Question: Analyze the CASE STUDY, SPECIALITY PACKING CORPORATION, PART A ( Pages 207-208 of your textbook) and answer all Discussion questions at the end of the

Analyze the CASE STUDY, SPECIALITY PACKING CORPORATION, PART A (Pages 207-208 of your textbook) and answer all Discussion questions at the end of the Case.

Use software package (Excel) wherever appropriate

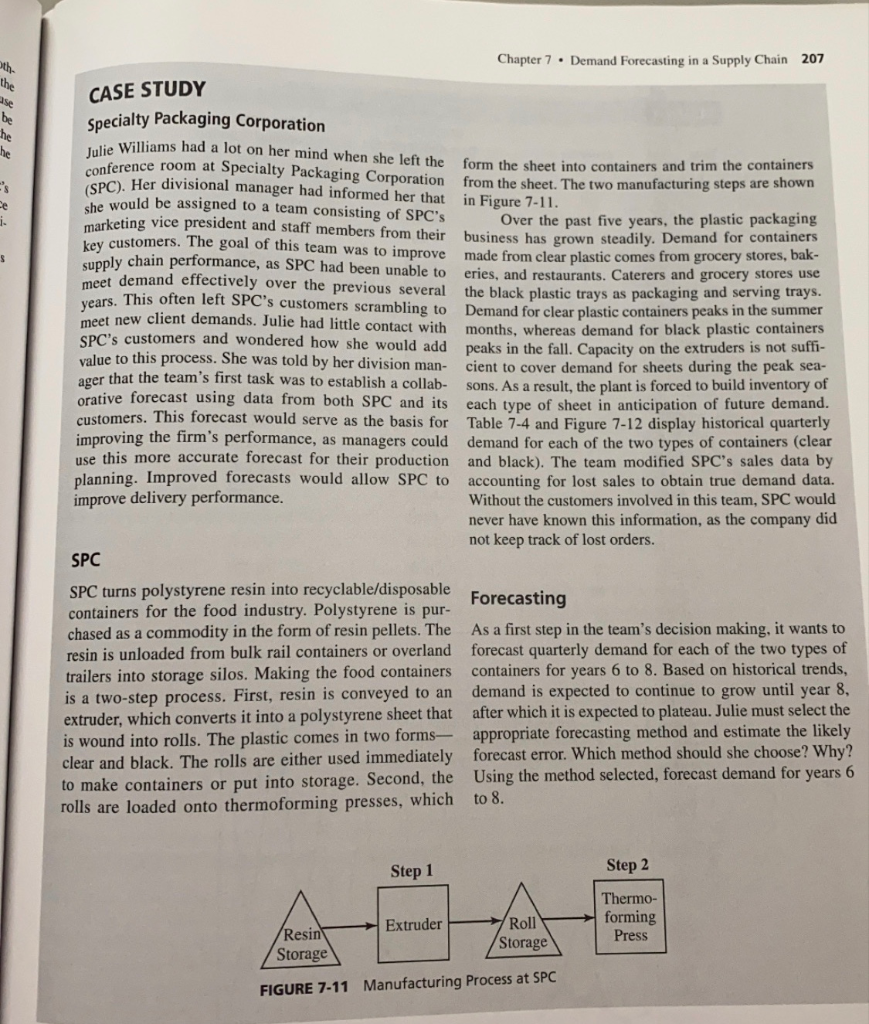

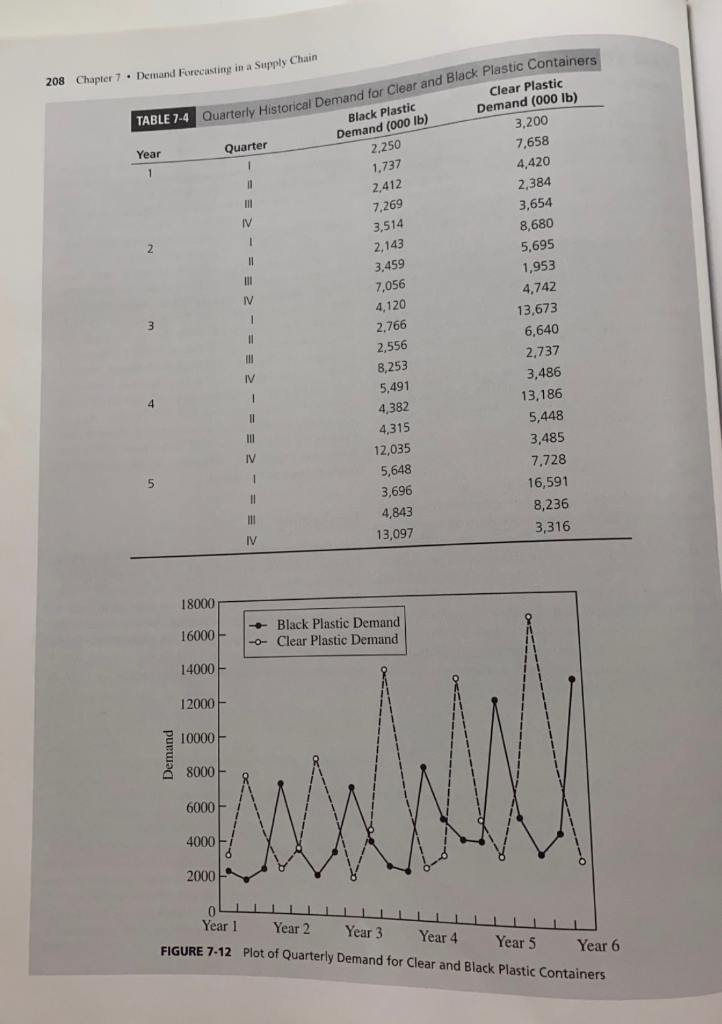

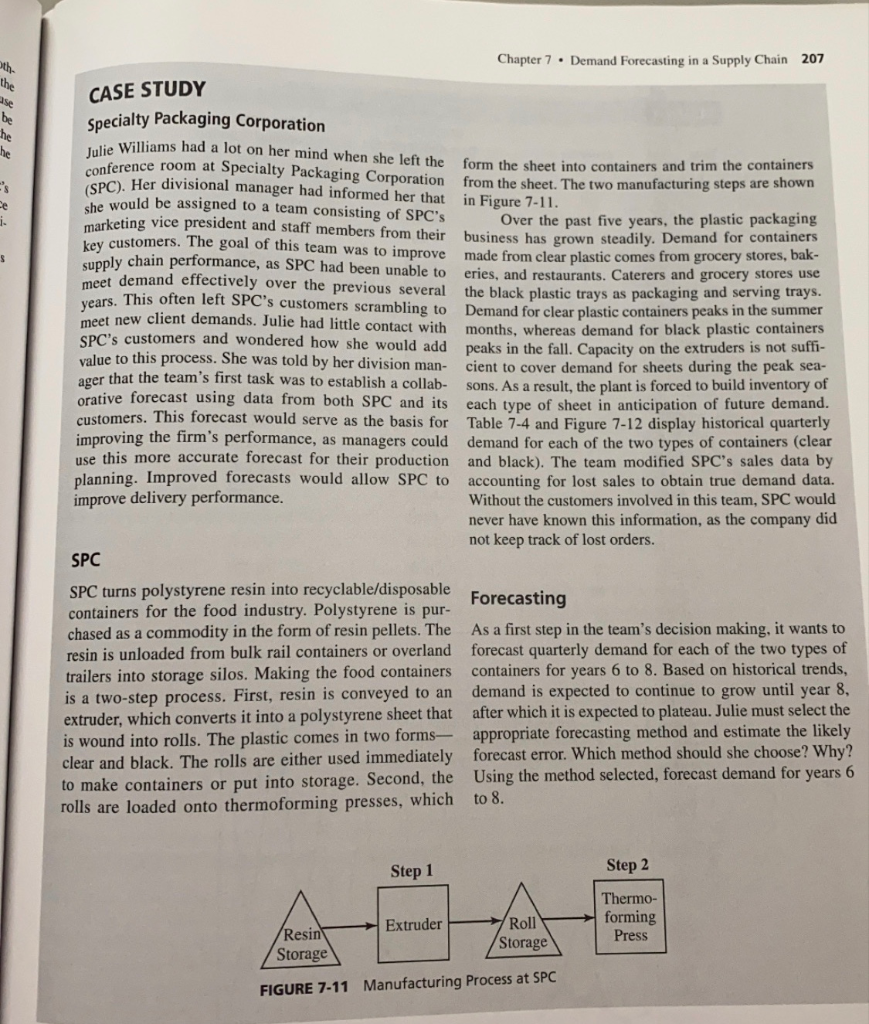

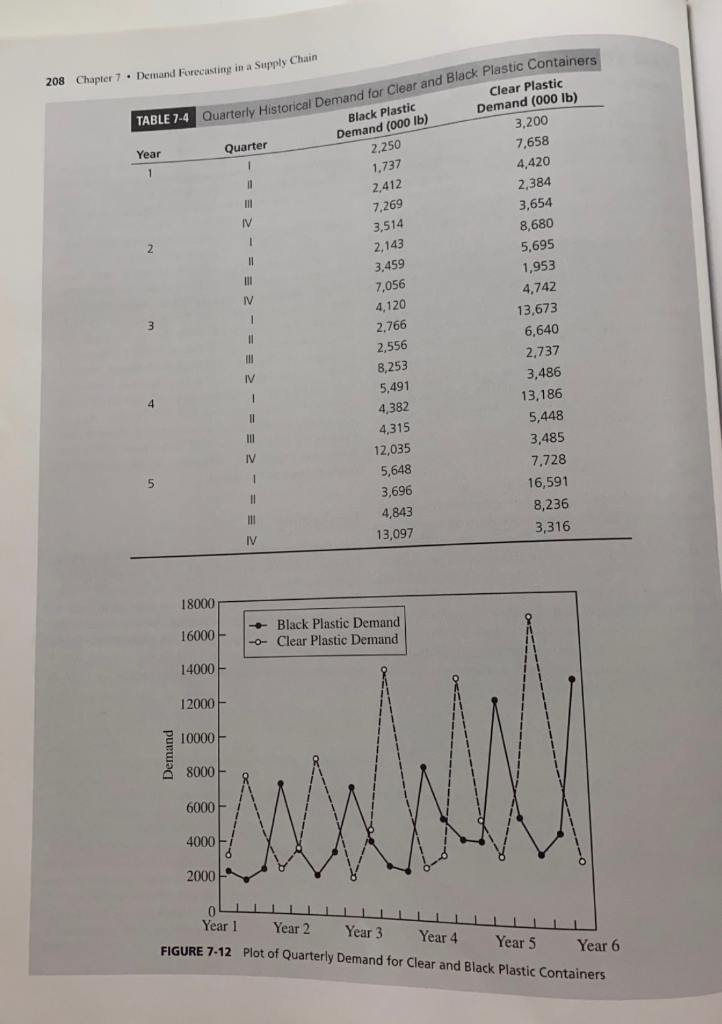

Chapter 7 . Demand Forecasting in a Supply Chain 207 CASE STUDY Specialty Packaging Corporation Williams had a lot on her mind when she left the ference room at Specialty Packaging Corporation form the sheet into containers and trim the containers form the sheet into containers an PC). Her divisional manager had informed her that from the sheet. The two manufacturing he would be assigned to a team consisting of SPC's in Figure 7-11. Over the past five years, the plastic marketing vice president and staff members from members from their business has grown steadily. Demand for containers key customers. The goal of this team was to improve made from clear plastic comes from grocery so supply chain performance, as SPC had been unable had been unable to eries, and restaurants. Caterers and grocery stores use meet demand effectively over the previous several the black plastic trays as packaging and serving years. This often left SPC's customers scrambling s customers scrambling to Demand for clear plastic containers peaks in the summer meet new client demands. Julie had little contact with months, whereas demand for black plastic containers SPC's customers and wondered how she would add peaks in the fall. Capacity on the extruders is not sunt value to this process. She was told by her division man- cient to cover demand for sheets during the peak sea- ager that the team's first task was to establish a collab- sons. As a result, the plant is forced to build inventory of orative forecast using data from both SPC and its each type of sheet in anticipation of future demand. customers. This forecast would serve as the basis for Table 7-4 and Figure 7-12 display historical quarterly improving the firm's performance, as managers could demand for each of the two types of containers (clear use this more accurate forecast for their production and black). The team modified SPC's sales data by planning. Improved forecasts would allow SPC to accounting for lost sales to obtain true demand data. improve delivery performance. Without the customers involved in this team, SPC would never have known this information, as the company did not keep track of lost orders. SPC SPC turns polystyrene resin into recyclable/disposable Forecasting Enre containers for the food industry. Polystyrene is pur- chased as a commodity in the form of resin pellets. The As a first step in the team's decision making, it wants to resin is unloaded from bulk rail containers or overland forecast quarterly demand for each of the two types of trailers into storage silos. Making the food containers containers for years 6 to 8. Based on historical trends, is a two-step process. First, resin is conveyed to an demand is expected to continue to grow until year 8, extruder, which converts it into a polystyrene sheet that after which it is expected to plateau. Julie must select the is wound into rolls. The plastic comes in two forms- appropriate forecasting method and estimate the likely clear and black. The rolls are either used immediately forecast error. Which method should she choose? Why? Using the method selected, forecast demand for years 6 to make containers or put into storage. Second, the to 8. rolls are loaded onto thermoforming presses, which Step 1 Step 2 Thermo- forming Press Extruder Resin Storage Roll Storage FIGURE 7-11 Manufacturing Process at SPC 208 Chapter 7. Demand Forecasting in a Supply Chain TABLE 7-4 Quarterly Historical De Quarter Year 7,658 4,420 - 7-4 Quarterly Historical Demand for Clear and Black Plastic Containers Clear Plastic Black Plastic Demand (000 lb) Demand (000 lb) 2,250 3,200 1,737 2,412 2,384 3,514 = = 7,269 = 2,143 = 3,459 = = 7,056 4,120 2,766 = = 2,556 = 8,253 3,654 8,680 5,695 1,953 4,742 13,673 6,640 2,737 3,486 13,186 5,448 3,485 7.728 16,591 8,236 3,316 = 5,491 = 4,382 = = = 4,315 12,035 5,648 3,696 4,843 = = = 13,097 z 18000 16000 - Black Plastic Demand Clear Plastic Demand 14000 12000 10000 Demand 8000 6000 4000 ! 2000 LLLLLLLLLLLLLLLLLLL Year 1 Year 2 Year 3 Year 4 Year 5 Year 6 FIGURE 7-12 Plot of Quarterly Demand for Clear and Black Plastic Containers