Question: Analytics Exerclse 9-1 (Algo) Recently, Phil Herris, the production control manager at Brunswick, read on article on time-phased requirements planning. He was curious about how

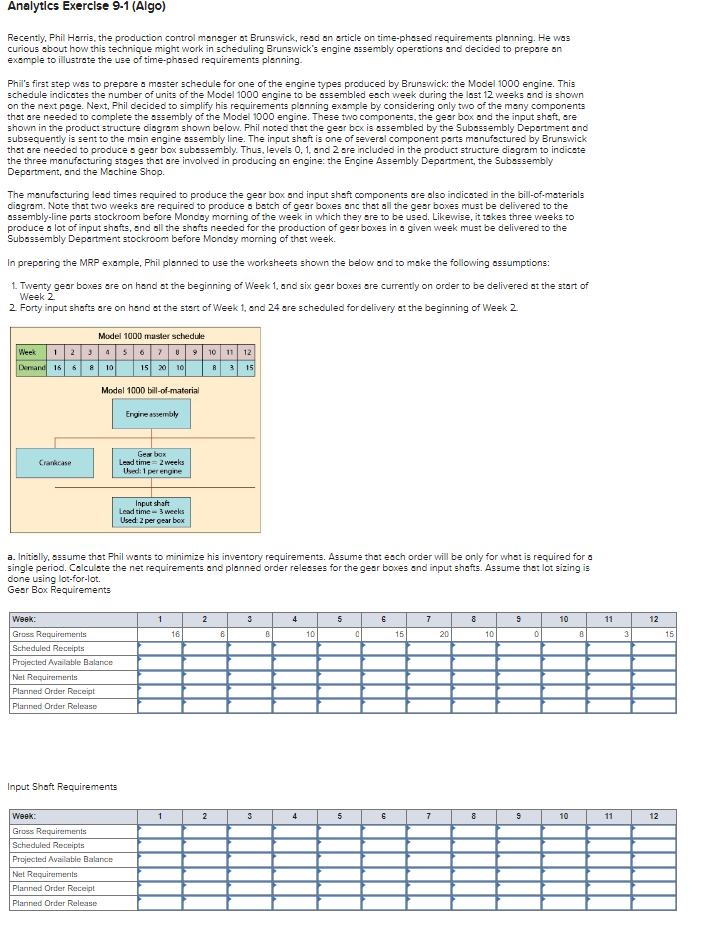

Analytics Exerclse 9-1 (Algo) Recently, Phil Herris, the production control manager at Brunswick, read on article on time-phased requirements planning. He was curious about how this technique might work in scheduling Brunswick's engine assembly operations and decided to prepare an example to illustrate the use of time-phosed requirements planning. Phil's first step wos to prepare s master schedule for one of the engine types produced by Brunswick: the Model 1000 engine. This schedule indicates the number of units of the Model 1000 engine to be ussembled each week during the last 12 weeks and is shown on the next poge. Next, Phil decided to simplify his requirements plonning exemfle by considering only two of the meny components that are needed to complete the sssembly of the Model 1000 engine. These two components, the gear box and the input shaft, are shown in the product structure disgram shown below. Phil noted that the gear bex is assembled by the Subossembly Deportment and subsequently is sent to the moin engine sssembly line. The input shaft is one of several component parts manufactured by Brunswick thet are needed to produce a gear box subsssembly. Thus, levels 0,1 , and 2 are included in the product structure diegrom to indicate the three manufacturing stages that are involved in producing on engine: the Engine Assembly Department, the Subsssembly Deportment, and the Machine Shop. The manufacturing lead times required to produce the gear box and input shaft components are also indicated in the bill-of-materials diagram. Note that two weeks are required to produce o botch of gear boxes onc that all the gear boxes must be delivered to the ossembly-line ports stockroom before Monday morning of the week in which they ore to be used. Likewise, it takes three weeks to produce s lot of input shafts, and oll the shafts needed for the production of gear boxes in a given week must be delivered to the Subossembly Department stockroom before Mondsy morning of that week. In prepsring the MRP example, Phil planned to use the worksheets shown the below and to make the following ossumptions: 1. Twenty gear boxes are on hand at the beginning of Week 1 , and six gear boxes are currently on order to be delivered at the start of Week 2 2. Forty input shafts are on hand at the start of Week 1 , and 24 are scheduled for delivery at the beginning of Week 2 . a. Initiolly, assume that Phil wants to minimize his inventory requirements. Assume that each order will be only for what is required for a single period. Calculate the net requirements and planned order relesses for the gear boxes and input shafts. Assume that lot sizing is done using lot-for-lot. Geor Box Requirements Input Shaft Requirements

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts