Question: A manufacturing system has gained a new long-term contract to manufacture several components which may form two different part families. The contract term is 10

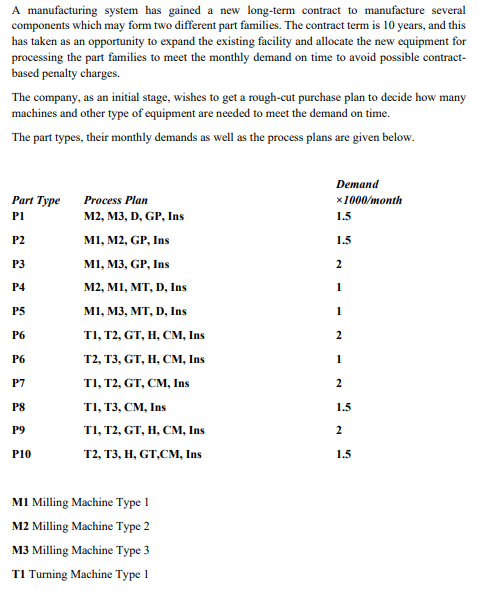

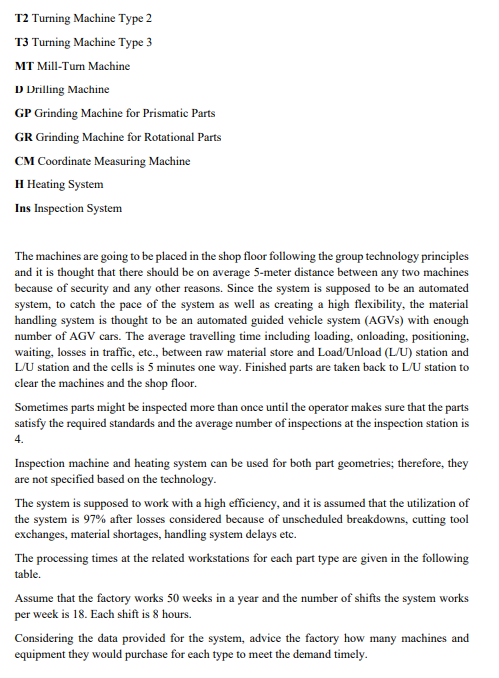

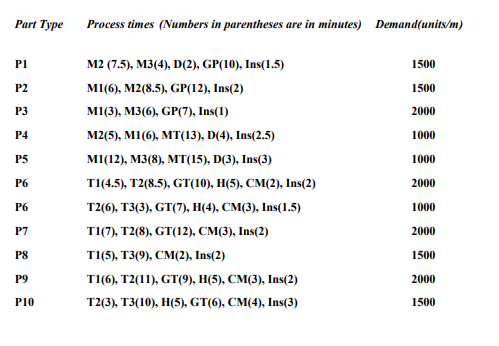

A manufacturing system has gained a new long-term contract to manufacture several components which may form two different part families. The contract term is 10 years, and this has taken as an opportunity to expand the existing facility and allocate the new equipment for processing the part families to meet the monthly demand on time to avoid possible contractbased penalty charges. The company, as an initial stage, wishes to get a rough-cut purchase plan to decide how many machines and other type of equipment are needed to meet the demand on time. The part types, their monthly demands as well as the process plans are given below. M1 Milling Machine Type 1 M2 Milling Machine Type 2 M3 Milling Machine Type 3 T1 Turning Machine Type 1 T2 Turning Machine Type 2 T3 Turning Machine Type 3 MT Mill-Turn Machine D Drilling Machine GP Grinding Machine for Prismatic Parts GR Grinding Machine for Rotational Parts CM Coordinate Measuring Machine H Heating System Ins Inspection System The machines are going to be placed in the shop floor following the group technology principles and it is thought that there should be on average 5-meter distance between any two machines because of security and any other reasons. Since the system is supposed to be an automated system, to catch the pace of the system as well as creating a high flexibility, the material handling system is thought to be an automated guided vehicle system (AGVs) with enough number of AGV cars. The average travelling time including loading, onloading, positioning, waiting, losses in traffic, etc., between raw material store and Load/Unload (L/U) station and L/U station and the cells is 5 minutes one way. Finished parts are taken back to L/U station to clear the machines and the shop floor. Sometimes parts might be inspected more than once until the operator makes sure that the parts satisfy the required standards and the average number of inspections at the inspection station is 4. Inspection machine and heating system can be used for both part geometries; therefore, they are not specified based on the technology. The system is supposed to work with a high efficiency, and it is assumed that the utilization of the system is 97% after losses considered because of unscheduled breakdowns, cutting tool exchanges, material shortages, handling system delays etc. The processing times at the related workstations for each part type are given in the following table. Assume that the factory works 50 weeks in a year and the number of shifts the system works per week is 18 . Each shift is 8 hours. Part Type Process times (Numbers in parentheses are in minutes) Demand(units/m) \begin{tabular}{lll} P1 & M2 (7.5), M3(4), D(2), GP(10), Ins(1.5) & 1500 \\ P2 & M1(6), M2(8.5), GP(12), Ins(2) & 1500 \\ P3 & M1(3), M3(6), GP(7), Ins(1) & 2000 \\ P4 & M2(5), M1(6), MT(13), D(4), Ins(2.5) & 1000 \\ P5 & M1(12), M3(8), MT(15), D(3), Ins(3) & 1000 \\ P6 & T1(4.5), T2(8.5), GT(10), H(5), CM(2), Ins(2) & 2000 \\ P6 & T2(6), T3(3), GT(7), H(4), CM(3), Ins(1.5) & 1000 \\ P7 & T1(7), T2(8), GT(12), CM(3), Ins(2) & 2000 \\ P8 & T1(5), T3(9), CM(2), Ins(2) & 1500 \\ P9 & T1(6), T2(11), GT(9), H(5), CM(3), Ins(2) & 2000 \\ P10 & T2(3), T3(10), H(5), GT(6), CM(4), Ins(3) & 1500 \end{tabular}

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts