Question: An engineer was tasked with evaluating a heat and power generation unit for an aluminium smelting plant. The management intends to expand the production facilities

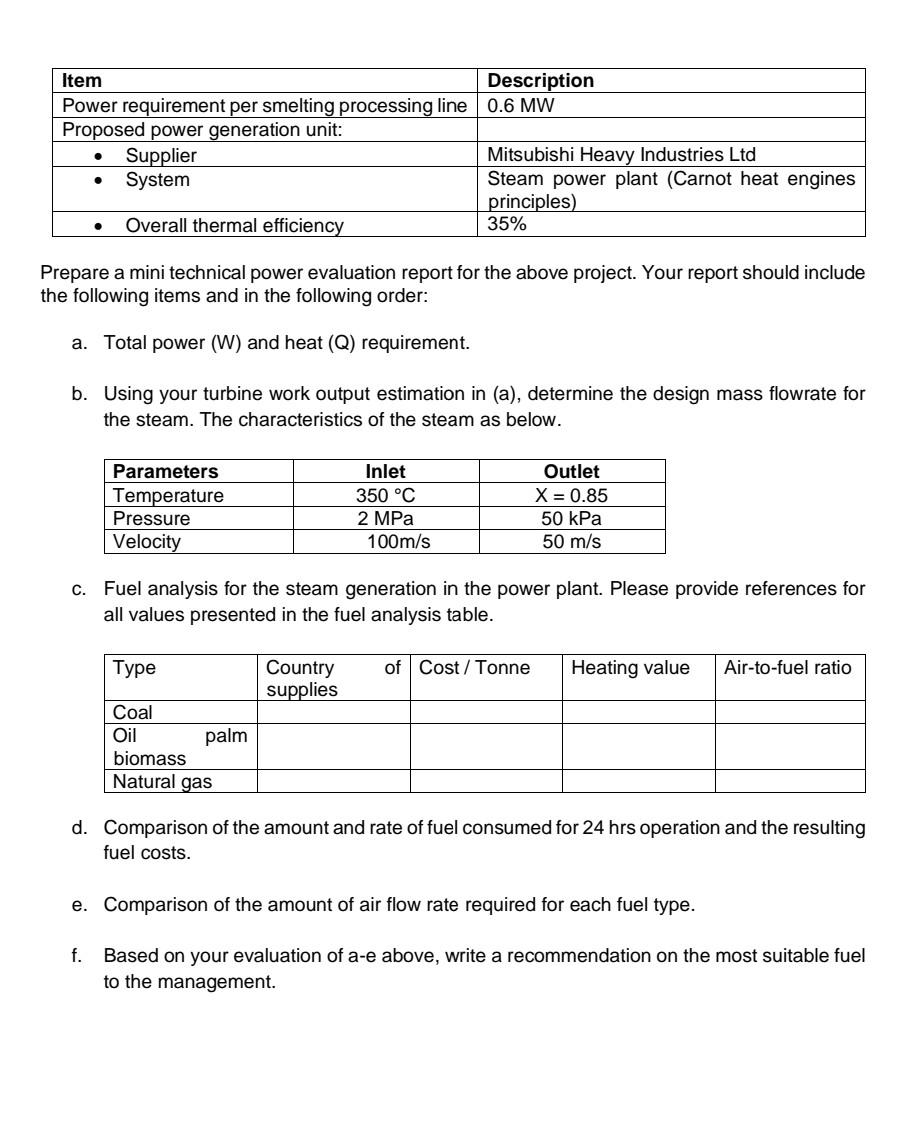

An engineer was tasked with evaluating a heat and power generation unit for an aluminium smelting plant. The management intends to expand the production facilities to meet growing demand for aluminium. The plan involves increasing the energy intensive smelting line from the present single line to three lines by end of 2022. To support the expansion plan, the company plans to install a self-sufficient power generation unit. Details of the energy requirement and the proposed power generation unit is given the following Table. Item Description Power requirement per smelting processing line 0.6 MW Proposed power generation unit: Supplier Mitsubishi Heavy Industries Ltd System Steam power plant (Carnot heat engines principles) Overall thermal efficiency 35% . Prepare a mini technical power evaluation report for the above project. Your report should include the following items and in the following order: a. Total power (W) and heat (Q) requirement. b. Using your turbine work output estimation in (a), determine the design mass flowrate for the steam. The characteristics of the steam as below. Parameters Temperature Pressure Velocity Inlet 350 C 2 MPa 100m/s Outlet X = 0.85 50 kPa 50 m/s C. Fuel analysis for the steam generation in the power plant. Please provide references for all values presented in the fuel analysis table. Type of Cost / Tonne Heating value Air-to-fuel ratio Country supplies Coal Oil biomass palm Natural gas d. Comparison of the amount and rate of fuel consumed for 24 hrs operation and the resulting fuel costs. e. Comparison of the amount of air flow rate required for each fuel type. f. Based on your evaluation of a-e above, write a recommendation on the most suitable fuel to the management

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts