Question: An industrial organization will evaluate its performance through six main traditional measurements product cost, manufacturing response, productivity; HR appraisal; resource status, and quality control. It

An industrial organization will evaluate its performance through six main traditional measurements product cost, manufacturing response, productivity; HR appraisal; resource status, and quality control. It was noticed that the existing product cost equals $ 90.0 per unit, and their target cost ranges from $85 to $95 per unit. The current selling price equals $150.0 per unit. They are looking to optimize the price to increase their competitive advantage in the market by a limited margin (+/-) 10 percent ($135.0-$165 per unit) while keeping the same profit margin. With this trend, the industrial organization wishes to minimize the manufacturing lead-time from 20 days to 15 days with keeping the average of 18 days. The organization is looking to increase the production rate from 2500 units to 3500 units per week by keeping the same resources (equipment, peopleetc.,) and maintaining 3000 units per week as an average. The organization is also looking to retain highly qualified people to minimize or eliminate the turnover rate, which was estimated by four percent to be three percent at the optimal case and five percent at the worst case. The availability of machines/equipment inside the plant is assessed as 90 percent. They wish to limit this value by a limit margin (+/-) five percent in the following years by updating and upgrading their maintenance team/crew. The quality department is also enhancement by applying new technologies and tools of inspection and testing from eight defectives to four defectives with keeping at least six defectives in average out of 5000 units.

Determine:

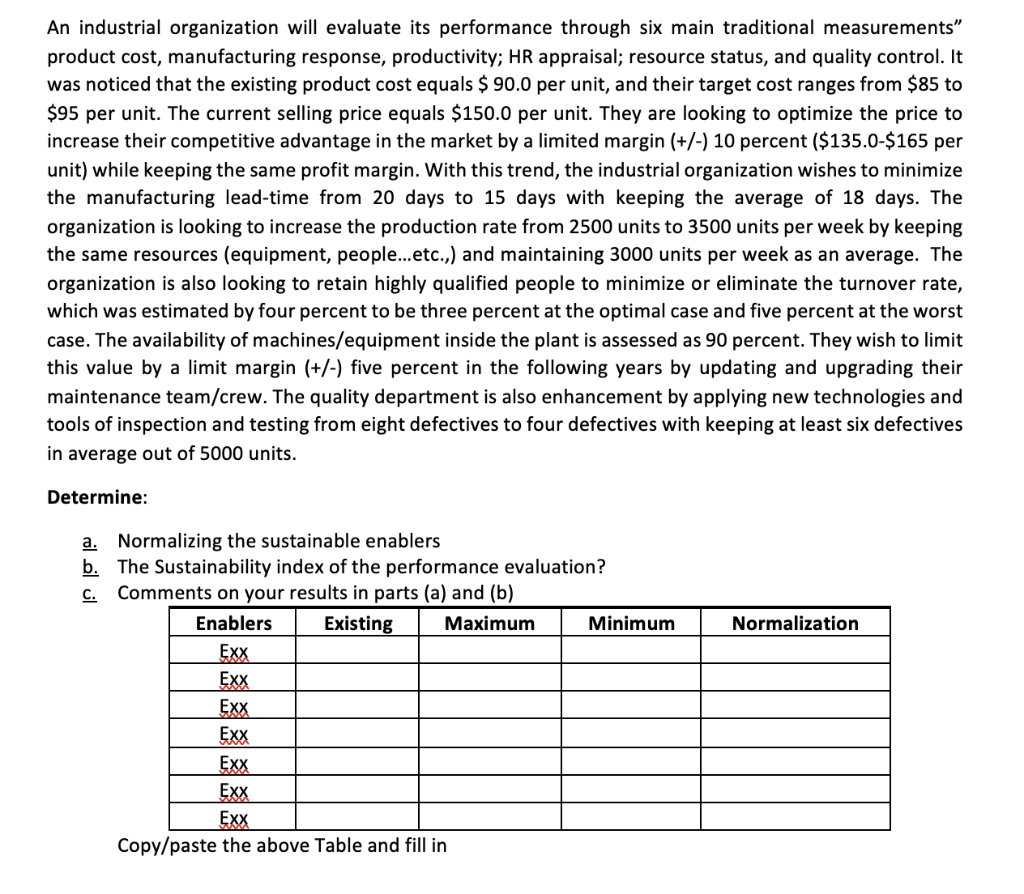

Normalizing the sustainable enablers

The Sustainability index of the performance evaluation?

Comments on your results in parts (a) and (b)

An industrial organization will evaluate its performance through six main traditional measurements" product cost, manufacturing response, productivity; HR appraisal; resource status, and quality control. It was noticed that the existing product cost equals $90.0 per unit, and their target cost ranges from $85 to $95 per unit. The current selling price equals $150.0 per unit. They are looking to optimize the price to increase their competitive advantage in the market by a limited margin (+/-) 10 percent (\$135.0-\$165 per unit) while keeping the same profit margin. With this trend, the industrial organization wishes to minimize the manufacturing lead-time from 20 days to 15 days with keeping the average of 18 days. The organization is looking to increase the production rate from 2500 units to 3500 units per week by keeping the same resources (equipment, people...etc.,) and maintaining 3000 units per week as an average. The organization is also looking to retain highly qualified people to minimize or eliminate the turnover rate, which was estimated by four percent to be three percent at the optimal case and five percent at the worst case. The availability of machines/equipment inside the plant is assessed as 90 percent. They wish to limit this value by a limit margin (+/-) five percent in the following years by updating and upgrading their maintenance team/crew. The quality department is also enhancement by applying new technologies and tools of inspection and testing from eight defectives to four defectives with keeping at least six defectives in average out of 5000 units. Determine: a. Normalizing the sustainable enablers b. The Sustainability index of the performance evaluation? c. Comments on your results in parts (a) and (b) Copy/paste the above Table and fill in

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts