Question: A - Whilst drilling (8 3/8) section, at depth (9600 ft) a well kick was detected and the well was shut-in. Drilling supervisor instructed the

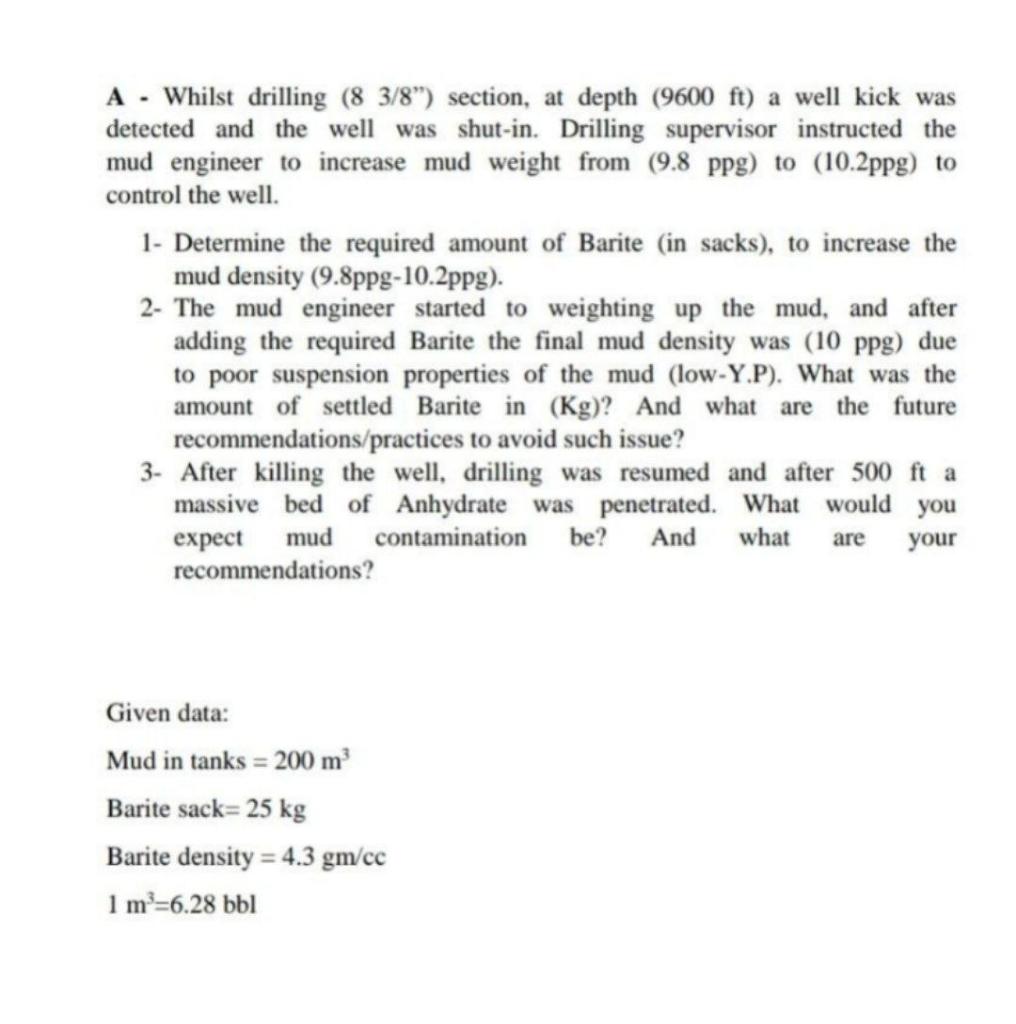

A - Whilst drilling (8 3/8) section, at depth (9600 ft) a well kick was detected and the well was shut-in. Drilling supervisor instructed the mud engineer to increase mud weight from (9.8 ppg) to (10.2ppg) to control the well. 1- Determine the required amount of Barite (in sacks), to increase the mud density (9.8ppg-10.2ppg). 2- The mud engineer started to weighting up the mud, and after adding the required Barite the final mud density was (10 ppg) due to poor suspension properties of the mud (low-Y.P). What was the amount of settled Barite in (Kg)? And what are the future recommendations/practices to avoid such issue? 3- After killing the well, drilling was resumed and after 500 ft a massive bed of Anhydrate was penetrated. What would you expect contamination be? And your recommendations? mud what are Given data: Mud in tanks = 200 m Barite sack= 25 kg Barite density = 4.3 gm/cc 1 m=6.28 bbl

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts