Question: An assembly-line process has six tasks, as listed in the table below: Four workers (S1, S2, S3, and S4) are staffed to this assembly line,

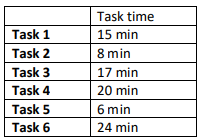

An assembly-line process has six tasks, as listed in the table below:

Four workers (S1, S2, S3, and S4) are staffed to this assembly line, and the assignment of tasks to each worker is as follows:

S1 does Task 1.

S2 does Tasks 2 and 3.

S3 does Tasks 4.

S4 does Tasks 5 and 6.

For the following questions, we assume that the process is operating at full capacity.

(a) Which worker is the bottleneck of the process? What is the process capacity in [units/hour]?

(b) What is the idle time of each worker in [minutes]?

(c) Assume a wage rate of $18 per hour. What is the direct labor cost in [$/unit]?

(d) Still assume a wage rate of $18 per hour. If we reassign Activity 5 from S4 to S3, what will be the new direct labor cost in [$/unit]? Is this reassignment an improvement? (keep 2 decimals)

\begin{tabular}{|l|l|} \hline & Task time \\ \hline Task 1 & 15min \\ \hline Task 2 & 8min \\ \hline Task 3 & 17min \\ \hline Task 4 & 20min \\ \hline Task 5 & 6min \\ \hline Task 6 & 24min \\ \hline \end{tabular}

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts