Question: A small caf owner feels that the average daily demand for its best-seller item in inventory for the coming year is 720 units. The

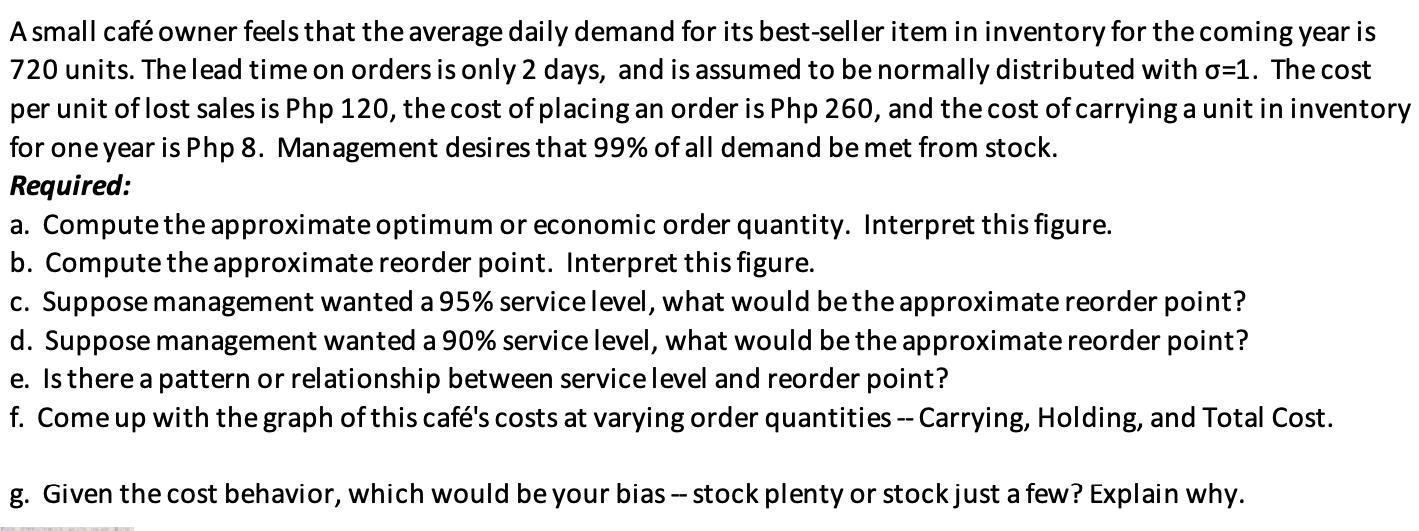

A small caf owner feels that the average daily demand for its best-seller item in inventory for the coming year is 720 units. The lead time on orders is only 2 days, and is assumed to be normally distributed with o=1. The cost per unit of lost sales is Php 120, the cost of placing an order is Php 260, and the cost of carrying a unit in inventory for one year is Php 8. Management desires that 99% of all demand be met from stock. Required: a. Compute the approximate optimum or economic order quantity. Interpret this figure. b. Compute the approximate reorder point. Interpret this figure. c. Suppose management wanted a 95% service level, what would be the approximate reorder point? d. Suppose management wanted a 90% service level, what would be the approximate reorder point? e. Is there a pattern or relationship between service level and reorder point? f. Come up with the graph of this caf's costs at varying order quantities -- Carrying, Holding, and Total Cost. g. Given the cost behavior, which would be your bias -- stock plenty or stock just a few? Explain why.

Step by Step Solution

3.42 Rating (165 Votes )

There are 3 Steps involved in it

To solve the inventory management problem we can use the Economic Order Quantity EOQ model Lets calculate the values based on the given information Average daily demand D 720 units Lead time LT 2 days ... View full answer

Get step-by-step solutions from verified subject matter experts