Question: advanced replenishment problem The numbers that are listed in here are just examples and are not the optimal solution, i am looking for the optional

advanced replenishment problem

The numbers that are listed in here are just examples and are not the optimal solution, i am looking for the optional solution. This is a LP problem, where we are needing to set up an objective function, variables/params, and constraints to run a mathemathical model to find the objective. help would be greatly appreciated

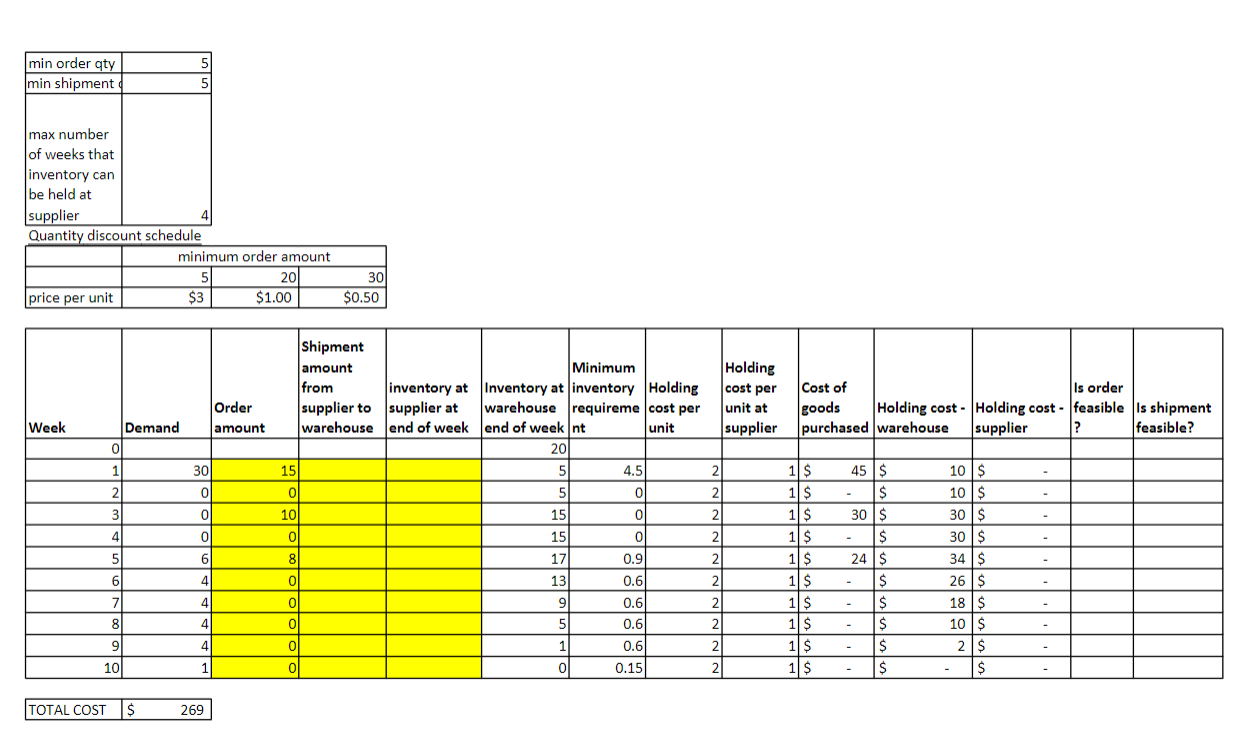

The attached spreadsheet contains demand data for ten weeks. You are to solve the following replenishment problem. Decide how much to order each week to minimize the total cost, which includes cost of purchasing and holding cost. In this new variant of the problem, we can hold inventory at our supplier as well as our own warehouse. Inventory held at the end of the week at the supplier and at our warehouse incurs a holding cost per unit. There is a minimum amount of inventory that must be on hand each week at the warehouse. If an order is placed in a period, the order amount must be at least the minimum order quantity (MOQ). When purchasing, there is a quantity discount, as shown in the spreadsheet. Inventory can only be held at the supplier for a certain number of weeks. After that, the inventory is automatically shipped to the warehouse. If a shipment is made, it must be at least the minimum shipment quantity (MSQ). The attached spreadsheet includes all of the data that you need as well as an example solution. (This example solution is not necessarily optimal. You need to find the optimal solution. single item data - MOQ and qty discount and VMI v2.xlsx min order ty min shipment 5 5 5 max number of weeks that inventory can be held at supplier Quantity discount schedule minimum order amount 5 20 price per unit $3 $1.00 301 $0.50 Holding cost per Cost of Is order unit at goods Holding cost - Holding cost - feasible is shipment supplier purchased warehouse supplier ? ? feasible? Order amount Week Demand 0 1 1 30 2 2 3 3 Shipment amount Minimum from inventory at Inventory at inventory Holding supplier to supplier at warehouse requireme cost per warehouse end of week end of week nt unit 20 15 5 4.5 0 0 5 0 10 15 0 0 15 0 8 17 0.9 0 13 0.6 0 9 0.61 0 5 0.6 0 1 0.6 0.15 21 2 2 0 4 0 2 - 5 6 2 1 $ 1 $ 1$ 1 $ 11 $ 1 $ 1 $ 1 $ 1 $ 1 $ 45 $ $ 30 $ $ 24 $ $ $ $ $ $ $ 10 S 10$ 30$ 30 IS 34 $ 26 $ 18 IS 10 S 2$ $ 6 6 4 4 7 4 2 21 2 2 8 4 - 9 4 10 1 2 TOTAL COST $ 269 The attached spreadsheet contains demand data for ten weeks. You are to solve the following replenishment problem. Decide how much to order each week to minimize the total cost, which includes cost of purchasing and holding cost. In this new variant of the problem, we can hold inventory at our supplier as well as our own warehouse. Inventory held at the end of the week at the supplier and at our warehouse incurs a holding cost per unit. There is a minimum amount of inventory that must be on hand each week at the warehouse. If an order is placed in a period, the order amount must be at least the minimum order quantity (MOQ). When purchasing, there is a quantity discount, as shown in the spreadsheet. Inventory can only be held at the supplier for a certain number of weeks. After that, the inventory is automatically shipped to the warehouse. If a shipment is made, it must be at least the minimum shipment quantity (MSQ). The attached spreadsheet includes all of the data that you need as well as an example solution. (This example solution is not necessarily optimal. You need to find the optimal solution. single item data - MOQ and qty discount and VMI v2.xlsx min order ty min shipment 5 5 5 max number of weeks that inventory can be held at supplier Quantity discount schedule minimum order amount 5 20 price per unit $3 $1.00 301 $0.50 Holding cost per Cost of Is order unit at goods Holding cost - Holding cost - feasible is shipment supplier purchased warehouse supplier ? ? feasible? Order amount Week Demand 0 1 1 30 2 2 3 3 Shipment amount Minimum from inventory at Inventory at inventory Holding supplier to supplier at warehouse requireme cost per warehouse end of week end of week nt unit 20 15 5 4.5 0 0 5 0 10 15 0 0 15 0 8 17 0.9 0 13 0.6 0 9 0.61 0 5 0.6 0 1 0.6 0.15 21 2 2 0 4 0 2 - 5 6 2 1 $ 1 $ 1$ 1 $ 11 $ 1 $ 1 $ 1 $ 1 $ 1 $ 45 $ $ 30 $ $ 24 $ $ $ $ $ $ $ 10 S 10$ 30$ 30 IS 34 $ 26 $ 18 IS 10 S 2$ $ 6 6 4 4 7 4 2 21 2 2 8 4 - 9 4 10 1 2 TOTAL COST $ 269

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts