Question: A local engineering shop is responsible for producing small metal items (e.g. washers, inserts and spacers) for the hardware industry to supply with nuts

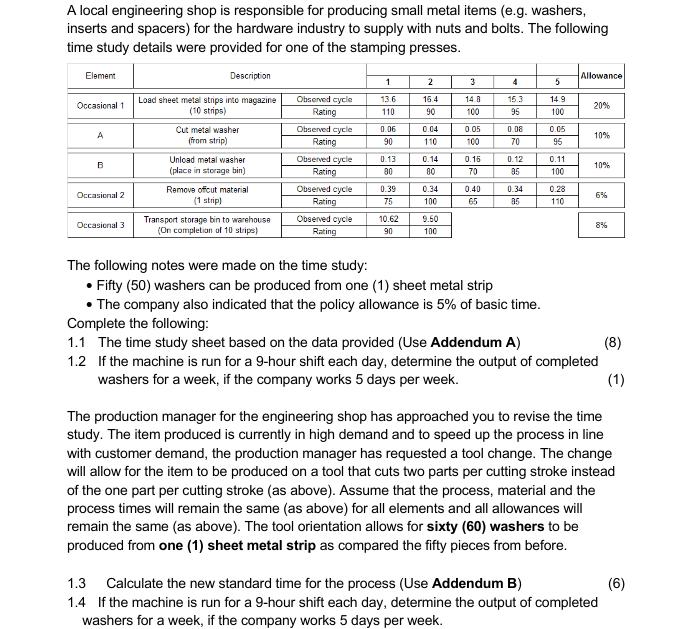

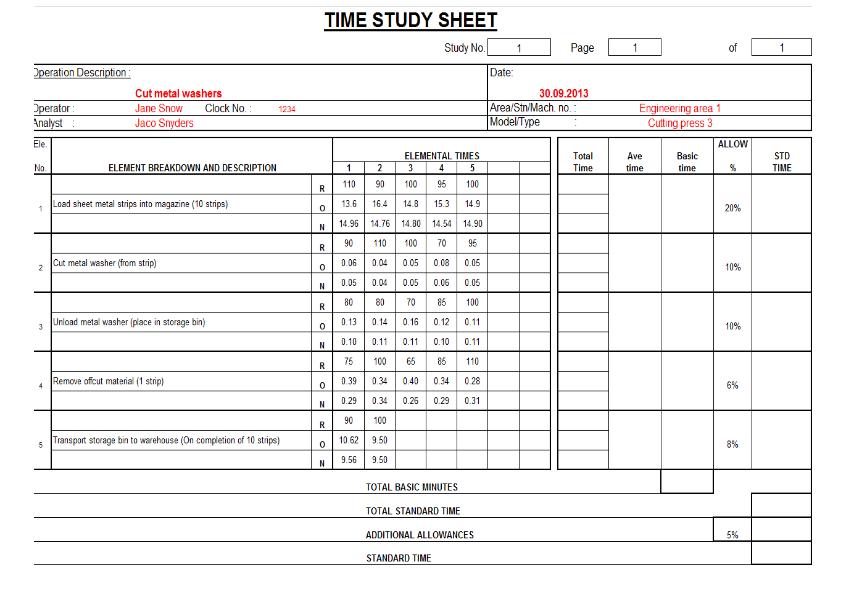

A local engineering shop is responsible for producing small metal items (e.g. washers, inserts and spacers) for the hardware industry to supply with nuts and bolts. The following time study details were provided for one of the stamping presses. Element Occasional 1 A B Occasional 2 Occasional 3 Description Load sheet metal strips into magazine (10 strips) Cut metal washer (from strip) Unload metal washer (place in storage bin) Remove offcut material (1 strip) Transport storage bin to warehouse (On completion of 10 strips) Observed cycle Rating Observed cycle Rating Observed cycle Rating Observed cycle Rating Observed cycle Rating 1 13.6 110 0.06 90 0.13 80 0.39 75 10.62 90 2 16.4 90 0.04 110 0.14 80 0.34 100 9.50 100 3 14.8 100 0.05 100 0.16 70 0.40 65 4 15.3 95 0.08 70 85 0.12 0.34 85 The following notes were made on the time study: Fifty (50) washers can be produced from one (1) sheet metal strip The company also indicated that the policy allowance is 5% of basic time. Complete the following: 1.1 The time study sheet based on the data provided (Use Addendum A) 5 14.9 100 0.05 95 0.11 100 0.28 110 Allowance 20% 10% 10% 6% 8% 1.2 If the machine is run for a 9-hour shift each day, determine the output of completed washers for a week, if the company works 5 days per week. (8) 1.3 Calculate the new standard time for the process (Use Addendum B) 1.4 If the machine is run for a 9-hour shift each day, determine the output of completed washers for a week, if the company works 5 days per week. (1) The production manager for the engineering shop has approached you to revise the time study. The item produced is currently in high demand and to speed up the process in line with customer demand, the production manager has requested a tool change. The change will allow for the item to be produced on a tool that cuts two parts per cutting stroke instead of the one part per cutting stroke (as above). Assume that the process, material and the process times will remain the same (as above) for all elements and all allowances will remain the same (as above). The tool orientation allows for sixty (60) washers to be produced from one (1) sheet metal strip as compared the fifty pieces from before. (6) Operation Description: Operator Analyst S Ele. No. 2 3 5 Cut metal washers Jane Snow Jaco Snyders ELEMENT BREAKDOWN AND DESCRIPTION Clock No. Load sheet metal strips into magazine (10 strips) Cut metal washer (from strip) Unload metal washer (place in storage bin) Remove offcut material (1 strip) 1234 Transport storage bin to warehouse (On completion of 10 strips) TIME STUDY SHEET Study No. R 0 N R 0 N R 0 N R 20 O 0 N R 0 N ELEMENTAL TIMES 4 5 3 100 95 100 13.6 16.4 14.8 15.3 14.9 14.95 14.76 14.80 14.54 14.90 90 110 100 70 95 0.06 0.04 0.05 0.08 0.05 0.05 0.04 0.05 0.06 0.05 80 80 70 85 100 0.13 0.14 0.16 0.12 0.11 0.10 0.11 0.11 0.10 0.11 75 100 65 85 110 0.39 0.34 0.34 0.28 0.29 0.34 0.25 0.29 0.31 90 100 9.50 9.50 1 110 10.62 9.56 2 90 | 0.40 TOTAL BASIC MINUTES TOTAL STANDARD TIME ADDITIONAL ALLOWANCES STANDARD TIME Date: 1 Page 30.09.2013 Area/Stn/Mach. no.: Model Type Total Time 1 Engineering area 1 Cutting press 3 Ave time Basic time of ALLOW 96 20% 10% 10% 6% 28 5% STD TIME

Step by Step Solution

3.53 Rating (153 Votes )

There are 3 Steps involved in it

Addendum A Standard Time Sheet based on original data Element Description Basic Time Rating Factor S... View full answer

Get step-by-step solutions from verified subject matter experts