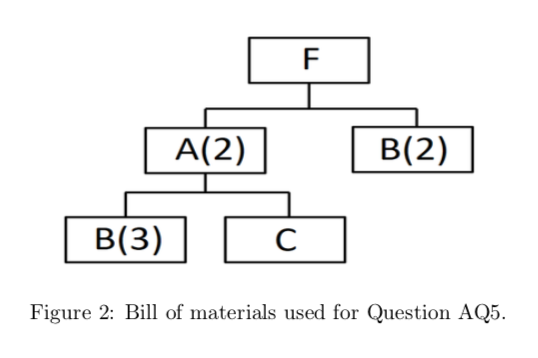

Question: A Orm uses components A, B, and C to assemble a Onal product iFi; see the bill of materials in Figure 2. 1. [5 marks]

A Orm uses components A, B, and C to assemble a Onal product iFi; see the bill of materials in Figure 2.

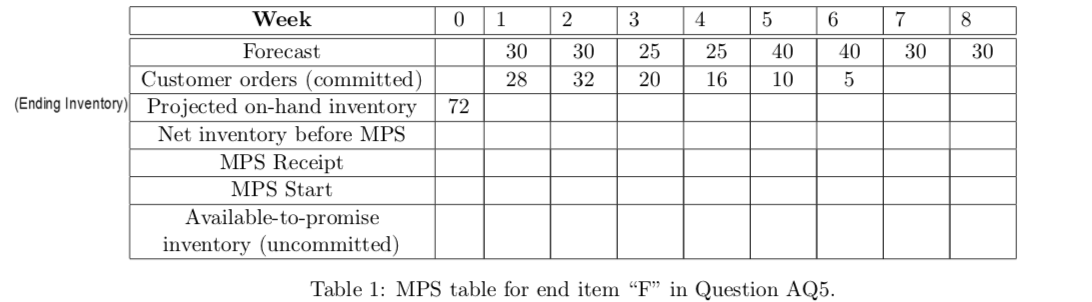

1. [5 marks] You are required to Oll in Table 1 to prepare a master schedule for product iF.iEach time when the Orm assembles the product, the Orm always uses the Oxed lot size rule to make 50 units of iF.iThe Ormis assembly time for product iFiis 1 week. The beginning inventory for iFiis 72 units; the forecast and promised customer orders for this end item are provided in Table 1.

-

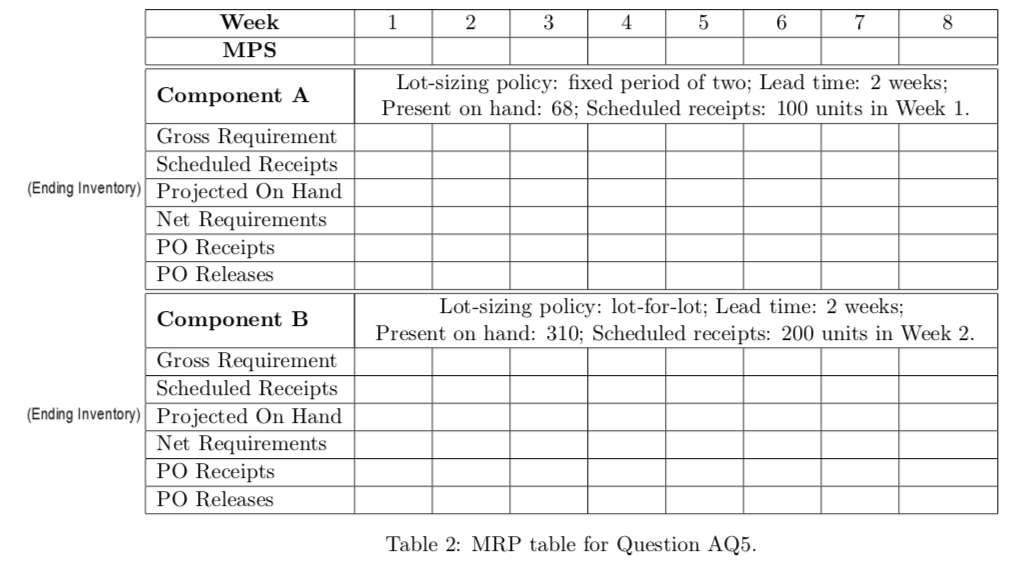

[8 marks] Use your master schedule in Table 1 to develop material requirements plans (MRPs) for components A and B. Note that you are required to Onish the MRP tableo i.e., Table 2 on page 7o in which you can Ond the present on-hand quantity (i.e., the beginning inventory), lead time, lot-size policy, and scheduled receipts for each of components A and B.

-

[3 marks] Calculate the total inventory cost for the end item F during the eight weeks. Note that, for each week, the inventory cost includes a Oxed ordering cost and a holding cost. We assume that the per order Oxed ordering cost is $200/order, and the unit holding cost is $1 per item per week. The Oxed cost is incurred each time when the Orm places an order. The holding cost is calculated according to the number of remaining items at the end of each week.

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts