Question: ABC was a medium - sized Hong Kong - based company with two manufacturing plants in China, one in Dongguan and the other in Shanghai

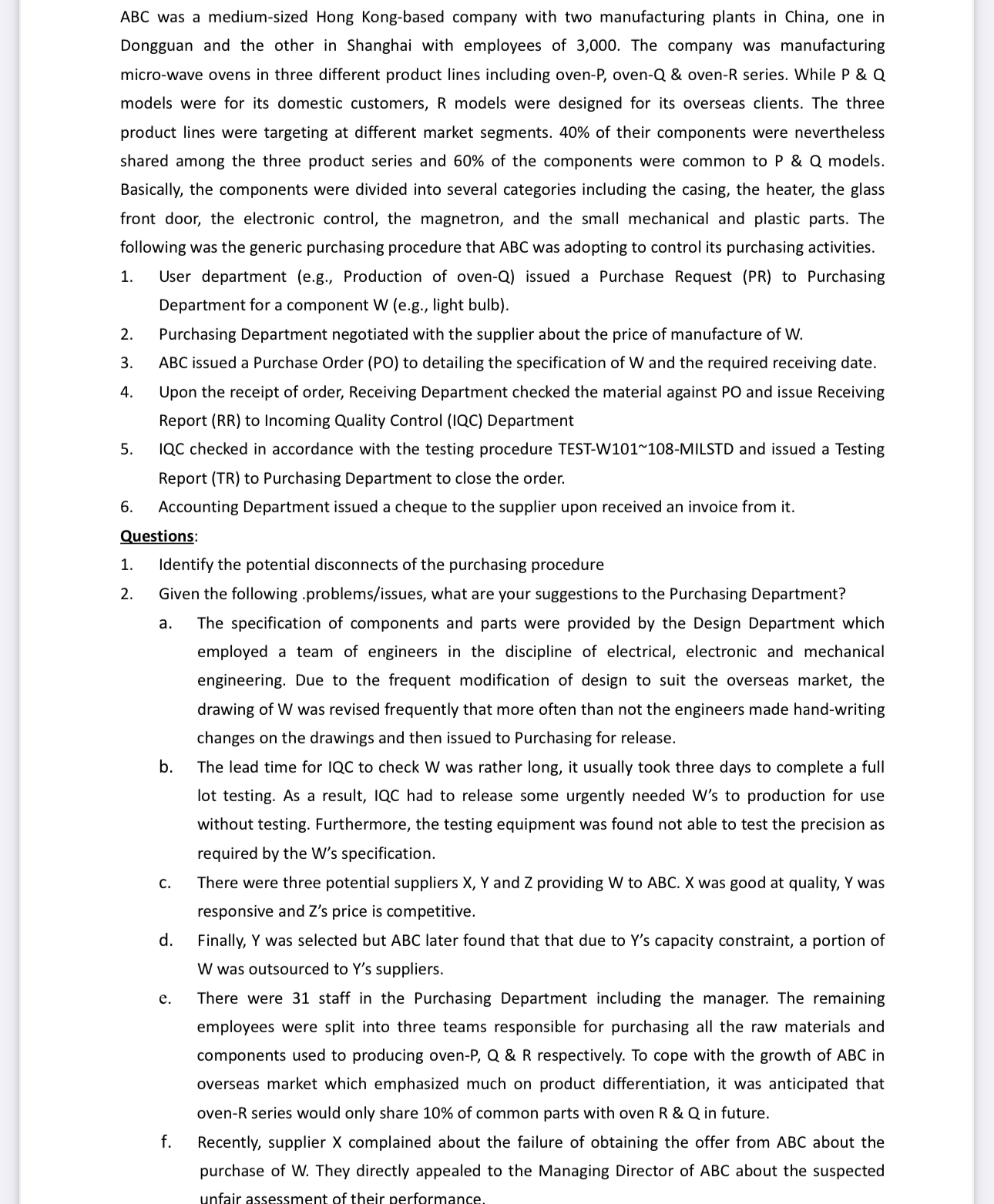

ABC was a mediumsized Hong Kongbased company with two manufacturing plants in China, one in Dongguan and the other in Shanghai with employees of The company was manufacturing microwave ovens in three different product lines including oven oven & ovenR series. While & models were for its domestic customers, models were designed for its overseas clients. The three product lines were targeting at different market segments. of their components were nevertheless shared among the three product series and of the components were common to P & Q models. Basically, the components were divided into several categories including the casing, the heater, the glass front door, the electronic control, the magnetron, and the small mechanical and plastic parts. The following was the generic purchasing procedure that ABC was adopting to control its purchasing activities.

User department eg Production of ovenQ issued a Purchase Request PR to Purchasing Department for a component W eg light bulb

Purchasing Department negotiated with the supplier about the price of manufacture of

ABC issued a Purchase Order PO to detailing the specification of and the required receiving date.

Upon the receipt of order, Receiving Department checked the material against PO and issue Receiving Report RR to Incoming Quality Control IQC Department

IQC checked in accordance with the testing procedure TESTWMILSTD and issued a Testing Report TR to Purchasing Department to close the order.

Accounting Department issued a cheque to the supplier upon received an invoice from it

Questions:

Identify the potential disconnects of the purchasing procedure

Given the following problemsissues what are your suggestions to the Purchasing Department?

a The specification of components and parts were provided by the Design Department which employed a team of engineers in the discipline of electrical, electronic and mechanical engineering. Due to the frequent modification of design to suit the overseas market, the drawing of was revised frequently that more often than not the engineers made handwriting changes on the drawings and then issued to Purchasing for release.

b The lead time for IQC to check W was rather long, it usually took three days to complete a full lot testing. As a result, IQC had to release some urgently needed Ws to production for use without testing. Furthermore, the testing equipment was found not able to test the precision as required by the Ws specification.

c There were three potential suppliers and providing to ABC. was good at quality, was responsive and Zs price is competitive.

d Finally, was selected but ABC later found that that due to Ys capacity constraint, a portion of W was outsourced to Ys suppliers.

e There were staff in the Purchasing Department including the manager. The remaining employees were split into three teams responsible for purchasing all the raw materials and components used to producing ovenP Q & R respectively. To cope with the growth of ABC in overseas market which emphasized much on product differentiation, it was anticipated that ovenR series would only share of common parts with oven & in future.

f Recently, supplier complained about the failure of obtaining the offer from ABC about the purchase of They directly appealed to the Managing Director of ABC about the suspected

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock