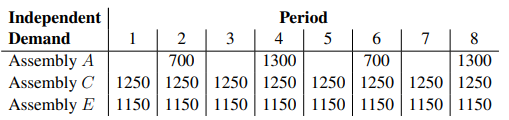

Question: An electronics company that produces subassemblies for clients has determined the following independent demand requirements for the next 8 weeks: Assemblies C and E are

An electronics company that produces subassemblies for clients has determined the following independent demand requirements for the next 8 weeks:

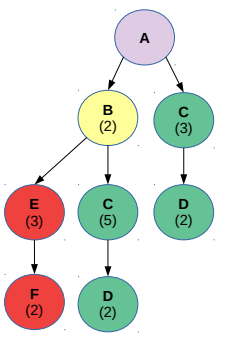

Assemblies C and E are themselves components of assembly A. The bill of materials for the subassemblies is:

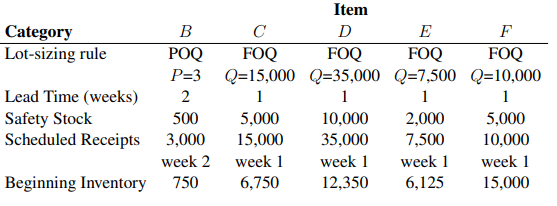

These assemblies are building components for many finished electronics products, and therefore the company tends to maintain large inventories of subassemblies C and E. The inventory management information for components B, C, D, and E is:

(a) Develop the production schedule for each component in assembly A. Make sure the independent demand for C and E are also included in the schedule.

(b) A breakdown at a competing company means that the company expects that demand for item E will increase by 1,000 units/week starting in week 6. What changes does the company have to implement to supply this new level of demand?

Independent Demand Assembly A Period 3 4 5 1300 1 2 700 8 700 1300 Assembly C 1250 1250 1250 1250 1250 1250 1250 1250 Assembly E 1150 1150 1150 1150 1150 1150 1150 1150 6 7 E (3) F (2) (2) (5) (2) A (3) D (2) Category Lot-sizing rule B POQ P=3 2 Item C D E FOQ FOQ FOQ Q=15,000 Q=35,000 Q=7,500 1 1 1 Lead Time (weeks) Safety Stock 500 5,000 Scheduled Receipts 3,000 15,000 week 2 week 1 Beginning Inventory 750 6,750 10,000 35,000 week 1 12,350 2,000 7,500 week 1 6,125 F FOQ Q=10,000 1 5,000 10,000 week 1 15,000

Step by Step Solution

3.42 Rating (155 Votes )

There are 3 Steps involved in it

Answer a Production schedule including the independent demand of C and E is following Steps to creat... View full answer

Get step-by-step solutions from verified subject matter experts