Question: A truncation error has occurred in a critical situation, causing extensive damage and loss of life. who is liable, if anyone? the designer of the

A truncation error has occurred in a critical situation, causing extensive damage and loss of life. who is liable, if anyone? the designer of the hardware? the designer of the software? the programmer who actually wrote that part of the program? the person who decided to use the software in that particular application? what if the software had been corrected by the company that originally developed it, but that update had not been purchased and applied in the critical application? what if the software had been pirated?

read the case and answer the following questions which are given above:

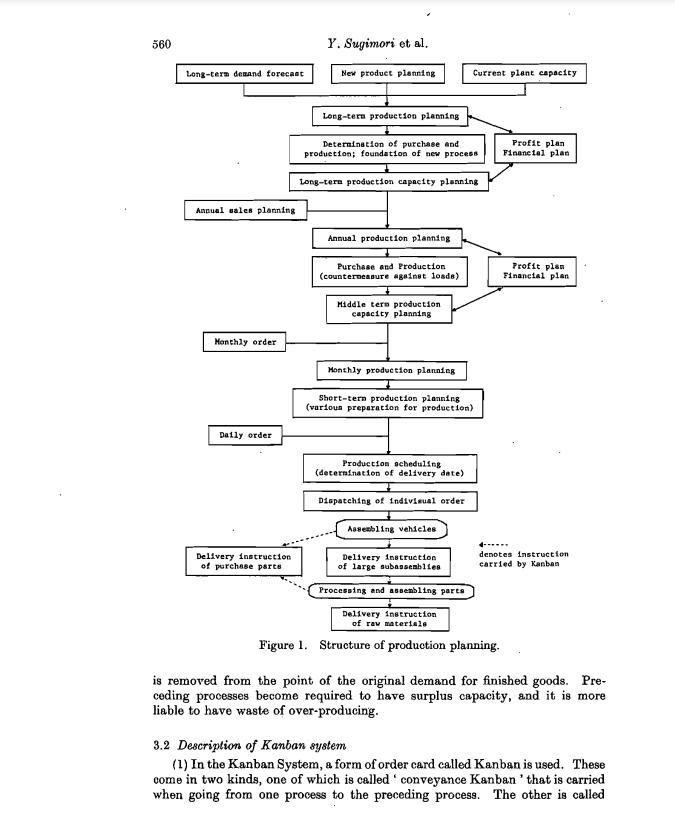

Toyota production system and Kanban system Materialization of just-in-time and respect-for-human system Y. SUGIMORI, K. KUSUNOKIt, F. CHO+ and S. UCHIKAWA+ The Toyota Production System and Kanban System introduced in this paper was developed by the Vice-President of Toyota Motor Company, Mr. Taiichi Ohno, and it was under his guidance that these unique production systems have become deeply rooted in Toyota Motor Company in the past 20 years. There are two major distinctive features in these systems. One of these is the 'just-in-time production', s specially important factor in an assembly industry such as automotive manufacturing. In this type of production, "only the necessary products, at the necessary time, in necessary quantity" are manufactured, and in addition, the stock on hand is held down to a minimum. Second, the system is the respect-for-human' system where the workers are allowed to display in full their capabilities through active participation in running and improving their own workshops. Starting point of concept-making the most of Japanese characteristics The starting point of the concept of the Toyota Production System was in the recognition of Japan's distinguishing features. The most distinctive feature of Japan is the lack of natural resources, which makes it necessary to import vast amounts of materials including food. Japan is placed under a disadvantageous condition in terms of a cost of raw material when compared to the European and American countries. To overcome this handicap, it is essential for the Japanese industries to put forth their best efforts in order to produce better quality goods having higher added value and at an even lower production cost than those of the other countries. This was the first thing that Toyota recognized. The second distinctive feature is that Japanese concept of work, such as consciousness and attitude, differed from that held by the European and American workers. The Japanese traits include: (1) group consciousness, sense of equality, desire to improve, and diligence born from a long history of a homogeneous race; (2) high degree of ability resulting from higher education brought by desire to improve; (3) centring their daily living around work. Such Japanese traits have also been reflected in the enterprises. Customs such as (1) lifetime employment system, (2) labour unions by companies, (3) little discrimination between shop workers and white-collar staff, and (4) chances available to workers for promotion to managerial positions, have been of great service in promoting the feeling of unity between the company and workers. Also, unlike European countries, Japan does not have the problem of foreign workers. Therefore from the standpoint of labour environment, Japan is much better off than the European and American countries. In order to make full use of the Japanese advantages, it is important that the Presented at the 4th International Conference on Production Research (Tokyo) August 1977. +Production Control Department, Toyota Motor Co., Ltd. 1 Toyota-cho Toyota- shi 471 Japan. Published by Taylor & Francis Ltd, 10-14 Macklin Street, London WC2B 5NF.

Step by Step Solution

3.38 Rating (167 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts