Question: To decrease labor cost, a manufacturing facility recently changed from manual milling machines to CNC milling machines for all its production. It finds that

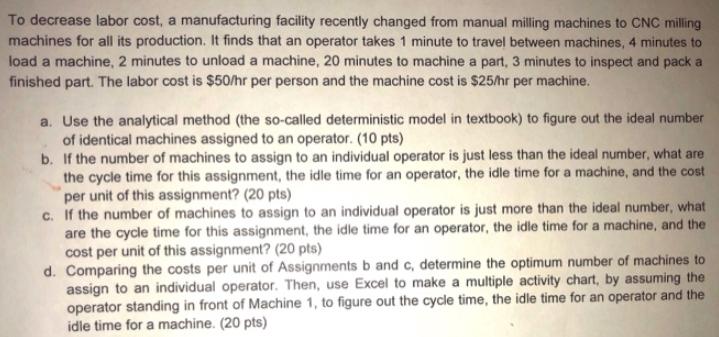

To decrease labor cost, a manufacturing facility recently changed from manual milling machines to CNC milling machines for all its production. It finds that an operator takes 1 minute to travel between machines, 4 minutes to load a machine, 2 minutes to unload a machine, 20 minutes to machine a part, 3 minutes to inspect and pack a finished part. The labor cost is $50/hr per person and the machine cost is $25/hr per machine. a. Use the analytical method (the so-called deterministic model in textbook) to figure out the ideal number of identical machines assigned to an operator. (10 pts) b. If the number of machines to assign to an individual operator is just less than the ideal number, what are the cycle time for this assignment, the idle time for an operator, the idle time for a machine, and the cost per unit of this assignment? (20 pts) c. If the number of machines to assign to an individual operator is just more than the ideal number, what are the cycle time for this assignment, the idle time for an operator, the idle time for a machine, and the cost per unit of this assignment? (20 pts) d. Comparing the costs per unit of Assignments b and c, determine the optimum number of machines to assign to an individual operator. Then, use Excel to make a multiple activity chart, by assuming the operator standing in front of Machine 1, to figure out the cycle time, the idle time for an operator and the idle time for a machine. (20 pts)

Step by Step Solution

3.53 Rating (167 Votes )

There are 3 Steps involved in it

a The ideal number of machines is 8 because this allows the operator to be in constant motion loading and unloading machines as they become available This reduces the overall time spent on each task a... View full answer

Get step-by-step solutions from verified subject matter experts