Question: please read the case study and answer questions 1-9 and write a brief summary of the case study CASE V Automotive Headlamps II: The Paradigm

please read the case study and answer questions 1-9 and write a brief summary of the case study

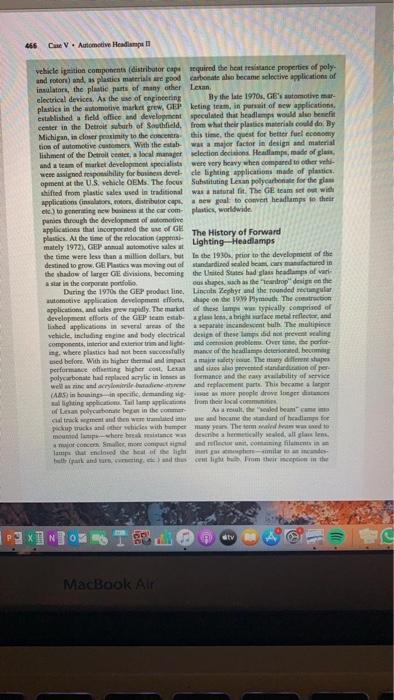

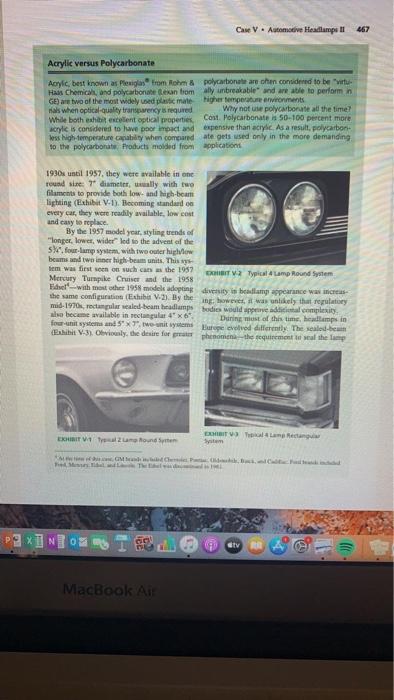

CASE V Automotive Headlamps II: The Paradigm Shift from Standardized Glass Sealed Beams to Today's Plastic Custom Designs Overview bases and radio cabinets) and, in 1930, formed the company's first plastics department to mar This case brings together factor ket these plastic materials in the general market Strategic business unit management to other manufacturers of similar devices philosophy Plastic materials with improved physical Innovation in the face of contrary men properties were a continuously evolving need as tional wisdom" more complex component designs demanded How innovation can be viewed differently improved physical material properties General by various stakeholder Electric Research and Development Laboratories, Customer organizational as well as product one of the premier industry sponsored R&D goals centers, maintained an ongoing materials arch Values perceived by the customer, rather cont. This led GE cach labs to the develop thun the supplier ment of new, thermoplastic engineering plas ties such as pelarbonate (Lexan) in 1959 Introduction and Company polyphenylene oxide (PPO) in 1965, and PPO Backgrounds alloys (Nory) by 1966. With these materih For clarity, the backgrounds of the main players to become GE chairman became a significant GEP, then led by Jack Welch who was call in this case are provided factor in the proving plastic material industry General Electric da star in the compte portfolio The General Electric Lamp Divici (GEL) The two Mrategic business unit (BU) of is nowth of the very beginning of Ede General Electric directly involved in this case ing back to the company founding by Thomas are the General Electrie Panties Division and Edwon in 1878. Over the years, Globe the General Electric Lamp Division the forcing developments in me The General Electric Company Plastics every market Madium lighting in and air Division (CEP) began as an internal supplier of poet lighting system. home lighting, une thermoset phenolie molding Compounds fowind incary loopnandescent in electrical components such as cum tentang ham, mer Thermosets and Thermoplastics Sed that he Enging the that dergo a chemical change can be the modo heated in the monoces and Ponudwald when do not. There are theng.com Lapable of wounding ones with to web premalo paxil NT 3 I 40 MacBook Air Case V Automoth Headlampe 465 upor, sodium, unde GEL integrated steel mills, rubber plantations, the plans high-volume producer and is among the only planta (windows, windshield---not lighting). lighting device manufactures that make ment of iron ore here and mines, and paint man is own glaw for la products turing facilities. Ford, like GM, manufactured The glass scaled beam automotive head many of its own components including lighting lamp, introduced in the 1930s, is one of the devices and was strongly vertically integrated developments that GEL is most prod. At the in the manufacture of components made of time of this case, GEL was the largest supplier plastic. However, Ford did not manufacture of light bulbs to the North American autom headlamps and thus was the largest customer tive market. The sealed-beam design had ofGEL remained an industry standard from the 1930s to the date of this come within the corporate Regulatory Agencies structure, GEL was a significant canh The US Department of Transportation (DOT and its component National Highway Trafie General Motors Safety Administratie (NHTSA) were respon General Motors (GM), the largest automotive sible for maintaining safety standards for the company in the world, at the time of this case, industry DOT performance standardi regulated held almost 60 percent of the American Windshields, window lighting effectiveness market. GM was built primarily through occupant protection devices integratie acquisition of not only smaller car companies and on the vehicles but supplier companies and brands as well AC Spark Plugs and Delce electrical compo. Professional Organizations nents were among GM-owned throughout The Society of Automotive Engiem SAE) sition, supply divisions. The GM Guide Lamp the profesionality of automotive and Division (GMOideo to be confused with sportation cacines. As the auto industry GEL) produced anos Tump assemblies for evered the SAE. Ex with many profesional the interior and exterior of GM products, imated voluntary peormance GMCuide was also the primary supplier of dance for any vir le systems and devices sealed beam headlamps to GM vehicles, Many SAB recommended performance though they were not as integrated as GEL dards became and in practice, DOT adapted many of these voluntary standards Ford Motor Company regulations Ford Motor Company was the second largest tome company in the world with approx GEP Organization maily 35 percent of the Americ market. The GP initially served the industry growth of und wachieved primarily tightrom de Cleveland cheiden vertical interiore than oquisition. At tally theme of GEL ay pics one time fond dan pested GET"plastic deduses the pool WC SOM VC MacBook Air 466 CV Automotive Headlamps 11 vehicle ignition components distributor cape required the heat resistance properties of poly. and rotor) and, as plastics matrials we good about also became selective application of insulators, the plastic parts of many other Lexan. electrical devices. As the we of engineering By the late 1970s. GB's stomotive plastics in the wtomotive market grew, GEP keting team, in part of sew application, established field office and development speculated that headlamps would we benefit center in the Detroit suburb of Southed, from what their plastic materials could do y Michigan, in der pensimity to the con sis time, the quest for better fuel economy tion of automotive customers. With the estab was a major factor in design and material lishment of the Detroit center, a local manant lection decisions Headlamps, made of glass, and a team of market development specialista were very heavy when compared to other were assigned responsibility for barnen develde lighting applications made of plastic opment at the U.S. vehicle OEMs. The focus Substituting Lexan polycarbonate for the plan shifted from plastie sales used in traditional was satural it. The team set out with applications (soos distributor caps new goal to convert headlamps to their el) tog new business at the car com- plastics, worldwide panies through the development of automotive applications that incorporated the woGE plastics. At the time of the relocation Coppens The History of Forward mately 1972). GEPtal comotive sales Lighting Headlamps the time were less than a million dollars, but in the 1930, prior to the development of the destined to grow, GE Pass was moving out of standardized sealed by manufactured in the shadow of larger Edision, becoming the United States had glass heaps of val star in the corpore portfolio cases, has the strop design the During the 1970 the GEP product line, Lincoln Zephyr and the rounded regular automotive application development efforts, shape on 1919 Pyme Theron applications, and sales propidly. The market the lawwe typically comprised of development efforts of the GEP em tablet, ahirace me reflector and lished applications in eas of the a separate and cont hals The moltiple vehicle, including engine and body clectrical design of these langs id not preventing components, Interior and extend under problem. O, the perfor ing, where plastic had been successfully maaf the headlamps detected, bem wed before. With its higher thermal and impact amoy The different super performance of higher coll Leandres i provenind and oper polycarbonate had replaced acrylic informance and the ability of service laptomirtual and replacement parts. This became a larger As in homini pecite, demanding ople gece ad lighting application. Tullam applicatiom their com oftesa petoele in the comme As the lead beam.com chat truck met de wema un bocu da standard of Trade pickup trucks and there with more. The term wird wedi mumewhere in describe helly Bealed all planeten major concert decit coming film lampe che ho the light the mode 3x] No com o sity MacBook Air Case V. Automotive Headlamps It 467 Acrylic versus Polycarbonate Acryl, best known as Plexiglas from Rom & polycarbonate are han considered to be Hans Chemical and polycarbonate Lean biomaly unbreakable and are able to perform GE) are two of the most widely used imate Higher temperature environments Hals when optical quality transparency required Why not use polycarbonate all the time? While both what extent optical properties Cont. Polycarbonate 50-100 percent more crylic is considered to be poor impact ad expensive than acrylic. As a result, polycarbon less high temperature capability when compared ate gets used only in the more demanding to the polycarbonate Products molded from application 1930s until 1957, they were wailable in one road size: 7 diameter, wally with two filaments to provide both low- and Nigh-bear lighting (Exhibit V.1. Becoming standard every car, they were readily available, low cost and cany to replace By the 1957 model year, styling trends of "longer, lower, wider led to the advent of the sk.four-lamp system with two other high beams and two inner high beam units. This sys tem was first seen on such as the 1957 KOT V Typical Lamp Round System Mercury Tumpike Cruise and the 1958 del with most the 1958 modele adopting diversity is balam perance was incas- the same configuration (Exhib V.2 By the ing, however, likely that regulatory mid-1976, rectangular wald-beam badlamps bodies would appeneditional complexity became wailable in rectangular 4"x6" During most of this time, headlamps in fournit ystems and Twentystems are evolved differently the sealed-beam Exit V-3). Obviously, the desire for greater shenomenathe requiremental the lamp Malang Rectangu HIIT Trond CMC 3xl N 03 mg tv MacBook Air 468 CV. Aan Head II free potentially damaging and/or che vehicles had evolved to all plate unit, elements-over he major actor. Instead, designed to fit the style and shape of the car, headlamps continued to evolve dagen designed wing replaceable, stated the need from to the vehicle design and contro con the mor of the lump, and standard sockets and wed to evolvedov. Typical were connections. Acryl plastics were typically comprised of a glam lems, a metal reflect and wied for lases, with various other plastics and one or more replaceable but with an industry metal competing for the elector housing standardized connection at the of the hand trim components Rulls evolved frowe standard incandescent to halogen cycle units, typically complified by the The Situation A two-filament high or low-ban design in the main headlamps, with smile filament bulbs When GEP begin to approach a comunits used for long-range driving from other with the idea of plastic headlamps, they forward lighting applications. These designetered many objections. Some of those objec were a ball within a buithe halogen tilations were that plastic headlamps wouldn't mentinell was fully and separately enclated work home within its own glassevelope, which was the protected within the leadphoning. However, compared toga sledbenihy will be able to maintain a hermosal, the designs did not meet U.S. mandards, though they were considered more stylish and. thus causing prematurellement failure with fuel economy becoming more (note that this was to be an in erodynas. Furopean vehicles sold in the only when it within bulb we United States required to comply with DOT standards had the desire modified to incorpo the lens face will be find rate the US sealed-beam is to the re to wathering and have detriment of the vehicle price the life of the chick In the late 1970s, the destination by the eneringe not legal or met conventional incandescent scaled beam in approved by the US Department of the United States waged by the desire Transport the NHTSA, are they ended by the SAE for belter lighting and the wailability of they will cow more and therefore Furopean halogen-bob replacement units the whermarket the consumer replacement income to change and retrofit market. As a HM devel some car company captveram aped heading with halogen ble det divai M Guide Division Inside of the standard shaped plass scaled an independent supplies that make beam beatamping in a premium range hadde opendects, producing a white brighter lipe ble in ested in in (the halogen filament was cacapsulated Clwaldham lamp sepatutely and sealed within the headlamp The they will be hul within ab recepten At this juncture with the exception of At this time, GEL hadap leerlingen odernem ifall factors could become These 33 0 Atv MacBook Air Case V.Atom Headlamps 469 Captive and Custom Molders A manufacture that makes plastics components component we produced to the redacturer at its own pic manufacturing faci specifications by custom injection moldes ud tooteinfacluring contract providers that produce plast parts torties that produce plastic parts strictly for deligned and speed by the manufacture that manufacturer. When outre, plastic the styled headlamp wafat. that wouldn't be The Lexan lump would be significantly universally adopted by the industry lighter than a los realed-beam lamp. Faced with these objections, a few mem contributing to need for lower vehicle bers of the CEP marketing ttum felt that the project was net worth puring. The impot These benefits, when combined into marketing the plastic headlamp could be better meaning applications with easier to overcome different and have that wantage over their spent a les complex applications really poskupe. could provide a method for menu facturers to make the can look better and and fer objectioni). Sollte IP Der buite in plastie Bedings, and a few people prodottiglie des. Indeed, this time tam wanted to move forward and develop comes potentially reduce collision were prepared to better care it there was a brightened concern for safety, since The Marketing Plan apate of rational rear-end collision and resulties had occured coincidentally. In Benefits ad to the way aspects. Pote the GET marketing people bega naling and proped shared to the crush design developing out the benefit of the websful comes being modynamic and the contributing helps to OEM'. They concluded that the primary of plastics were concept was ukly taped shearlie ham Ford and the term www the hility to rigut design with during developed application) optical detail production thun le low vide mere design meer modern lined innend, with the help The development was with rated le shape and both forum GP med the Mall fons GMG Am commik ang short span -earthen OM OMGuide www.ant evitally really this by and contemplatically the tharmam pal chas to be became The office was reduced with compared to the beach within and The Plan when by the bad wide " V MacBook Air Joseph Gigliorano - Business to Business Marketing-Pearson (2010).pdf (page 505 of 547) 470 CV Automove Hedium II of GIL GEL home office e Cleveland on the vehicle. If headlamps were to be made of Fortunately. GEP management the plastic, Fond could manufacture the housing Pittsfield, MA, heders hacked the efforts till purchasing just the film bulb within of the GLP Detroit team and provide political bulb) from outside ore. Additionally, support within for them Ford was know more receptive to innov- tive ideas, particularly from marketing Finding the Right Customer perspective as it understood the role innovation The GEP approach to the customer then played in a better product and image in the changed. Realizing that the poi come market. These factors combined to lead the within the customer were cially those who GEP em to focus on Ford as the most likely would value the benefits of styling different company to innova ties, they focused on the design and styling The GEP team developed champion of the car companies well a within the organisation an open-minded. managers in product planning and marketing in creative manager in advanced placering other words, attention centered in the people who not only got it but wanted to see it the car companies who were responsible for the happen himself. Though the effort was cond way act looked and sold. The degree to which wed to be a waste of time by some Beed person these stakeholder marketing, saying design del particularly in regard to the previously and product planning department within the mentioned megy as the datapre The company buying center could infleurd the Generato the other members fengineering and purchasing make the new happen people became cmical Wile engineering Challenging the Standard way. If sometimes reluctantly they did not determine vehicle content. Ale GEP markepple are so politely but approaching all car manufacture, the way to sumption GEP marketing te realised MwamThey some important diverses. Most airly flest customer because GMGuide ww every well the location design focused on consommation. Throw be clock Howeve GM designers, particularly at Cadillac hal Sylvania preto say exped interest in the plasti da prove this was there. The applicable help, they would not be able to take on SA standard wax is place primarily design tage of the development GMGuide was pee to describe the ally to the holy The Indipen wwaaa Font webcam amputing Fond did not man dengan head was purchasing mo GEP e decided to the Teal needs from CEL Fan whowever, Hally when the stated in the main of plate GEDOT lattestatis waitings DC ingae ON 1 ] 2 I ELV MacBook Air Case V. Automotive Headlampe 471 a meeting to discuss safe headlamp idea coating, bonded to an injection molded, metal At this meeting, the official indicated that the lined, and couted reflector housing. The vehicle government's only real concern was that application was the inboard lamp of the four headlights provided the driver consistent, sade lamp rectangular system (high beam only, llumination over the period of its life for that part of the standard foorlamp configuration) of the car) and should one fail, replacements units on the 1980 Lincoln Town Car, of which be widely available. In fact, they did not care approximately 60.000 examples were produced about their material or shape. The GEP repre- and told that year. Conventional glass scaled- sentative cited the safety benefits of the plastic beam units were used on the outer highlow concept. The plastic und halogen bulb combil beam pair of headlamps. This configuration mation would reduce the risk of fire is provided way to gain production and end collision---since the Lexan was virtually experience and prove the durability of the breakable and even if broken, the bulb fila plastie lamp in actual field e. (Should the new ment was separately encapsulated. Therefore plastic lamps fail, the vehicle would still have the risk of fire was reduced, compared to the the normal safe use of the primary outer glass sealed-beam unit, with its incandescent "highw"scaled beam, and the Inbound plastic filament exposed when the glass housing was high beam could be carily retrofitted with the broken standard glaslamp.) The plastic lumps were manufactured by GEL part of a development Validating the Concept project funded by GEP and Ford The best application on the Lincoln Town GEP decided to make some prototype plastic Car was deemed culpaving the way for headlamps, test them in smalled us to see if further as they would work over an acceptable period of GEP Wired experienced automotive time. Since GEL was the lighting expert and designet/stylist they don't like to be called this point, they did not want to get too far from Mys) from Europe where aerodynamic the project at least to maintain knowledge of headlamps, made of plass, styled to fill the car what was going on, they agreed to work with were the form The designer developed here God Ford to develop the prototypes. All and illustri af existing and pole agreed that if those is wat well, then the talvthicle models, graphically sharing the it we would be a further prove with prope of mone, flush production vehicle trial Lil the ene plastic designed to the right hal que le providing tangholes in the otherwise si find Prototypes were designed faticated and convertidas e worked tested. Results were file and reviewed Athout this time. Lamp with with Ford as well as with the appropriate son of the develop program. To say agencia Pond decided to further validate the both on GEP continuidade GEL be an unden. While care them. The first par policies at the manufacture of plastic ham bot US with the last de white-piimties in the wind that the stuplich des com bean designing a hacer en with GET albit light want the Fond virgen models with an email the new Fun SY MacBook Air Joseph Giglierano - Business to Business Marketing-Pearson (2010).pdf (page 507 472 Case V. Automotive Headlamps II go ahead with the strodynamic lamp develop Questions for Discussion ment. It preferred to partner with GE, as GE had both plastic materials and lighting exper- 1. What is your assessment of the situation? 2 What are the benefits of plastic headlamps tise. However, it wouldn't refrain from finding To whom another lighting manufacturer and/or another plastic material supplier and put them together 3. How would you overcome the objections into a team (e. a value network) to make of the GM Guide Lamp division the project happen. The vice president of Ford 4. What is the rationale behind the GEL asked the GEP representative to get that decision to withdraw support from the message back to GE development? 5. Does it make sense to innovate the offer Analysis ings of a cash cow? Why? 6. How has GEL impacted the GEP rela- This case represents a situation that is often tionship at Ford associated with incrvation. A few people within 7. What approaches would you take with a company have a bright idea that would benefit other potential customers them if accepted and implemented. However, 8. How would you address and overcome the current industry situation is characterized by the issues regarding agency approval a well-established technology and committed 7. What are the key factors likely to deter manufacturing, combined with external, thund mine success in this application? putty government and industry standards devel oped around the incumbent systems tv MacBook Air