Question: A liquid mixture containing 18.3%CS2 and 81.7%CCl4 is to be separated into an overhead product containing 89%CS2 and a bottom product of 96.5%CCl4 (all weight

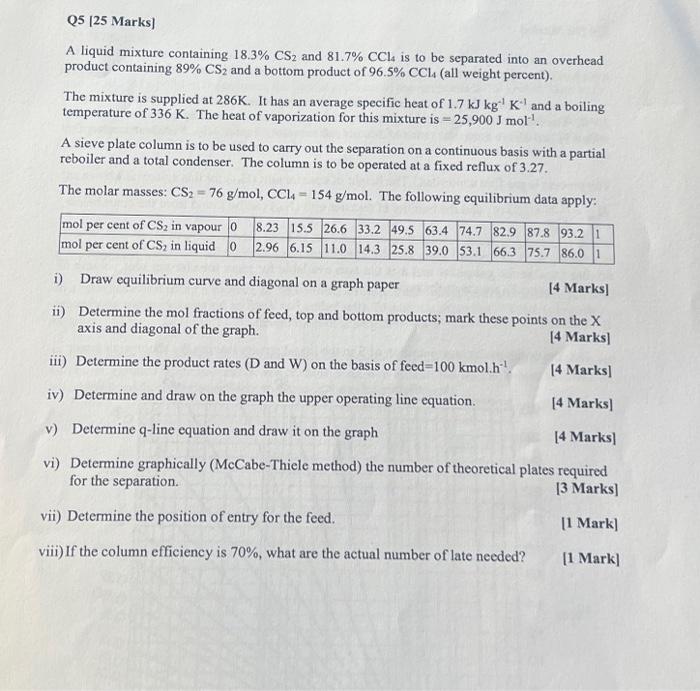

A liquid mixture containing 18.3%CS2 and 81.7%CCl4 is to be separated into an overhead product containing 89%CS2 and a bottom product of 96.5%CCl4 (all weight percent). The mixture is supplied at 286K. It has an average specific heat of 1.7kJkg1K1 and a boiling temperature of 336K. The heat of vaporization for this mixture is =25,900Jmol1. A sieve plate column is to be used to carry out the separation on a continuous basis with a partial reboiler and a total condenser. The column is to be operated at a fixed reflux of 3.27. The molar masses: CS2=76g/mol1CCl4=154g/mol. The following equilibrium data apply: i) Draw equilibrium curve and diagonal on a graph paper [4 Marks] ii) Determine the mol fractions of feed, top and bottom products; mark these points on the X axis and diagonal of the graph. [4 Marks] iii) Determine the product rates ( D and W ) on the basis of feed =100kmolh1. [4 Marks] iv) Determine and draw on the graph the upper operating line equation. [4 Marks] v) Determine q-line equation and draw it on the graph [4 Marks] vi) Determine graphically (McCabe-Thiele method) the number of theoretical plates required for the separation. [3 Marks] vii) Determine the position of entry for the feed. [1 Mark] viii) If the column efficiency is 70%, what are the actual number of late needed? [1 Mark]

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts