Question: a) Your manufacturing process requires to drill a 300 mm deep hole with a diameter of 30.0 mm on titanium alloy workpiece. Propose a

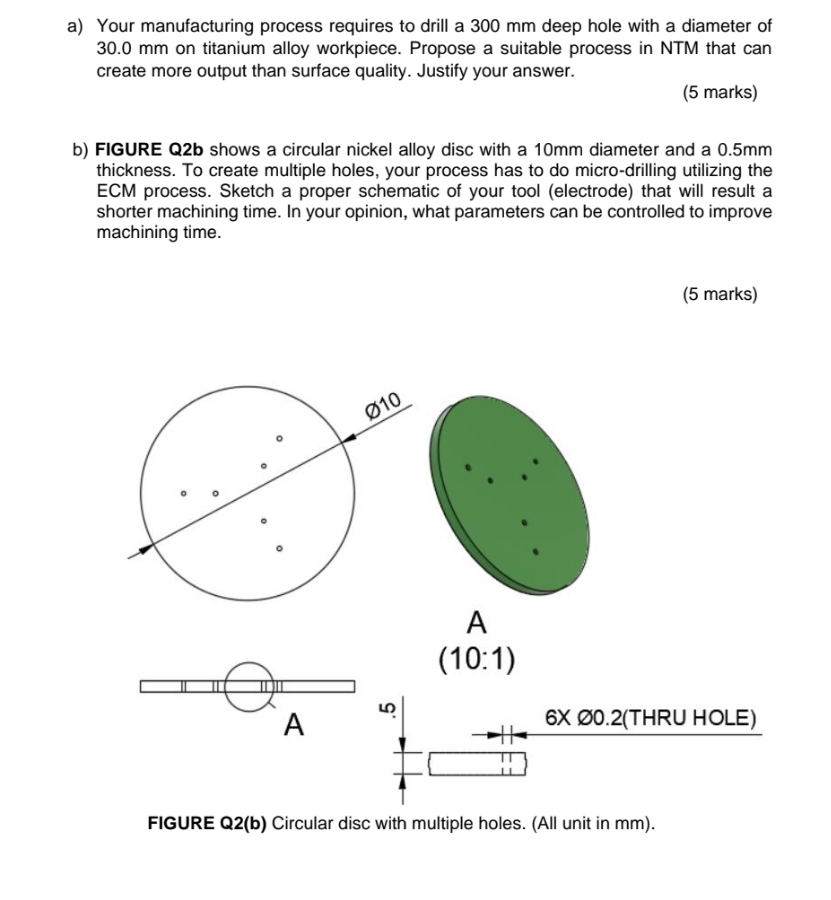

a) Your manufacturing process requires to drill a 300 mm deep hole with a diameter of 30.0 mm on titanium alloy workpiece. Propose a suitable process in NTM that can create more output than surface quality. Justify your answer. (5 marks) b) FIGURE Q2b shows a circular nickel alloy disc with a 10mm diameter and a 0.5mm thickness. To create multiple holes, your process has to do micro-drilling utilizing the ECM process. Sketch a proper schematic of your tool (electrode) that will result a shorter machining time. In your opinion, what parameters can be controlled to improve machining time. A .5 010 A (10:1) 6X 00.2(THRU HOLE) FIGURE Q2(b) Circular disc with multiple holes. (All unit in mm). (5 marks)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts