Question: Analytics Exercise 9-2 Recently, Phil Harris, the production control manager at Brunswick, read an article on time-phased requirements planning. He was curious about how this

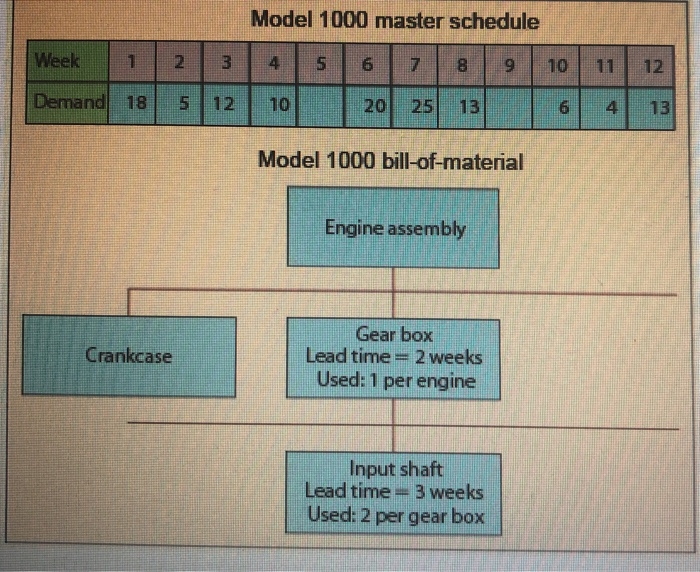

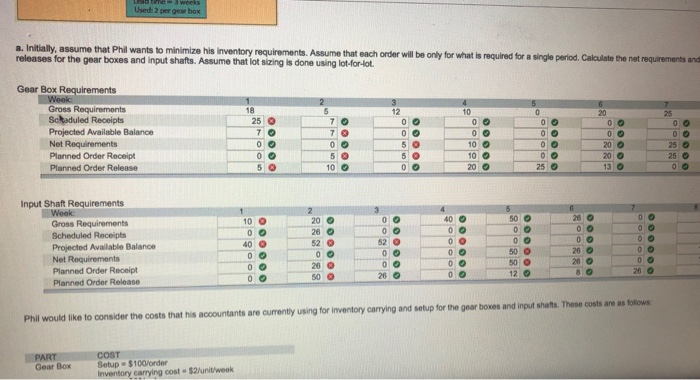

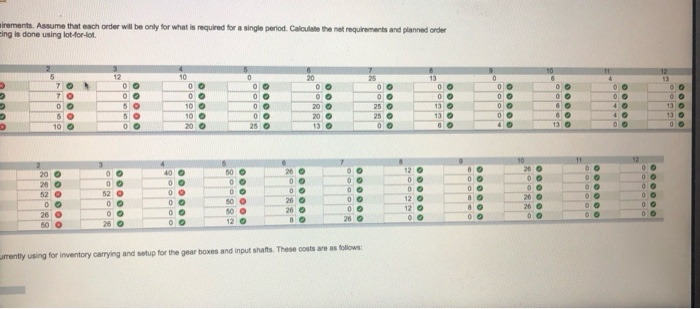

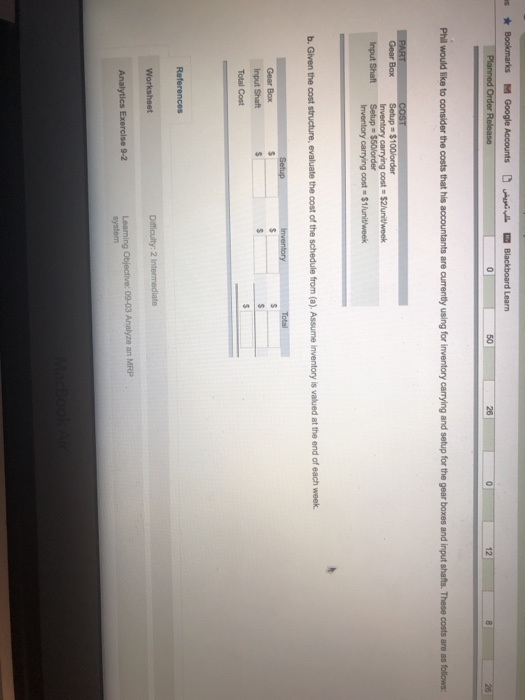

Model 1000 master schedule Week 12346 7 9 10 11 12 Demand 18 51210 20 25 13 64 13 Model 1000 bill-of-material Engine assembly Gear box Lead time- 2 weeks Used: 1 per engine Crankcase Input shaft Lead time- 3 weeks Used: 2 per gear box Used: 2 per gear box a. Initially, assume that Phil releases for the gear boxes and input shafts. Assume that lot sizing is done using lot-for-lot wants to minimize his inventory requirements. Assume that each order will be only for what is required for a single period. Calculate the net requirements and Gear Box Requirements Gross Requirements 18 12 10 20 25 25 O Projected Available Balance Net Requirements Planned Order Receipt Planned Order Release o 0 10 0 10 0 20 0 20 0 20 0 13 0 25 0 25 5 0 5 0 10 0 25 0 input Shaft Requirements 50 0 26 0 20 0 26 0 52 10 0 40 0 Gross Requirements Scheduled Receipts Projected Available Balance Net Requirements Planned Order Receipt Planned Order Release 40 0 52 0 26 26 0 50 50 0 50 0 12 0 26 0 o O 20 the costs that his accountants are currently using for inventory carrying and setup for the gear boxes and input shafts. These costs are as follows Gear BoxSetup $100/forder Inventory carrying cost $2/unitweek irements. Assume that each order wil be only for what is required for a single period. Calculate the net requirements and planned onder ing is done using lot-for-ot. 12 10 20 25 20 0 20 o 13 0 250 : 130 00 25 O 13 0 13 0 10 0 20 0 25 0 40 0 50 0 26 0 26 0 20 O 26 0 52 0 26 26 0 12 12 26 o 26 26 O 50 0 12 0 26 0 26 0 mently using for inventory carrying and setup for the gear boxes and input shafts. These oosts are as tollow 28 Phil would like to b. Given the cost structure, evaluate the cost of the schedule from (a). Assume inventory is valued at the end of each week Total Cost

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts