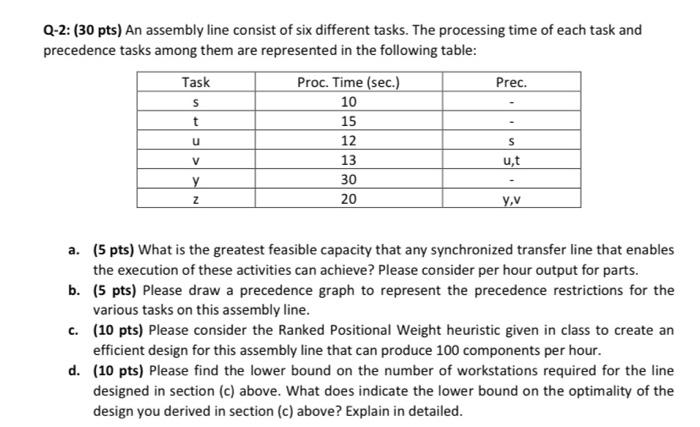

Question: An assembly line consist of six different tasks. The processing time of each task and precedence tasks among them are represented in the following table:

An assembly line consist of six different tasks. The processing time of each task and precedence tasks among them are represented in the following table:

a. (5 pts) What is the greatest feasible capacity that any synchronized transfer line that enables the execution of these activities can achieve? Please consider per hour output for parts.

b. (5 pts) Please draw a precedence graph to represent the precedence restrictions for the various tasks on this assembly line.

c. (10 pts) Please consider the Ranked Positional Weight heuristic given in class to create an efficient design for this assembly line that can produce 100 components per hour.

d. (10 pts) Please find the lower bound on the number of workstations required for the line designed in section (c) above. What does indicate the lower bound on the optimality of the design you derived in section (c) above? Explain in detailed.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock