it is operating, as well as the suppliers and customers of the organization. '37? '73 'x, ,W '7' I The design of a good or service operation should reflect customer ' . .\\ vi wants and needs, which are often termed customer requirements. \\ / p' &w '. When customer requirements are expressed in the customer's . @ PL // own words, the term used is the voice ofthe customer (VOC). The ? k 0 design process must then translate the VOC into specific technical I - EB features that characterize a design and provide the blueprint for 3\"\" \"E's\" \"wcn'c'w manufacturing a product or delivering a service. Quality function deployment (QFD) is a focused methodology for carefully listening to the VOC and then effectively responding to those needs and expectations. It can be applied to a specific manufactured good or service, or to the entire CBP. Trade-Offs Any decision is almost always a search for the most favorable or desirable solution that achieves the most benefit for the least cost. When faced with these decisions, there is seldom a completely right or completely wrong answer. Rather, it is a matter of choosing among a number of tradeoffs where there are good and bad aspects and consequences to every choice. Two examples are price and inventory. Pce For most products and services, a lower price will gain more sales and higher overall revenue, but since margins are smaller, the total profit may be lower. Or maybe not. There will be an optimum price that will generate the most profit. Make the price higher and diminished volume may lower total profit. Inventory Every company would like to lower inventory (it's a cost that doesn't generate profit). But inventory is necessary to provide customer service. Lower inventory means a greater risk of shortages and lost sales. There is a \"best" inventory level that provides the optimum balance between cost and service. Competing Priorities Just about every aspect of a business is subject to trade-offs. And the biggest problems for management are that it is often hard to see all of the consequences of a decision because of the complex interconnectedness of all the business operations. 26|Page For example, in many companies, procurement (or purchasing) and operations are separate departments. A director of manufacturing is responsible for using the people and equipment as efficiently as possible to produce the products required to satisfy customers. Meanwhile, the procurement director is likely expected to reduce material costs as much as possible so this person might select a supplier based on lowest unit cost. The parts arrive and manufacturing finds that some parts are not usable or fail after installation, so production is disrupted, efficiency drops, schedules can't be completed on time and customer shipments are delayed. 10 Strategic Operations Area In 2008, Ford Motor Company implemented the \"One Ford\" turnaround strategy that enabled the organization to be more flexible, survive a financial crisis, and not take any government bailouts. They used what is now known as the \"10 Strategic Operations Areas" to design a better way for the organization to operate. This framework has been used by organizations across many companies in many industries, including Toyota, Google and Hard Rock Caf. The 10 Strategic Operations Areas Design of Goods and Services Quality Management Process and Capacity Design Location Layout Design and Strategy Human Resource and Job Design Supply Chain Management Inventory Scheduling Maintenance Design of Goods and Services Since businesses make money by selling goods and services to its customers, the design of their goods and services must have high market potential, meet customer expectations, and be feasible within existing operations systems. Therefore, the operations manager is normally in- volved in the product line decisions of a typical organization by: l] Supplying information about the technological feasibility l] Identifying the capital costs involved in modifying the operations system I] Suggesting alternative product designs that are more cost effective or that make production feasible in the existing system I] Providing production cost information for setting the selling price of the new product 27|Page Ford Ford's goal in the design of goods and services area was to achieve global consistency in costs, quality, and resources across all business divisions. The One Ford mission required such consistency in goods and services. This condition contributed to Ford's financial efficiency and its ability to optimize customer satisfaction. Source: Google images Toyota Toyota addresses this strategic decision area through technological advancements and quality. The company uses its R&D investments to ensure advanced features in its products. Toyota also integrates dealership personnel needs in designing after-sales services. Google Google has different teams designing their offerings. Based on market research, trends, and future expectations, teams develop cutting-edge apps for desktop and mobile users. Hard Rock Hard Rock Caf knows its customers want an experience. So, they created a \"dining event\" that incorporated a visual and sound experience. The design of the goods and services included its food and drinks, music, memorabilia, rock concerts, and even a retail area where customers can buy Hard Rock merchandise. It does adapt the experience to the social norms and preferences of each location. Summing up... For Ford, the car must be designed, tested, and costed-out by engineers or operations managers. For a service business, such as Hard Rock, it is a chef who completes these tasks. Quality Management The main concerns in this strategic decision area are being clear on the customer's demands (market research) and then consistently meeting those expectations (quality assurance testing) to achieve high customer satisfaction. Customers lose faith in the company when the products and services lack quality and consistency which results in lost sales. Ford Ford does this through standard quality assurance practices, such as random batch tests on its products to ensure quality, market research to identify customers' quality expectations, continuous improvement in the production system, and worker involvement so production can be stopped at the first sight of defects. Toyota Toyota uses its Toyota Production System (TPS) to maximize quality. TPS is a management system that incorporates lean manufacturing (reducing waste) and justin-time production. The company adheres to the principles covered in The Toyota Way, which is a framework intended ensure continuous improvement and respect for people. 28|Page Google At Google, iterative testing, debugging, innovation, and user involvement are used to ensure products are free of errors (bugs) when they are released. They also frequently invite users to send error reports and reviews so that they can improve the quality of their products. Hard Rock At Hard Rock Caf, quality management is concerned with three areas. Food Food quality is achieved by starting with good food ingredients from good suppliers. Operations personnel regularly review the menus and conduct food research. Quality surveys are done using a 1-7 Likert scale. If the food does not achieve a rating of 7, it is considered a failure. Employees Since customers want an experience, it is the employees who can make or break a customer having a great dining event. Employees .7 1 need to have engaging personalities and a passionate knowledge Source. Google Images of music and the rock-and-roll industry. The experience is more than just ordering the food. Aesthetics The layout of both the inside and outside of each location is consistent with the Hard Rock theme and expected experience. Summing up... For a company like Ford, quality is about measuring tolerance or the wear ofthe bearings on a piece of manufacturing equipment. For services, like Hard Rock, the quality of the food items and the service is measured through customer feedback. Process and Capacity Design A process is simply a set of steps and decisions involved in the way work is completed to manufacture products and provide services. The operations technology used can be highly labor-intensive or highly capital-intensive. A barber shop and a basketball team are highly labor-intensive. It is people who do the work. Although service organizations continue to be highly labor-intensive, professional services such as medicine, law and education have adopted more capital-intensive technologies (e.g., computers) for creating and delivering their products and services. An automated plant, on the other hand, is highly capital-intensive. Expensive machinery does the work. The degree of mechanization and automation has a significant impact on output quality, production costs, and labor and management skills required. 29|Page The capacity decision is truly a high-risk one because you need to forecast future market demand. If you build capacity that exceeds your needs, you may use resource commitments (capital investment) that may never be recovered. Ifyou build a facility with a smaller capacity than expected demand, it may result in lost market opportunities. Yet that does free up capital resources that you can use for other projects. These kinds of trade-offs are inherent in the capacity decision. Ford Ford uses the assembly line method which maximizes production capacity. Also, Ford continues to improve its capacity by developing new facilities for its production network and supply chain. It is now focused on increasing its capacity for electric vehicles (EVs). This includes working with key suppliers and its own manufacturing facilities (Rawsonville Components Plant and Van Dyke Electric Powertrain Center) to find ways to increase capacity of parts needed for EVs, including battery cells, battery trays and electric drive systems. Toyota As mentioned, Toyota uses lean manufacturing, which is embodied in TPS. The company emphasizes waste minimization to maximize process efficiency and capacity utilization. Thus, Toyota supports business efficiency and cost-effectiveness in its process and capacity design. Google Google uses standard software development processes to address capacity design. The company works closely with the contract manufacturers so the design of their products (e.g., Pixel and Some; Gouge .mages Chrome) is based on their processes and capacities. Hard Rock Hard Rock makes product and service decisions based on efficiency, cost, quality, and labor requirements. The whole production process from receiving ingredients to storage to grilling, baking, or frying is meant to create a quality meal for the customer. The main issue restaurants, like Hard Rock, face is managing capacity. The Coronavirus crisis that shook the entire restaurant industry required more space between the tables which decreased capacity within the location. To maintain revenues and stay in business, many restaurants increased their take-out service which created the need make operating decisions for new processes and capacity needs. Summing up... For companies like Ford, process and capacity are focused on productivity and cost control. For companies like Hard Rock process and capacity are a function of fluctuating seasonal and time- of-day demand. 30|Page Location Location is a major long-term decision that can make or break a business. When deciding where to locate an operation, you face the dilemma of whether to locate facilities near sources of supply (input resources) or near customer markets (ease of output dispersal). This decision affects the capital cost of construction, the future costs of operations, and the reliability of service to customers. In developing a location strategy, you need to consider the supply chain and how the location will receive supplies, the movement of goods and services internally and to customers, and the role of marketing and public relations in the location choice. Ford Ford makes location decisions to ensure strategic benefits of all of its facility locations. The company's strategy involves regional production facilities, such as the Ford factories in Germany. On the other hand, dealership locations are based on market size. Toyota Toyota uses global, regional and local location strategies. For Tavern example, the company has localized manufacturing plants in the United States, China and Thailand, as well as official dealerships in '1 markets around the world. J Source. Gooye 'mages Google Since their web-based digital products are distributed online, location is a minimal consideration for Google. They do, however, maintain support facilities with offices around the globe. For their digital products like phones and notepads, location decisions are made by partnering with original equipment manufacturers (OEMs). Hard Rock Since a lot of their customers are tourists, Hard Rock is susceptible to economic fluctuations. That means location decisions consider such things as political risk, currency risk, social norms, brand fit, and business practices. Fixed and variable costs are used to calculate breakeven for several locations in order to systematically narrow down the search from country to city to the precise street corner. Summing up... Both Ford and Hard Rock look for locations with low variable and fixed costs as well are other factors mentioned. Ford would choose locations based on proximity to suppliers while Hard Rock would look for densely populated areas close to customers. 31|Page Layout Design and Strategy In this strategic decision area of operations management, ":7 f the objective is to maximize efficiency of workflows and or' ' ' 1:}. resources. And the choice of physical layout of a facility is _ ._ '- bf 7 Rig closely related to previous decisions on product or service ' .V] / line, capacity and operations technology. my. ?/// - -c / For example, an assembly line would be the best layout if large quantities of a product are mass produced. This type of layout, however, would not work with custom-made products. For an office, you need to consider the placement of desks, workstations, and how materials are delivered and used. Source: Google Images Ford Ford, and many other manufacturers, use an assembly line that involves creating the final product in sequential steps faster and with less labor. In addition, Ford uses robotics and other technology to automate its production facilities. There are critics ofthe assembly line, however, who complain that this manufacturing process compartmentalizes workers and simplifies their tasks to the point that theirjobs become tedious and less exciting. Toyota For Toyota, the plant layouts apply lean manufacturing principles (waste reduction) and the maximum efficiency of workflow. On the other hand, Toyota dealership layout design satisfies the company's standards but also includes customer requirements in the design. Google Google has a reputation for designing innovative and creative working environments. To develop its web-based products, Google integrates efficiency and creativity with efficient workflows. For its retail products, it uses contract manufacturers. Hard Rock Since Hard Rock wants to create a dining experience, every element of the design for the dining and bar areas must reinforce that mission by using memorabilia, music, visuals, lighting, sound, smells, and circulation paths for employees and customers. And the circulation path for customers exposes them to the merchandise for sale in the restaurant. The kitchen layout is designed to maximize efficiency, workflows, and output. For example, the \"salad maker\" can make a salad quickly because all the ingredients needed are within reach. Summing up... Because manufacturers do business out of plants rarely visited by customers, they base the size and layout of their facilities solely on production needs. In the service sector, however, most businesses must design their facilities with the customer in mind. That is, they must accommodate the needs of their customers while keeping costs as low as possible. 32|Page Human Resources and Job Design You often hear the saying, \"Employees are a company's biggest asset.\" Therefore, decisions about the types and amounts of human skills labor, managerial, and professional must be compatible with the choices made in the other strategic operations decisions. For example, these human resource decisions are closely related to location decisions, because the availability of different skills varies widely in different geographic regions. Source: Google Images Similarly, methods chosen for selecting, training and rewarding employees must be designed attract potential employees and motivate current ones. Highly motivated and satisfied employees are more productive, so companies need to make good decisions about providing competitive pay, a safe working environment, job empowerment, and supportive leadership. To achieve success in this area, companies also need to implement continuous improvement programs with regular reviews, provide continuous training for employees, and institute employee satisfaction programs. Ford Ford has the goal of maximizing human resource effectiveness and efficiency in this strategic decision area of operations management. Since the company has locations around the world, Ford focuses on drawing strength from diverse culture and backgrounds. Plus, some HR policies and practices are guided by union contracts. The company ensures continuous improvement and personnel development in its strategies. Toyota The company applies The Toyota Way and TPS for this strategic decision area of operations management. The firm emphasizes respect for all people in The Toyota Way, and this is integrated in HR programs and policies. Also, Toyota has training programs based on TPS to ensure lean manufacturing practices. Google In addition to experience, Google's HR management focuses on smartness and excellence among employees. The company provides high salaries and incentives such as free meals as a way to attract and retain talent. Hard Rock Like many companies, Hard Rock employs a wide range of talent chefs and other kitchen help, wait staff, bartenders, merchandisers, coordinators and performers for the live music, and maintenance staff. Since turnover is common in the restaurant business, HR and management pay close attention to recruiting the talent needed. 33|Page In choosing its employees, in addition to competency, staff members must be passionate about music, love to serve, tell a story, and ensure customers have the intended experience. And once hired, HR focuses retention through training and constant development of its employees. Summing up.... An auto assembly line focuses on hiring skilled factory workers while service businesses focus on those with personality and a passion for delivering great customer experiences. Supply Chain Management 6 Supply chain management faces many challenges such as the Covid pandemic, labor shortages, extreme weather conditions, unexpected wars, and changes in foreign relations resulting in IE? sanctions. Supply chain managers constantly assess and determine h, the best strategies to streamline the supply chain, be cost 5% if.) effective, and develop trusted partners. M Source: Google Wages Vertical integration occurs when a business takes control of one or more stages of the supply chain by acquiring a producer, vendor, supplier, distributor, or other related company within the same industry. Companies that choose to integrate vertically do so to strengthen their supply chains, reduce their production costs, capture upstream or downstream profits, or access new distribution channels. Companies can integrate vertically by moving backward or forward. Backward integration occurs when a company decides to buy another business that makes an input product for the acquiring company's product. For example, Apple manufactures the chipset used in its popular devices. By doing so, the company has succeeded in keeping a check on the quality and cost of chipsets which ultimately helps the company and its customers by providing quality products at better prices. Forward integration occurs when a company decides to take control of the post-production process. For example, Apple opened retail stores to sell its entire product offering. By doing so, the company saves the commissions it pays to its retail partners, maintains uniformity in the layout of its stores, and is able to provide better price points to its customers. Ford Ford's supply chain is global and involves company-owned production facilities, as well as third parties. The company-owned facilities, such as those in the Ford River Rouge Complex in Michigan, are a result of Ford's backward vertical integration strategy. This strategy empowers Ford to control the supply of some of the materials used for manufacturing its vehicles. And as it transitions from internal combustion engines (ICEs) to electric vehicles (EVs), Ford has decided to vertically integrate the electric motors and converters. 34|Page Toyota Toyota uses lean manufacturing for supply chain management and automation systems for real-time adjustments in supply chain activity. In this way, Toyota minimizes the bullwhip effect in its supply chain. By combining the inbound manufacturing parts and after-market/service parts divisions into a single division, operational efficiencies and savings with suppliers are realized. Google At its core, Google is a data collecting organization and is almost completely vertically integrated. For example, a person searching can use the Google Chrome web browser and the search can travel to a Google data-center entirely over a Google infrastructure. _. no. Source; Google Images At the Google data-center (owned and operated by Google), proprietary software is used to index and store the search. When the search query is satisfied, advertising is selected from the Google-owned search advertising system, and assembled along with search results which make their way back to the person requesting the search. In addition to this vertical integration, Google has significant breadth Google Drive for cloud storage, Google docs for working with documents and spreadsheets, Google picture storage systems, music, software shops, book distribution, and on and on. Hard Rock For the food-service business at Hard Rock, managing suppliers is a top concern because high quality ingredients (chicken, pork, beef, eggs) are needed to create fresh and high-quality meals. The food safety, and freshness and rapid response are some of the main criteria for selection of suppliers. In fact, menu items are only put into production if the ingredients are available from qualified suppliers. Contracts for meat and poultry are negotiated and signed months in advance. The same is true with the merchandise it sells in the retail area ofthe location. Items like leather jackets can have up to a 9-month lead time. Summing up... A classic supply chain (e.g, Ford) moves from upstream to downstream, where the raw material is transformed into products, moved through logistics and distribution to final customers. A data supply chain (e.g, Google) moves in the opposite direction. The raw data is \"sourced\" from the customer/user and gets processed and refined by proprietary algorithms and stored in data centers. 35|Page The idea in supply chain management is that the closer you get to the customer (in case you're a manufacturer) or the closer you get to the producer of a good or service (if you're a retailer) or the closer you get to primary access point to acquire data from consumers (e.g., Google), the more control you have over the whole experience. This, in turn, might allow you to dominate your industry overtime and keep tight control over processes, quality, and operations. Inventory Inventory is an expensive asset. Holding too much inventory reduces cash flow or the inventory could become obsolete. Yet sufficient inventory ensures quicker response time to customer orders. Safety stock acts as a buffer in case supplier shipments are delayed. ' _ \" Good inventory management helps a company reduce costs and 35 ' ' T'r' , efficiently manage production. The objective is to strike a balance between inventory investment and customer service. Companies Ve/77L ;" . or}, ,: must carefully control critical items, keep accurate records, count inventory regularly, and avoid theft and damage. This is difficult as many factorssuch as weather, supply shortages, and laborall k a influence how an organization maintains its inventory. Source. Google images Ford Ford's inventory management supports just-in-time manufacturing methods, which require continuous monitoring to adjust the inventory and minimize its costs. Ford's also makes market-based inventory decisions as different markets present different challenges. Toyota In addressing this strategic decision area, Toyota minimizes inventory levels through just-in- time inventory management. The aim is to minimize inventory size and its corresponding cost. This inventory management approach is covered in the Toyota Production System (TPS). Google Google's use automated monitoring and control of inventory as part of its inventory management process. Automating the management of its web-based and software products is especially important. Hard Rock Hard Rock needs to ensure that all the foods and drinks do not exceed the expiration date and are available to meet customer demand. This requires that food turnover is quick and that inventory is rotated to ensure freshness. And to protect customer safety, food in inventory must be maintained at the appropriate temperature. Summing up... In a manufacturing plant, like Ford, inventory is a cost and consists of the components used to build the finished product and the finished product themselves. Inventory does nothing for the business until it is sold in exchange for money. On the other hand, inventory in service is quite intangible like the dining experience at Hard Rock. 36|Page Scheduling Scheduling means you consider how much product must be made to meet customer demand. And how many people and machines are required to do the job effectively and efficiently. This differs among industries and business departments. For example, hospital emergency rooms need to maintain different schedules than the corporate office. In this strategic decision area of operations management, the short-term and intermediate schedules of processes and resources are considered. Source: Google Images Ford Ford addresses these concerns through automated scheduling in its production facilities, and semi-automated scheduling in its corporate and regional offices. Toyota Toyota follows lean manufacturing principles in its scheduling in order to minimize operating costs. Cost-minimization is maintained through people resource scheduling that change according to market conditions. Google Automated processes, such as checking productivity levels, are used by Google. It also uses flexible scheduling approaches for office activities to match employee availability. Hard Rock Scheduling employees is based on sales forecasts which are based on recent sales trends, community events happening nearby, and seasonality. The goal is to always have capable and available staff to serve its customers on time for daily businesses and important periodical events. Managers also consider the seniority of employees in filling the daily schedule as their experience translates to higher productivity and profits. Summing up... Scheduling materials for production is a major concern for a manufacturing plant like Ford. On the other hand, scheduling staff to create a great dining experience is critical for a service business like Hard Rock. Maintenance Just like you check the oil in your car on a regular basis, this is the on-going care and servicing of equipment to ensure it is working properly or to detect any potential failure. These can be preventive, such as scheduled maintenance checks to prevent a breakdown. Corrective maintenance, or equipment repair, deals with a malfunction or failure after it has occurred. This area also includes ensuring employees are trained and engaged in the work being done. 37|Page Ford Ford addresses this goal through a combination of strategies for HR, IT, manufacturing and other areas, as well as maintenance teams for facilities and other assets. Toyota The company has a global HR network that supports flexibility and business resilience. Thus, in this strategic decision area of operations management, Toyota uses its global business reach to ensure optimal and stable productivity. Source: Google Images Google The company maintains it computer systems, servers, and facilities through dedicated maintenance teams. Hard Rock Hard Rock practices both preventive and corrective maintenance to keep maximum efficiency and reliably provide all products as advertised. The Caf doors must be opened on-time daily and the kitchen ready to provide hot food served hot and cold food served cold. Bar equipment, point-of-sale equipment, and furniture must be in good working order. Summing up... Maintenance is critical in an auto plant, like Ford, as there is often little alternative in routing and downtime on an assembly line is expensive. In a service business, the focus in on ensuring employees maintain their skills and positive outlook. Summary These 10 areas can be applied to any size business, not just global giants such as Ford and Jet Blue. Use them as a guide to analyze your operations. Measure your current productivity and then implement strategies to operationalize these 10 areas into your decision-making process and watch your productivity become more efficient. Sources for this chapter include: https://lawaspect.com/lO-decisions-operations-management-applied-hard-rock-caf/ https://www.talentaIign.com/lOstrategicoperationsbusinessandpeopIeoperations/ https://www.managementnote.com/which-of-these-is-not-oneof-the-lO-strategic-om-decisions/ https://panmore.com/toyota-operations-management-10-decisions-areas-productivity https://panmore.com/googIelOdecisionsareasoperationsmanagementproductivity 38|Page Chapter 5: Designing Production Operations Chapter Overview All manufacturers set out to transform resources into finished goods. And while doing this, they must continually strive to improve operational efficiency, fine-tune their production processes to focus on quality, hold down the costs of materials and labor, and eliminate all costs that add no value to the finished product. With these factors in mind, this chapter addresses a number of the strategic decisions covered in Chapter 4. Making those decisions is the job of the person managing the operation and includes production planning, production control, and quality control. Production Planning At the strategic level, production planning determines how goods will be produced, where production will take place, and how manufacturing facilities will be laid out. These decisions have long-range implications and are crucial to a firm's success. Production Control Once the production process is under way, managers must continually schedule and monitor the activities that make up that process. They must solicit feedback and then adjust when and where needed. At this stage, they also ensure the purchasing of raw materials and the handling of inventories are both accurate. Quality Control Finally, the operations manager is directly involved in efforts to ensure that goods are produced according to specifications and that quality standards are maintained. Getting Started Before making decisions about the operations processes, managers must consider the strategic goals of the organization. I] Does the company intend to be a low-cost producer and compete on price? I] Or does it plan to focus on quality and go after the high end of the market? I] Does it want to build a reputation for reliability? I] What if it intends to offer a wide range of products? 39|Page To make things even more complicated, all these decisions involve trade-offs. Upholding a reputation for reliability isn't necessarily compatible with offering a wide range of products. Low cost doesn't normally go hand-in-hand with high quality. Site Selection In choosing a location, managers must consider several factors: I] They often want to locate plants close to suppliers, customers, or both, to minimize shipping costs, both for raw materials coming into the plant and for finished goods going out. I] They generally want to locate in areas with ample numbers of skilled workers. I] They naturally prefer locations where they and their families will enjoy living. I] They want locations where costs for resources and other expensesland, labor, construction, utilities, and taxesare low. I] They look for locations with a favorable business climateone in which, for example, local governments might offer financial incentives (such as tax breaks) to entice them to do business in their locales. Proximity to Sources of Supply Firms that process bulk raw materials usually locate close to the source of supply to reduce transportation costs. Paper mills locate close to forests, canneries are built close to farming areas, and fish processing plants are located close to the harbors where the fishing vessels dock. Proximity to Customers There are several reasons why an organization would locate close to end-customers. Service firms need to be close to customers to be convenient, as is the case for grocery stores, gas stations, fast food restaurants, and hospitals. Transportation costs can also require proximity to customers, as in the case of concrete manufacturing. Perishable products often require that they be produced close to the final market, as is the case for bread, milk, and fresh flowers. Source: Google Images Community Factors Communities may offer a number of incentives to entice companies, including waiving or reducing taxes, and providing access roads, water and sewer connections, and utilities. Community attitudes can also play a role in an organization's location decision. Some communities may actively discourage companies that might bring more pollution, noise, and traffic to the area. Some communities may not want a prison to be located in their community. Other communities may welcome such firms because of the jobs, tax revenues, and economic diversity they promise. 40|Page Labor Factors Research shows that the majority of location decisions are largely based on labor factors, since labor is a critical variable for many firms. Labor factors include the prevailing wage rate in a community for similar jobs, the supply of qualified workers, and the average education level ofthe local population e.g., percentage of high school graduates. Other labor factors can include the degree of union organizing and the general work ethic of a community. Measures of absenteeism, and worker longevity in a job can also play a strong role when a firm makes a location decision. Other Factors Many other factors can play a role in the location decision, including quality of life (crime rates, good schools, climate, and recreation options), access to major transportation arteries, construction costs, proximity of the competition, and opportunities for future expansion. Making the Decision As mentioned earlier, the importance of any location factor can vary greatly, depending on the circumstances of the decision. Managers rarely find locations that meet all these criteria. As a rule, they identify the most important criteria and aim at satisfying them. In deciding to locate in San Clemente, California, for instance, PowerSki was able to satisfy three important criteria: .y.' __ Pouverski Jetboard is a motorized l] proximity to the firm's suppliers. Surfboard that combines wakeboarding and surfing. l] availability of skilled engineers and technicians. l] favorable living conditions. These factors were more important than operating in a low-cost region or getting financial incentives from local government. Because PowerSki distributes its products throughout the world, proximity to customers was also not that important. Facility Design When deciding on plant layout, the focus is on how equipment, machinery, and people will be arranged to make the production process as efficient as possible. In this section, we'll examine four types of facility layouts: product, process, cellular, and fixed position. Product Layout In a product layout, high-volume goods are produced efficiently by people, equipment, or departments arranged in an assembly line. Paced lines move output along at a continuous rate so that workers can perform their work as the product goes by. Unpaced lines allow a variable work pace. 41|Page Just Born, a candy maker located in Bethlehem, Pennsylvania, makes a product called Marshmallow Peeps on an assembly line. First, the ingredients are combined and whipped in huge kettles. Then, colored sugar is added. At the next workstation, the mixture colored warm marshmallow is poured into baby-chick shaped molds carried on conveyor belts. The candy pieces on the conveyor belts then move forward to stations where workers add eyes or other details. When the finished candy reaches the packaging area, it's wrapped for shipment to stores around the world. Combining Sugar-added and whipping coloring Wrapping and shipping Detailing Process Layout The process layout groups together workers or departments that perform similar tasks. Goods- in-process (goods not yet finished) move from one workstation to another. At each position, workers use specialized equipment to perform a particular step in the production process. An example is the production process at the Vermont Teddy Bear Company. Let's say you place an order for a personalized teddy bear a l'hiker bear\" with khaki shorts, a white T-shirt with your name embroidered on it, faux-leather hiking boots, and a nylon backpack with sleeping bag. Your bear begins at the fur-cutting workstation, where its honey- brown \"fur\" coat is cut. It then moves to the stuffing and sewing workstation to get its insides and have its sides stitched together. Next, it moves to the dressing station, where it's outfitted with all the cool clothes and gear that you ordered. Finally, it winds up in the shipping station and starts its journey to you. Fur-Cutting Stufng and sewing Shipping 42|Page Both product and process layouts arrange work by function. At the Vermont Teddy Bear Company, for example, the cutting function is performed in one place, the stuffing-and-sewing function in another place, and the dressing function in a third place. Ifyou're a cutter, you cut all day; if you're a sewer, you sew all day that's your function. The same is true for the production of Marshmallow Peeps. If your function is to decorate peeps, you decorate all day on the assembly line. If your function is packing, you pack all day. Cellular Layout Arranging work by function, however, isn't always efficient. Production lines can back up, inventories can build up, workers can get bored with repetitive jobs, and time can be wasted in transporting goods from one workstation to another. To counter some of these problems, many manufacturers have adopted a cellular layout, in which small teams of workers handle all aspects of building a component, a \"family\" of components, or even a finished product. Each team works in a small area or cell equipped with everything that is needed to function as a self-contained unit. Machines are sometimes configured in a U-shape, with people working inside the U. Because team . . l members often share duties, they're trained to \" Emu oyee . _ _> Workow perform several different jobs. Q Task in the manufacturing process Teams monitor both the quantity and the quality of their own output. This arrangement often results in faster completion time, lower inventory levels, improved quality, and better employee morale. Cellular manufacturing is used by large manufacturers, such as Boeing, Raytheon, and Pratt & Whitney, as well as by small companies, such as Little Enterprise, which makes components for robots. Fixed Position It's easy to move teddy bears and marshmallow candies around the factory while you're making them, but what about airplanes or ships? In producing large items, manufacturers use a fixed- position layout in which the product stays in one place and the workers (and equipment) go to the product. This is the arrangement used by General Housing Corporation in constructing modular homes. Each house is constructed at the company's factory in Bay City, Michigan, according to the customer's design. 43|Page Because carpenters, electricians, plumbers, and others work on each building inside the climate-controlled factory, the process can't be hindered by weather. Once it's done, the house is transported in modules to the owner's building site and set up in one day. Capacity Planning Source: Creative Commons You also have to decide on the quantity of products that you'll produce and you begin by forecasting demand for your product. Forecasting isn't easy. To estimate the number of units that you're likely to sell over a given period, you have to understand the industry that you're in and estimate your likely share of the market by reviewing industry data and conducting other forms of research. Once you've forecasted the demand for your product, you can calculate the capacity requirements of your production facility the maximum number of goods that it can produce over a given time under normal working conditions. In turn, having calculated your capacity requirements, you're ready to determine how much investment in plant and equipment you'll have to make, as well as the number of labor hours required for the plant to produce at capacity. Like forecasting, capacity planning is difficult. Unfortunately, failing to balance capacity and projected demand can be seriously detrimental to your bottom line. If you set capacity too low and produce less than you should, you won't be able to meet demand, and you'll lose sales and customers. If you set capacity too high and produce more units than you should, you'll waste resources and inflate operating costs. Production-Method Decisions The first step in production planning is deciding which type of production process is best for making the goods that your company intends to manufacture. One way to appreciate the nature of this decision is by comparing three basic types of processes or methods: make-to- order, mass production, and mass customization. The task of the operations manager is to work with other managers, particularly marketers, to select the process that best serves the needs of the company's customers. Make-to-Order At one time, most consumer goods, such as furniture and clothing, were made by individuals practicing various crafts. By their very nature, products were customized to meet the needs of the buyers who ordered them. This make-to-order strategy is still commonly used by such businesses as print or sign shops that produce low-volume, high-variety goods according to customer specifications. 44|Page Mass Production Mass production is a make-to-stock or make-and-sell strategy. This is the practice of producing high volumes of identical goods at a cost low enough to price them for large numbers of customers. Goods are made in anticipation of future demand (based on forecasts) and kept in inventory for later sale. This approach is particularly appropriate for standardized goods ranging from processed foods to electronic appliances. Mass Customization The disadvantage of mass production is that customers have to accept standardized products. Yet, increasingly customers are looking for products designed to accommodate individual tastes or needs but can still be bought at reasonable prices. To meet the demands of these consumers, companies are turning to mass customization, which combines the advantages of customized products with those of mass production. This approach requires a company to interact with the customer to find out exactly what the customer wants and then manufacture the good, using efficient production methods to hold down costs. One efficient method is to mass-produce a product up to a certain cut-off point and then to customize it to satisfy different customers. More About Mass Customization The list of companies devoting at least a portion of their operations to mass customization is growing steadily. One example is Nike, which has achieved success by allowing customers to configure their own athletic shoes, apparel, and equipment through the Nike By You program. The Web has a lot to do with the growth of mass customization. l] Levi's lets you choose perfect fittingjeans by going through an online fitting process that first identifies your body type. I] Oakley offers customized sunglasses, goggles, watches, and backpacks. l] Mars, Inc. can make M&M's in any color the customer wants (e.g., school colors) as well as add text and pictures to the candy. l Naturally, mass customization doesn't work for all types of goods. Most people don't care about customized dish detergents or paper towels. 50\"\" 6W?" \"'55\" And while many of us like the idea of customized clothes, footwear, or sunglasses, we often aren't willing to pay the higher prices they command. Inventory Inventory is a cost. Excessive inventory means the company has money invested that earns no profits for the firm. In addition, excessive inventory incurs extra handling and holding costs. Not having enough inventory means the firm does not enough raw materials for production which, in turn, means there may not be enough goods for customers to purchase. 45|Page Most manufacturing organizations usually divide their inventory into three categories: raw materials, work-in- process, finished goods, Raw Materials A good purchased as a raw material includes materials and components scheduled for use in making a product. Because , materials are one of the largest sources of cash outlay in any 3W\": Licensed under\" BY'SA'NC manufacturing firm, it is the purchasing department (procurement) that is responsible for acquiring both direct and indirect raw materials. Direct: Raw materials that make up the thing being manufactured like the wax for a candle or coffee beans for ground coffee. Indirect: Raw materials used during production but are not part of the finished product such as cleaning supplies, batteries, tools, and services. In addition, purchasing must ensure quality, delivery performance, low cost, and technical support. Moreover, purchasing must continually seek new suppliers and products, and be able to evaluate their strategic, market, and economic potential to the company. Work-in-Process (WIP) WIP inventory are the materials and components that have started their transformation to finished goods but are still in the process of being made. Monitoring WIP is important for optimizing manufacturing capacity and inventory control. Unless it is part of a safety stock or buffer inventory strategy, WIP should be kept streamlined and consistent because it ties up cash. Since it is not liquid like raw materials, having too much WIP inventory can affect investments, loan approval, and future strategy. Finished Goods Finished goods have completed the transformation process but have not yet been sold or distributed to the end-user. These are goods ready for sale to customers. Keep in mind, though, that the term \"finished\" is relative as the finished good from one company may act as a raw material component for producing a product at another company. Finished goods show up on the company's balance sheet as a current asset and is a gauge for cash flow and inventory liquidity. Your finished goods numbers are needed in order to calculate turnover which a measure of how quickly a com pany's finished products are sold. Scheduling Scheduling is done to determine when resources such as employees and equipment should be assigned to work. Production schedules need to ensure that enough product is available for both retail and wholesale customers. Labor schedules need to ensure that the right number of workers with the right skills are available for the production process. 46|Page Production scheduling revolves around the movement and location of materials, parts, and subassemblies and when to assign resources (i.e., employees, equipment) to accomplish the work most efficiently. For make-to-order industries, order backlogs provide the needed customer-demand information. That is, you have known customer orders (called firm orders) that determine the Source. licensed under cc BV-SA-NC production and labor schedules. In industries where subassemblies and components are assembled in many different combinations to produce a large variety of end products, schedules are usually developed for the basic subassemblies and not for the ultimate finished goods. A final assembly schedule (FAS) defines the quantity and timing for assembling subassemblies and component parts into a final finished good. Quality In manufacturing, quality is defined as conformance to specification. No two products or characteristics, however, are ever exactly the same, because any process contains many sources of variability. In mass-manufacturing, traditionally, the quality of a finished article is ensured by post- manufacturing inspection of the product. Each article (or a sample of articles from a production lot) may be accepted or rejected according to how well it meets its design specifications. Statistical Process Control (SPC) Rather than just measuring the final output, SPC is a method of quality control which employs statistical methods to monitor and control a process. It emphasizes early detection and prevention of problems, rather than the correction of problems after they have occurred. This results in less waste (rework or scrap). The frequency of the inspections is determined by identifying any expected changes in the 5 M&E conditions (Man, Machine, Material, Method, Movement, Environment). You also need to consider the wear rate of parts used in the manufacturing process (machine parts, jigs, and fixtures). Example Assume that you work for Kellogg's, the maker of Raisin Bran cereal. You know that it's the company's goal to pack two scoops of raisins in every box of cereal. How can you test to determine whether this goal is being met? 47|Page You could use a statistical process control method called a sampling distribution. On a periodic basis, you would take a box of cereal off the production line and measure the quantity of raisins in the box. Then you'd compare actual quantities of raisins with the desired two scoops. If several samples in a row are low on raisins, you'd shut down the production line and take corrective action. Source. Geog-2 rages Any source of variation at any point of time in a process will fall into one of two classes. I] Common Causes These are non-assignable and normal sources of variation that consistently acts on process. These types of causes produce a stable and repeatable distribution over time. I] Special Causes These are assignable sources of variation that affects only some ofthe process output. They are often intermittent and unpredictable. Let's go back to a breakfast cereal example. Suppose a breakfast cereal packaging line is designed to fill each cereal box with 500 grams of cereal. Some boxes will have slightly more than 500 grams, and some will have slightly less. When the package weights are measured, the data will demonstrate a distribution of net weights. As the cams and pulleys of the machinery wear (a common cause variation), the cereal filling machine may put more than the specified amount of cereal into each box. Although this might benefit the customer, from the manufacturer's point of view, this is wasteful and increases the cost of production. If the manufacturer finds the change and its source in a timely manner, the change can be corrected (for example, the cams and pulleys replaced). Summary Businesses want to design the products that consumers demand. The process of moving an idea from concept to reality is the design process. And once a product is designed and in production, there needs to be a commitment to making constant improvements in the design, production, and delivery of goods and services. While manufacturing firms are different from service firms, both types of businesses must complete many of the same activities in order to be successful. That is, both must plan, design, execute, evaluate, improve, and redesign their products and services in order to provide exactly what their customers want. 48|Page Chapter 6: Designing Service Operations Chapter Overview As the U.S. economy has changed from a goods producer to a service provider, the predominance of the manufacturing sector has declined substantially over the last sixty years. Services operations often encounter different opportunities and challenges than tangible goods, and thus require unique operational considerations. Though the primary function of both manufacturers and service providers is to satisfy customer needs, there are several important differences between goods and services: intangibility, inventory, inseparability, inconsistency, and involvement (Chapter 1). Sourze: Mense-d order CC EV Getting Started When starting or expanding operations, businesses in the service sector must make a number of decisions quite similar to those made by manufacturers: I] What services (and perhaps what goods) should they offer? I] How will they provide these services? I] Where will they locate their business, and what will their facilities look like? I] How will they forecast demand for their services? For a service firm, planning and design begins with determining who the customer is and what needs the customer has. After customer needs are identified, the next step for successful service firms is to develop a plan that will enable the firm to deliver the services that their customers want or need. Design For example, a swimming pool repair business must design an operation Decisions that includes a process for hiring and training qualified employees, . Location obtaining necessary parts and supplies, marketing the firm's services, ._ . and creating management and accounting systems to control the firm's - Faculltles . . . . actIVItIes. - Capacuty ' Processes Designing operations is just as critical on the service side as it is on the Inventory product side. While there are countless considerations to be made, ' Scheduling many of which are unique to specific organizations or industries, this ' Quality chapter covers some of the strategic considerations when designing a service business. 49|Page Location (Site Selection) People in the real estate industry often say that the three most important factors to consider when you're buying a home are location, location, location. The same principle applies when you're trying to locate a service business. To be successful in a service industry, you need to be accessible to your customers. Some service businesses, such as ca ble-TV providers and package-delivery services go to their customers. Many others, however hotels, restaurants, stores, hospitals, and airports have to attract customers to their facilities. These businesses must locate where there's a high volume of available customers. For Burger King (BK), a favorite catchphrase among the planners who are looking for a promising spot for a new restaurant in the United States is, \"Through the light and to the right.\" In picking a location, BK planners perform a detailed analysis of demographics and traffic patterns, yet the most important factor is usually traffic count the number of cars or people that pass by a specific location in the course of a day. In the United States, where we travel almost everywhere by car, BK looks for busy intersections, interstate interchanges with easy off and on ramps, or primary destinations such as shopping malls, tourist attractions, downtown business areas, or movie theaters. In Europe, where public transportation is much more common, planners focus on subway, train, bus, and trolley stops. Sauna: Coog'e Images Once planners find a site with an acceptable traffic count, they apply other criteria. It must, for example, be easy for vehicles to enter and exit the site, which must also provide enough parking to handle projected dine-in business. Local zoning must permit standard signage, especially along interstate highways. Finally, expected business must be high enough to justify the cost of the land and building. Facilities When starting or expanding a service business, owners and managers must invest a lot of time in selecting a location, determining its size and layout, and forecasting demand. A poor location or a badly designed facility can cost customers, and inaccurate estimates of demand for products can result in poor service, excessive costs, or both. Size and Layout Because manufacturers do business out of plants rarely visited by customers, they base the size and layout of their facilities solely on production needs. In the service sector, however, most businesses must design their facilities with the customer in mind. That is, they must accommodate the needs of their customers while keeping costs as low as possible. 50|Page Servicescapes is a term developed by Booms and Bitner to describe the physical environment of the service encounter. It should cater simultaneously to the needs of employees as well as the customers. And for customers, servicescapes influence the impression customers have ofthe business. Servicescapes are composed of three dimensions: Ambient Conditions These are background characteristics of the environment that are meant to satisfy our five senses. Ambient conditions include items such as temperature, lighting, noise, music, and scent. The goal is to achieve consistency in brand atmospherics. That is why Starbucks focuses on the smell of coffee in their locations. Spatial Layout and Functionality This is about the physical surroundings such as the positioning of equipment or furniture and the size, shape, and spatial relationship among the objects. It includes exterior and interior facility design. Notice how you can recognize a restaurant just by the shape, size, and color scheme of the building. Their functionality is the ability of these items to support the customer experience. Signs, Symbols, Artifacts Source: Licensed underw These clues communicate information and messages about the environment and the business to the customer. The signage, parking, design/decor, and appearance of fellow consumers and staff all send sensual clues about the experience. Keeping with the restaurant example, when you approach the establishment, you unconsci

Step by Step Solution

There are 3 Steps involved in it

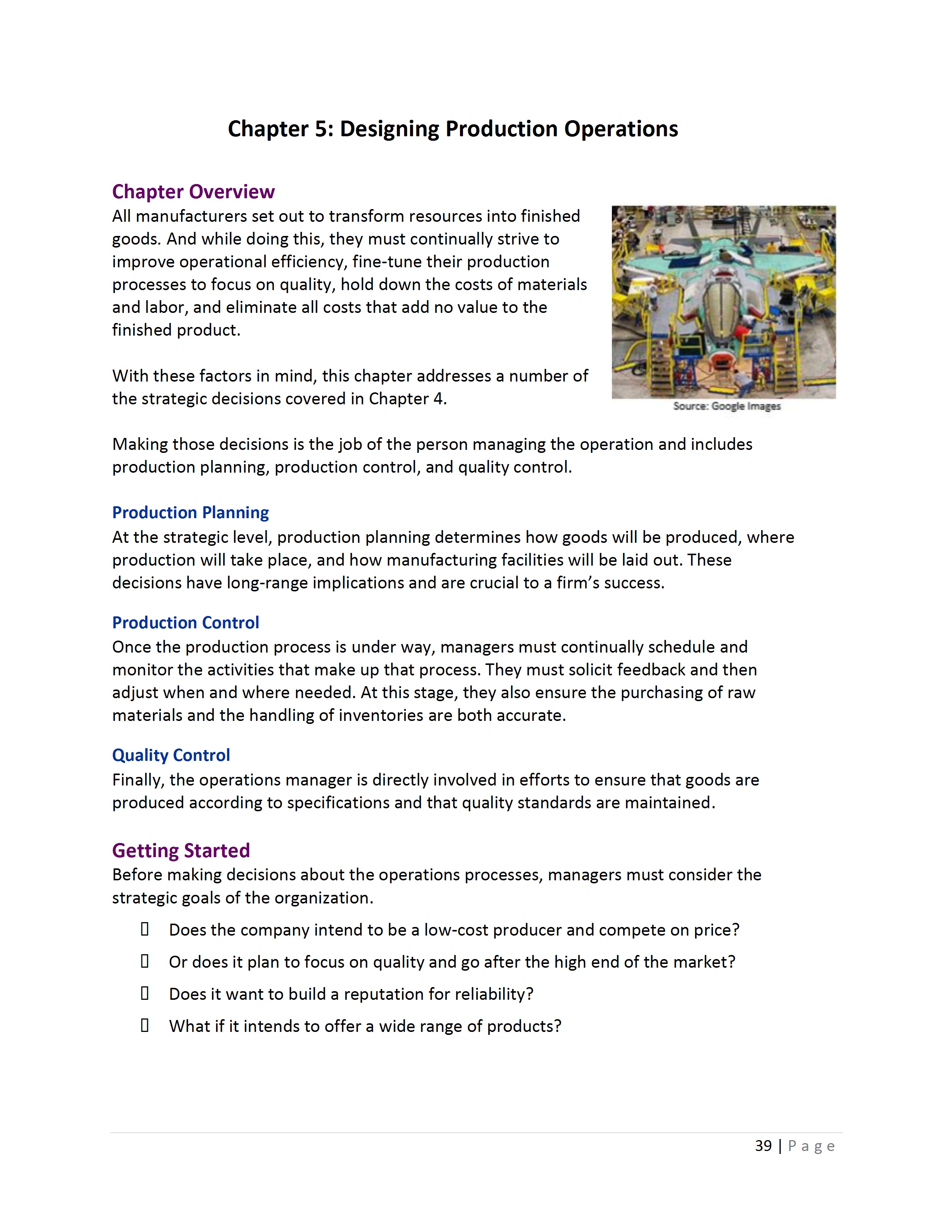

Get step-by-step solutions from verified subject matter experts