Question: A nickel titanium alloy is used to make components for jet turbine aircraft engines. Cracking is a potentially serious problem in the final part because

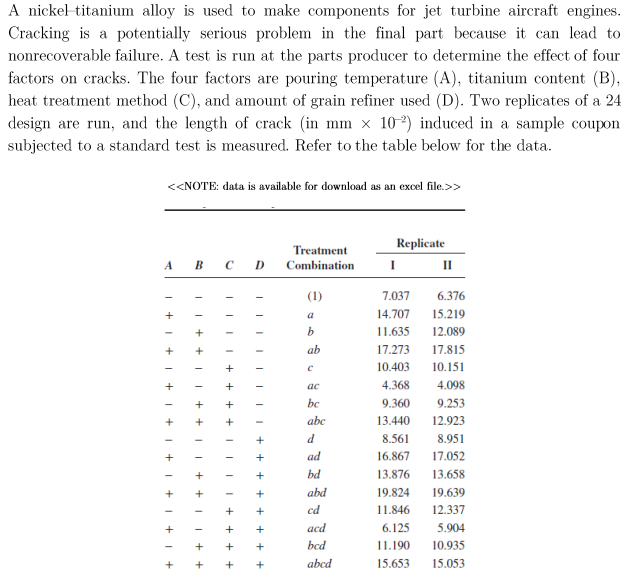

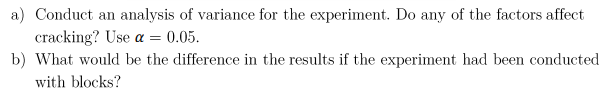

A nickel titanium alloy is used to make components for jet turbine aircraft engines. Cracking is a potentially serious problem in the final part because it can lead to nonrecoverable failure. A test is run at the parts producer to determine the effect of four factors on cracks. The four factors are pouring temperature (A), titanium content (B), heat treatment method (C), and amount of grain refiner used (D). Two replicates of a 24 design are run, and the length of crack (in mm x 10 ?) induced in a sample coupon subjected to a standard test is measured. Refer to the table below for the data. > Treatment Replicate A BCD Combination I II (1) 7.037 6.376 a 14.707 15.219 h 11.635 12.089 ab 17.273 17.815 - C 10.403 10.151 - ac 4.368 4.098 + bc 9.360 9.253 abc 13.440 12.923 + d 8.561 8.951 ad 16.867 17.052 bd 13.876 13.658 abd 19.824 19.639 ed 11.846 12.337 L acd 6.125 5.904 bed 11.190 10.935 abcd 15.653 15.053e} Conduct an analysis cf variance fer the experiment. Dc any ef the factcre affect cracking? Use a = {105. b} What would be the difference in the results if the experiment had been conducted with blocks

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts