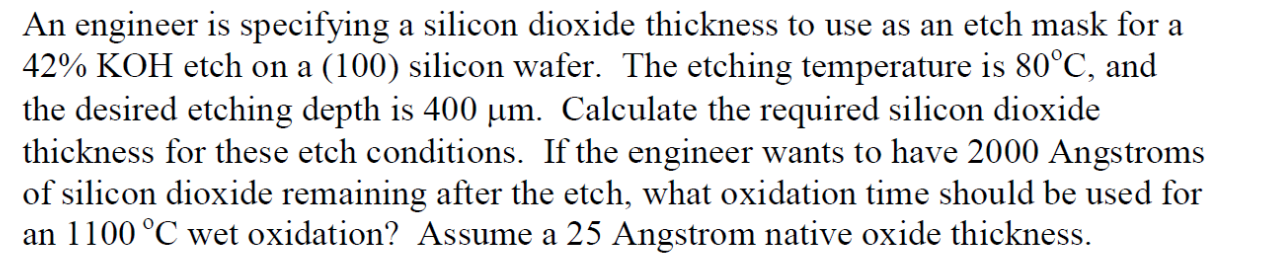

Question: An engineer is specifying a silicon dioxide thickness to use as an etch mask for a ( 4 2 % mathrm {

An engineer is specifying a silicon dioxide thickness to use as an etch mask for a mathrmKOH etch on a silicon wafer. The etching temperature is circmathrmC and the desired etching depth is mu mathrm~m Calculate the required silicon dioxide thickness for these etch conditions. If the engineer wants to have Angstroms of silicon dioxide remaining after the etch, what oxidation time should be used for an circmathrmC wet oxidation? Assume a Angstrom native oxide thickness. An evaporator is used to deposit aluminum. The aluminum charge is maintained at a uniform temperature of circmathrmC If the evaporator planetary has a radius of cm and the diameter of the crucible is cm what is the deposition rate of aluminum? Clearly state all assumptions.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock