Question: (a) Name and explain TWO (2) possible defects/problems that can happen during the sheet metal working process. (b) One of the solutions for the

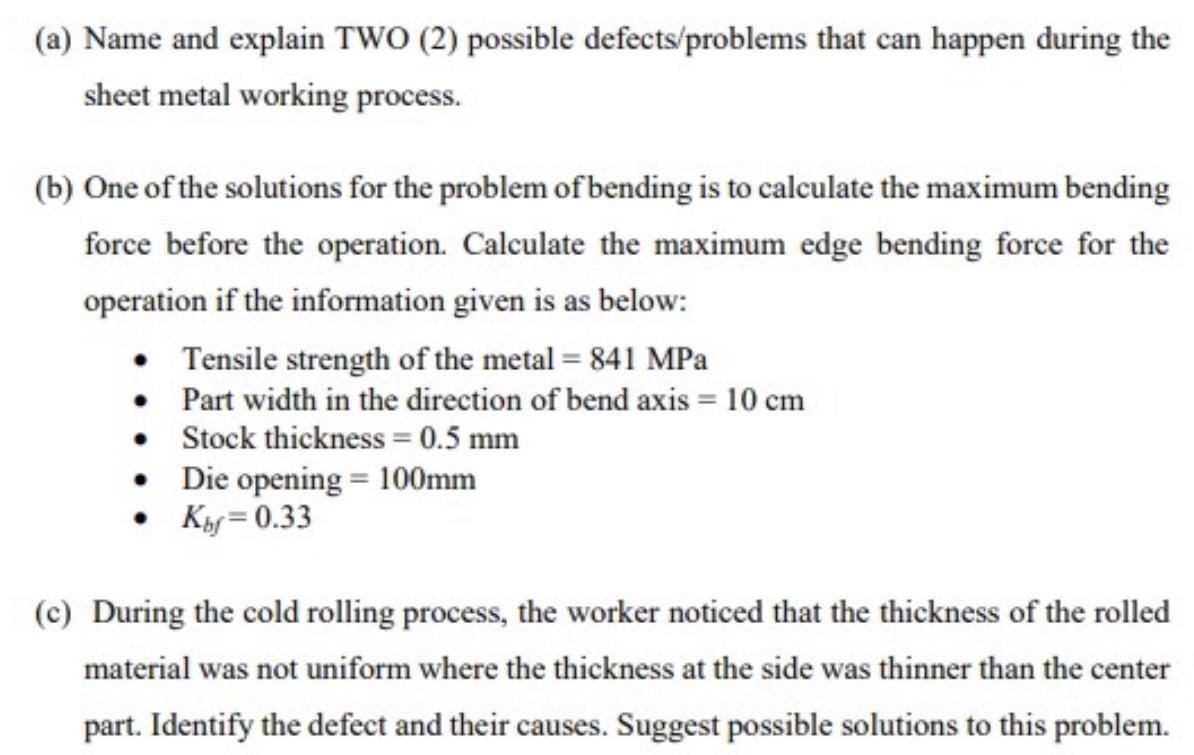

(a) Name and explain TWO (2) possible defects/problems that can happen during the sheet metal working process. (b) One of the solutions for the problem of bending is to calculate the maximum bending force before the operation. Calculate the maximum edge bending force for the operation if the information given is as below: Tensile strength of the metal = 841 MPa Part width in the direction of bend axis = 10 cm Stock thickness = 0.5 mm Die opening 100mm Kur=0.33 (c) During the cold rolling process, the worker noticed that the thickness of the rolled material was not uniform where the thickness at the side was thinner than the center part. Identify the defect and their causes. Suggest possible solutions to this problem.

Step by Step Solution

There are 3 Steps involved in it

The image shows a question divided into three parts a b and c which pertain to defectsproblems in sheet metal working bending force calculations and issues in the cold rolling process respectively I w... View full answer

Get step-by-step solutions from verified subject matter experts