Question: Additional Problem - Increasing Lead Time: You are the production control manager at Advanced Tech Manufacturing. Queue time is currently long in your production area

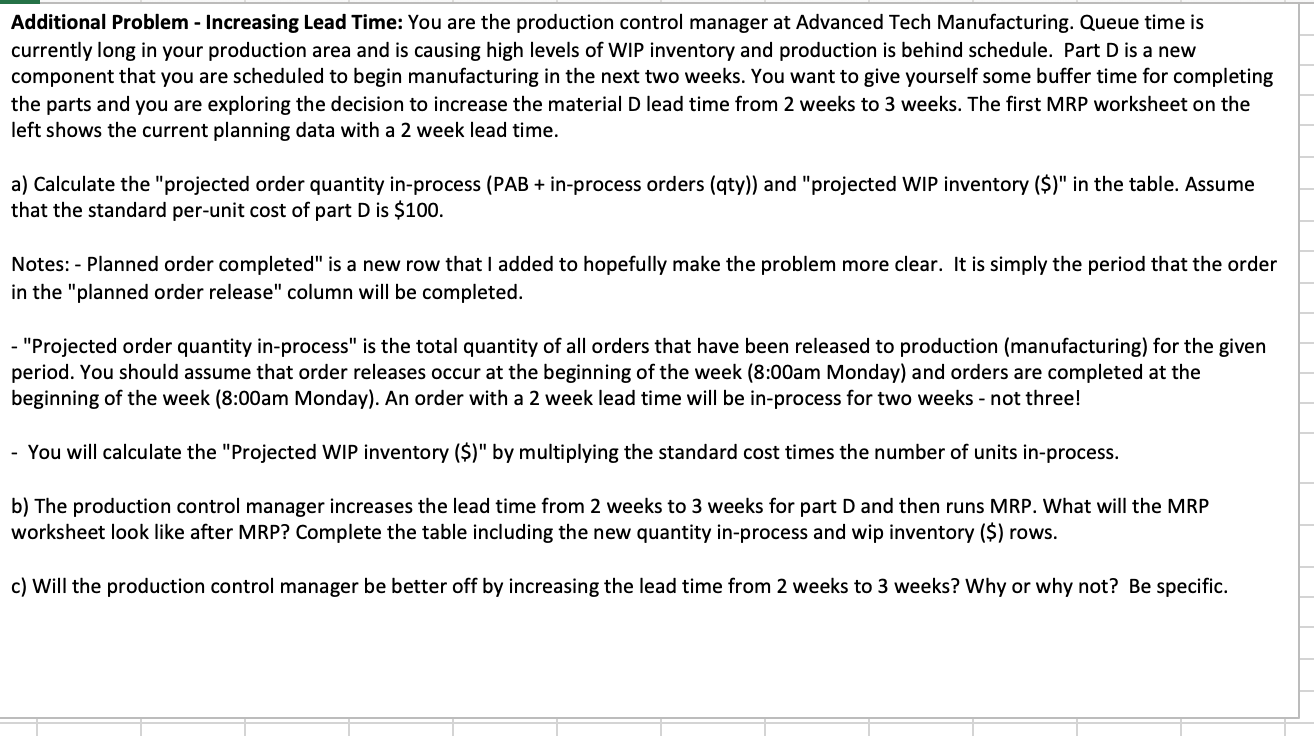

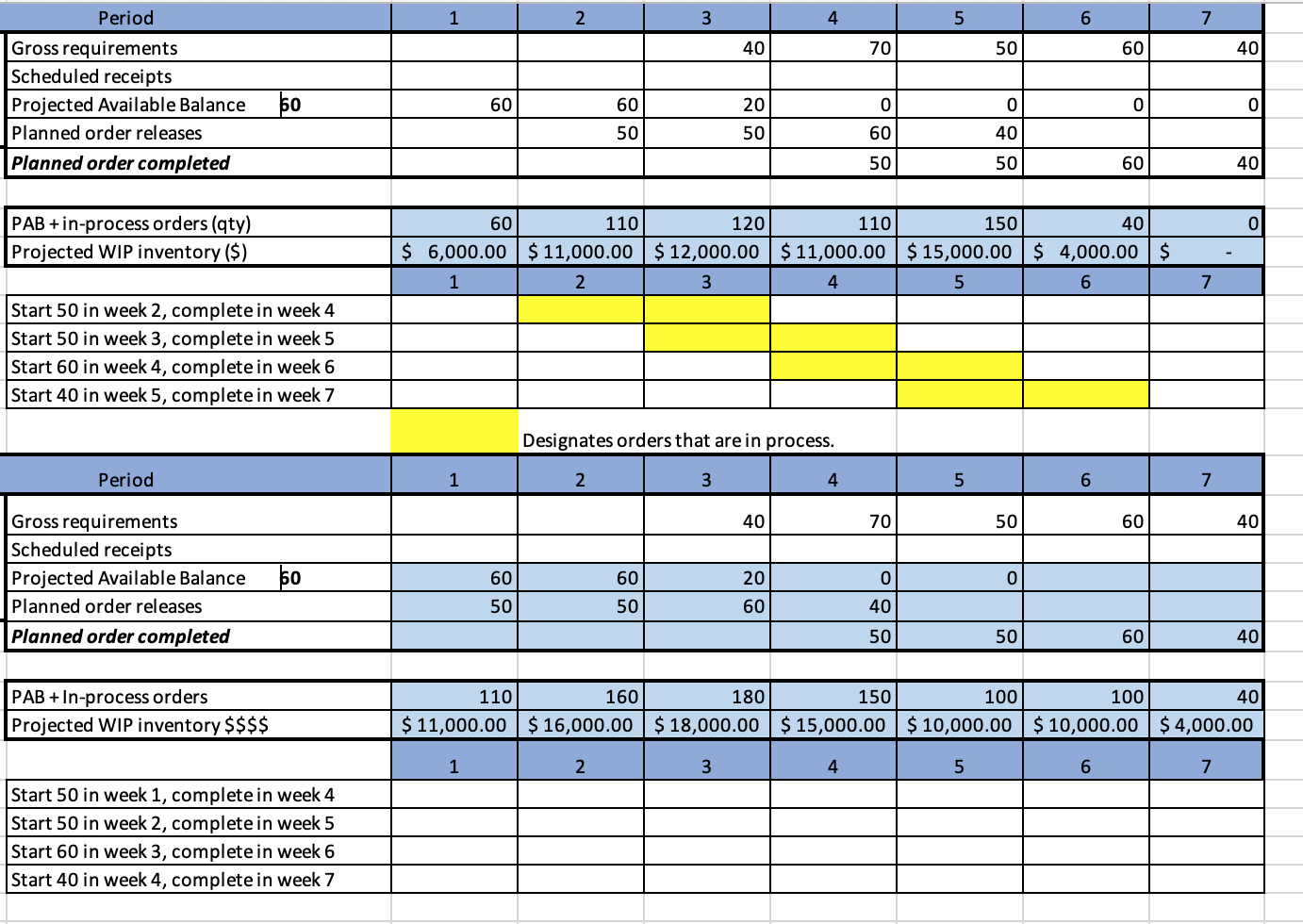

Additional Problem - Increasing Lead Time: You are the production control manager at Advanced Tech Manufacturing. Queue time is currently long in your production area and is causing high levels of WIP inventory and production is behind schedule. Part D is a new component that you are scheduled to begin manufacturing in the next two weeks. You want to give yourself some buffer time for completing the parts and you are exploring the decision to increase the material D lead time from 2 weeks to 3 weeks. The first MRP worksheet on the left shows the current planning data with a 2 week lead time. a} Calculate the "projected order quantity inprocess {PAB + inprocess orders (qtyn and "projected WIP inventory (5)" in the table. Assume that the standard perfunit cost of part D is $100. Notes: 7 Planned order completed" is a new row that I added to hopefully make the problem more clear. It is simply the period that the order in the "planned order release" column will be completed. "Projected order quantity inprocess" is the total quantity of all orders that have been released to production (manufacturing) for the given period. You should assume that order releases occur at the beginning of the week {8:00am Monday] and orders are completed at the beginning of the week (8:00am Monday). An order with a 2 week lead time will be ineprocess for two weeks 7 not three! , You will calculate the " Projected WIP inventory {5}" by multiplying the standard cost times the number of units ineprocess. b} The production control manager increases the lead time from 2 weeks to 3 weeks for part D and then runs MRP. What will the MRP worksheet look like after MRP? Complete the table including the new quantity inprocess and wip inventory (5} rows. c} Will the production control manager be better off by increasing the lead time from 2 weeks to 3 weeks? Why or why not? Be specific. Period 2 W 4 5 6 7 Gross requirements 40 70 50 60 40 Scheduled receipts Projected Available Balance 60 60 60 20 0 0 0 0 Planned order releases 50 50 50 40 Planned order completed 50 50 60 40 PAB + in-process orders (qty) 60 110 120 110 150 40 0 Projected WIP inventory ($) $ 6,000.00 $ 11,000.00 $ 12,000.00 $ 11,000.00 $ 15,000.00 $ 4,000.00 $ 1 2 3 4 5 6 7 Start 50 in week 2, complete in week 4 Start 50 in week 3, complete in week 5 Start 60 in week 4, complete in week 6 Start 40 in week 5, complete in week 7 Designates orders that are in process. Period 1 2 3 4 5 6 7 Gross requirements 40 70 50 60 40 Scheduled receipts Projected Available Balance 60 60 20 0 0 Planned order releases 50 50 60 40 Planned order completed 50 50 60 40 PAB + In-process orders 110 160 180 150 100 100 40 Projected WIP inventory $ $ $ $ $ 11,000.00 $ 16,000.00 $ 18,000.00 $ 15,000.00 $ 10,000.00 $ 10,000.00 $ 4,000.00 1 2 3 4 5 6 7 Start 50 in week 1, complete in week 4 Start 50 in week 2, complete in week 5 Start 60 in week 3, complete in week 6 Start 40 in week 4, complete in week 7

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts