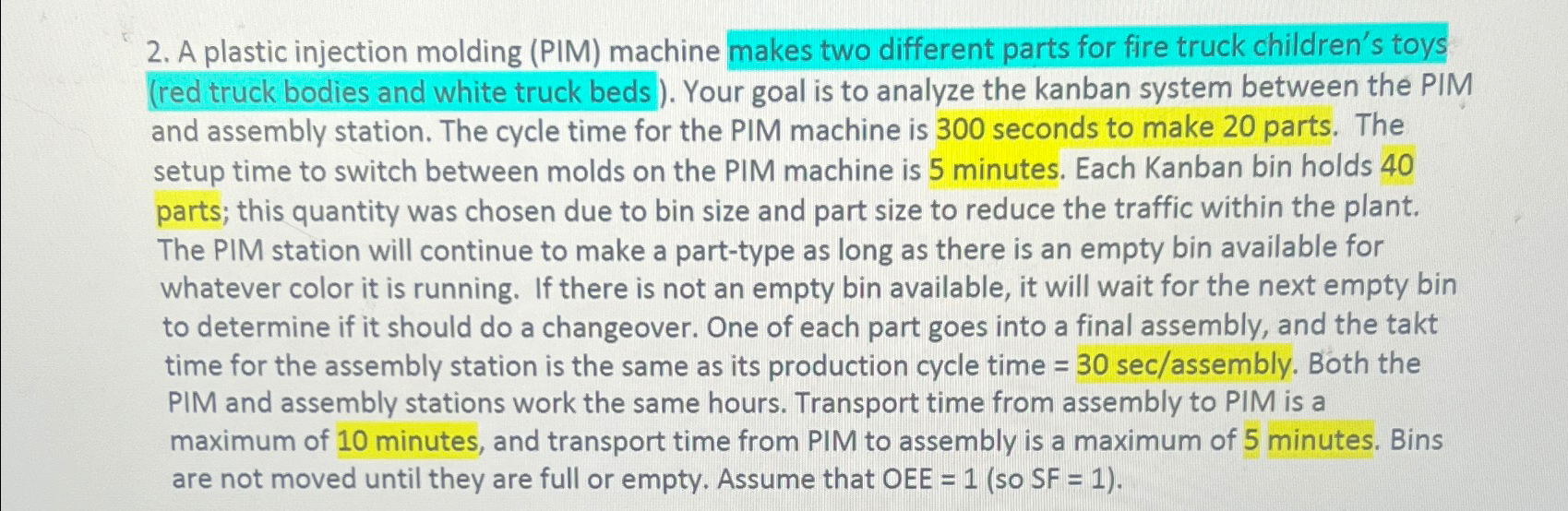

Question: A plastic injection molding ( PIM ) machine makes two different parts for fire truck children's toys ( red truck bodies and white truck beds

A plastic injection molding PIM machine makes two different parts for fire truck children's toys red truck bodies and white truck beds Your goal is to analyze the kanban system between the PIM and assembly station. The cycle time for the PIM machine is seconds to make parts. The setup time to switch between molds on the PIM machine is minutes. Each Kanban bin holds parts; this quantity was chosen due to bin size and part size to reduce the traffic within the plant. The PIM station will continue to make a parttype as long as there is an empty bin available for whatever color it is running. If there is not an empty bin available, it will wait for the next empty bin to determine if it should do a changeover. One of each part goes into a final assembly, and the takt time for the assembly station is the same as its production cycle time assembly. Both the PIM and assembly stations work the same hours. Transport time from assembly to PIM is a maximum of minutes, and transport time from PIM to assembly is a maximum of minutes. Bins are not moved until they are full or empty. Assume that OEE so SF

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock