Question: According to the above case, can you help me indicate what current methodology is used for the current system, pros and cons of the system,

According to the above case, can you help me indicate what current methodology is used for the current system, pros and cons of the system, and how can we improve the system as well? The second part is: they use quantitative method or qualitative method, please elaborate it clearly. Lastly, can you suggest some useful recommendations to solve the case problem? Thank you

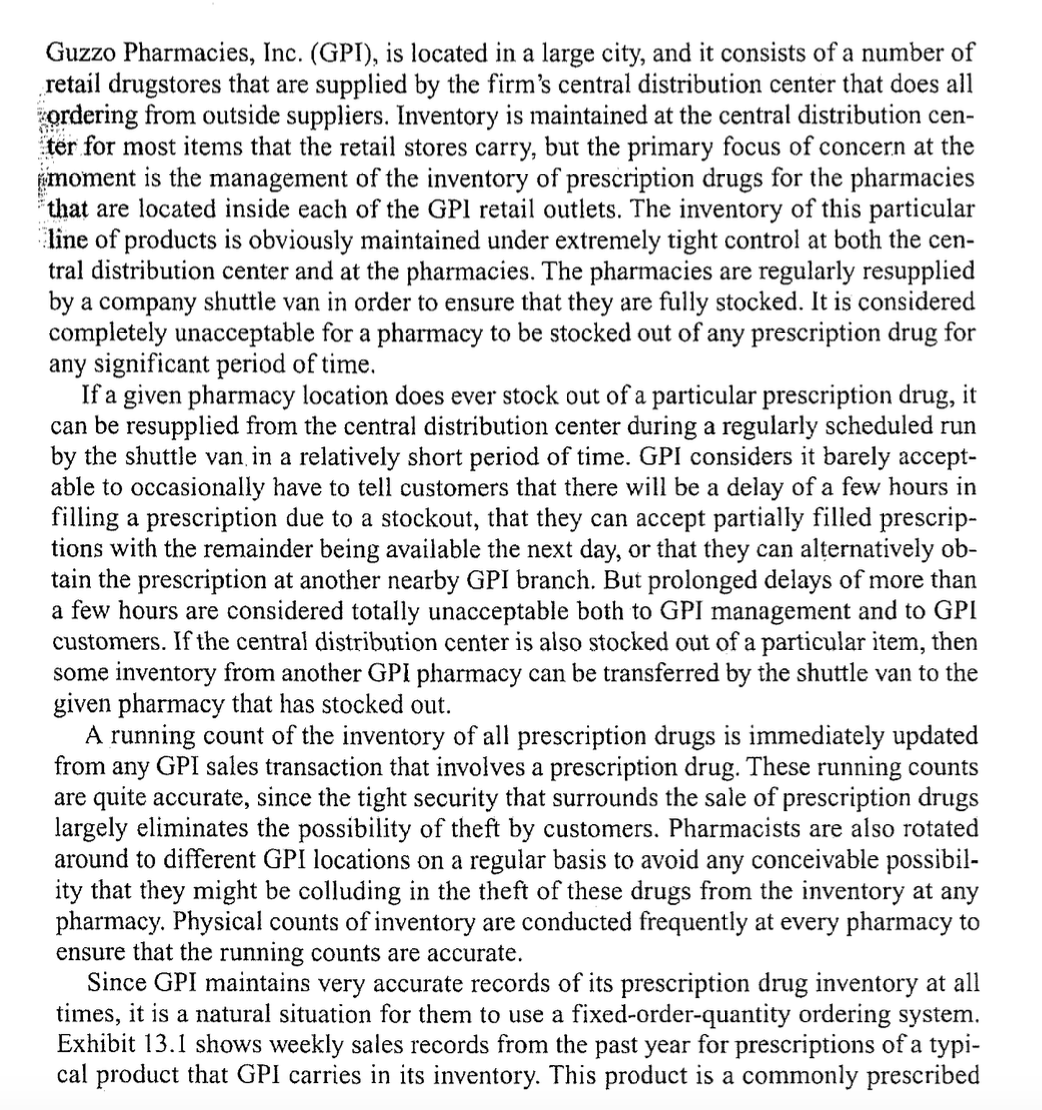

Guzzo Pharmacies, Inc. (GPI), is located in a large city, and it consists of a number of retail drugstores that are supplied by the firm's central distribution center that does all ordering from outside suppliers. Inventory is maintained at the central distribution center for most items that the retail stores carry, but the primary focus of concern at the moment is the management of the inventory of prescription drugs for the pharmacies that are located inside each of the GPI retail outlets. The inventory of this particular line of products is obviously maintained under extremely tight control at both the central distribution center and at the pharmacies. The pharmacies are regularly resupplied by a company shuttle van in order to ensure that they are fully stocked. It is considered completely unacceptable for a pharmacy to be stocked out of any prescription drug for any significant period of time. If a given pharmacy location does ever stock out of a particular prescription drug, it can be resupplied from the central distribution center during a regularly scheduled run by the shuttle van in a relatively short period of time. GPI considers it barely acceptable to occasionally have to tell customers that there will be a delay of a few hours in filling a prescription due to a stockout, that they can accept partially filled prescriptions with the remainder being available the next day, or that they can alternatively obtain the prescription at another nearby GPI branch. But prolonged delays of more than a few hours are considered totally unacceptable both to GPI management and to GPI customers. If the central distribution center is also stocked out of a particular item, then some inventory from another GPI pharmacy can be transferred by the shuttle van to the given pharmacy that has stocked out. A running count of the inventory of all prescription drugs is immediately updated from any GPI sales transaction that involves a prescription drug. These running counts are quite accurate, since the tight security that surrounds the sale of prescription drugs largely eliminates the possibility of theft by customers. Pharmacists are also rotated around to different GPI locations on a regular basis to avoid any conceivable possibility that they might be colluding in the theft of these drugs from the inventory at any pharmacy. Physical counts of inventory are conducted frequently at every pharmacy to ensure that the running counts are accurate. Since GPI maintains very accurate records of its prescription drug inventory at all times, it is a natural situation for them to use a fixed-order-quantity ordering system. Exhibit 13.1 shows weekly sales records from the past year for prescriptions of a typical product that GPI carries in its inventory. This product is a commonly prescribed 58 Part Three Supply Chain Management EXHIBIT 13.1 Weekly Sales for a Typical GPI Product steroid-based drug that is sold in most pharmacies. Each individual prescription of this particular drug is sold as a self-contained packet, and each packet contains the same number of tablets. Only one of these packets is ever sold at one time to any customer. The data in Exhibit 13.1 shows no observable patterns from seasonality or trend in the demand for this drug. GPI management wants the central distribution center to continue using a fixed-order-quantity policy for ordering prescription drug inventory from its sources. This policy should be helpful in minimizing the combined expected cost of ordering and holding inventory to account for its normal expected usage. This policy makes sense since GPI has a good estimate of existing inventory on hand for prescription drugs at all times. It is estimated that it costs about $165 to go through the process of placing and receiving an order every time an order is placed under normal circumstances, regardless of the size of the order. Since the physical volume of the product is small, shipping costs are quite small. When orders are placed under normal circumstances, the cost of the particular product in Exhibit 13.1 is $28.60 /prescription to GPI, and there is a two-week lead time for all shipments to arrive. It is possible for GPI to place emergency orders to obtain small quantities of the product in an overnight delivery, but that becomes very expensive, as we shall see later. Some accounting records have been searched to obtain information about the annual variable holding costs for prescription drugs as a percentage of the value of the item being held. This variable holding cost is primarily driven by interest GPI must pay on outstanding loans it holds to pay for buying the products it holds in inventory. The interest rate has been quite stable for the past few years, and there are other variable costs that GPI incurs from holding inventory of these prescription drugs. Last year the company spent a total of $1,896,000 on inventory-related expenses for all of their prescription drugs, not just for the selected product in Exhibit 13.1, while the associated average value of inventory being held was $5,483,000, based on the cost of product to GPI. During the previous year, $1,866,000 was spent on inventory-related expenses to hold an average value of inventory of $5,243,000. These estimates of inventory-related expenses for prescription drugs include some fixed-cost components, Part Three Supply Chain Management expected penalty costs for emergency orders. From this information, GPI management can determine the service level option with the least total annual cost. The associated cost sensitivity from shifting to other service levels can also be observed. UANTITY DISCOUNT OPTIONS GPI management has long been aware of the possibility of obtaining price breaks for ordering in large standard-shipment quantities from their suppliers. However, the amount of these discounts has not seemed adequate to consider that option since the required order quantities are quite large. For the particular product that we have been considering, a 1.5% price reduction is offered for order quantities of 3,000 units. The lead time for placing such orders would remain the same, and the option would still be open to obtain emergency overnight deliveries. GPI has sufficient demand for the product so that buying in such quantities would never lead to having the labeled expiration date reached while the product is still in inventory. There is the reduction in the unit cost for acquiring the product, and GPI does purchase the product in large amounts over the course of a year. There would also be an associated reduction in the unit holding cost. GPI management would like to see the same type of cost analysis that was performed above repeated for the situation in which the price break is offered. Policies of 90%,91%,92%,93%,94%,95%,96%,97%, 98%, and 99% service levels should be considered for this option. The results should be compared to the costs from the earlier analysis. Obviously, the total expected annual cost for these policies would now have to include the price of acquiring the product

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts