Question: Answer in marked spaces. If needed, add additional writing space with clear reference to the question number A. ARTICLE 1 JAPAN - According to this

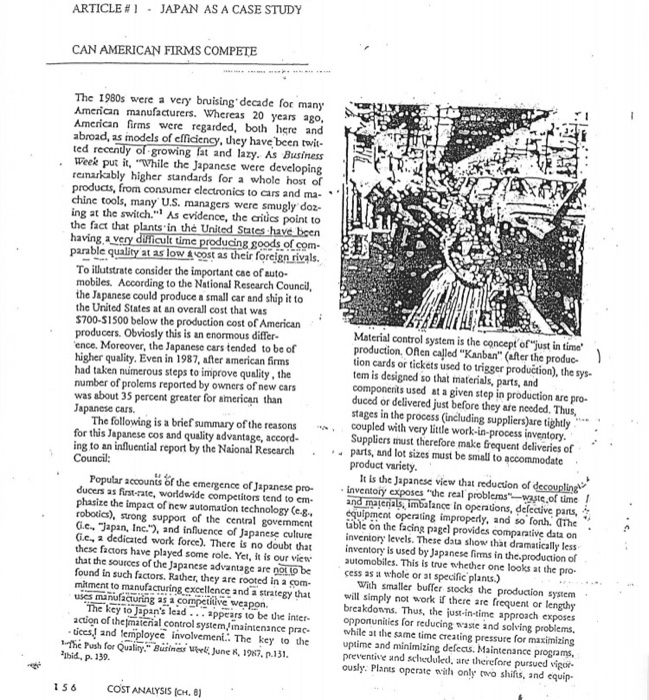

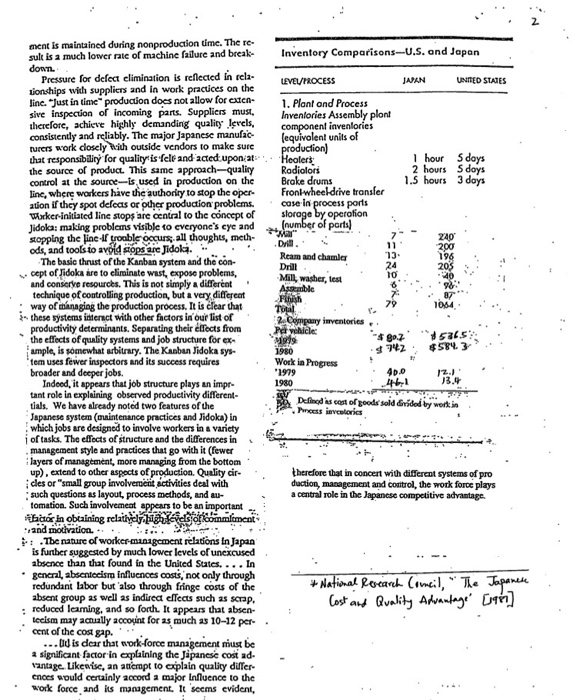

Answer in marked spaces. If needed, add additional writing space with clear reference to the question number A. ARTICLE 1 JAPAN - According to this article 1. The Japanese use 'manufacturing as a competitive weapon'. What do you think 'competitive weapon' means? Explain briefly 2. What other sorts of competitive weapons' can you list that exist today in our firms and industries 3. The table at the end of the Japan article shows inventory levels have tended to be lower in Japan than in the US at that time. List 4 ways from the article to show how that helped the Japanese to lower their costs. -briefly explain to make the connection clear. 4. Highlight in the text of the article evidence of Division of Labor' and upload/ or type the texts you identify by quoting between S. Circle the best answer: According to the article, Japan could sell its cars for $1500 lower compared to the US. mostly due to: a Cheaper labor b. Use of automation c Low absenteeism d. Managing systems e. Economies of scale 6. Support your answer in '6' by listing evidence from the text - at least 3: 7. Quote one example form the text of the Jidoka system "....." then show graphically the effect on one of the Productivity Curves we studied in this chapter. B. ARTICLE No 2: Bloomberg B.Week, "Farewell to Good Times and Nespresso Below are changes mentioned in the article that will affect the cost of operations in Big mining companies. For each question, state the cost component to be affected first (MC?VC?FC?) and WHY. Then show graphically the effects of the change on the all short cost curves together (like we did in class) A brief explanation is required to make your connections clear. (otherwise, cannot evaluate). Label everything Graph in spaces provided (a) BHP Billiton, the world's biggest mining company trimmed about $3.4 billion in costs through such changes as refueling trucks on site in mining pits to avoid wear and tear on expensive tires from driving to faraway fuel stations, (b) Rio Tinto, another major mining company) with $ 50 billion in revenue worked hard to save as little as $60,000 by reducing its servings of hot meat pies and sausages rolls they used to offer their employees. They were quoted as saying "Every pie counts!" C. COMPARING ARTICLE 1 (JAPAN WITH ARTICLE on 3M For questions 1-3 you will be asked to make notations on the text where appropriate. So, print, do the Markings on the article, and upload (or take picture and upload if need to ) If you cannot print the article, then number the paragraphs (there are 13) and list the text by" quoting" and specify which concept this refers to. You MUST mention the paragraph so I can easily locate it. 1.. Circle in the text 6 factors that could cause the MP of their workers to change. Also write in the margin "MP next to the text as an annotation. 2. In the text underline (single line) 3 factors that caused their VC to change. Annotate beside the text by writing "VC" in the margins. 3. In the text put double lines under 4 factors that caused the Fixed Costs of the company to change and annotate in the margin beside the text "FC" 4. What would you say is 3 M's "competitive weapon" and how did that help reduce the company's costs? Write 10 lines using 4 technical terms related to costs. Use additional writing space. 5. Culture does matter, even in the business world!! How different are employee relations in the US form the ones described in Japan? To answer consider the company 3M as a representative of US Corporate world and supply answers to the following (add more writing space) (0 Find/write between quotations three (3) examples from 3M. (11) For each, comment by comparing and contrasting with what happens in Japan. ARTICLE #1 - JAPAN AS A CASE STUDY CAN AMERICAN FIRMS COMPETE The 1980s were a very bruising decade for many American manufacturers. Whereas 20 years ago. American firms were regarded, both here and abroad, as models of efficiency, they have been twit- ted recently of growing lat and lazy. As Business Week put it, "While the Japanese were developing remarkably higher standards for a whole host of products, from consumer electronics to cars and ma- chine tools, many U.S. managers were smugly doz- ing at the switch. As evidence, the critics point to the fact that plants in the United States have been having a very difficult time producing goods of com- parable quality at as low cost as their foreign rivals. To illustrate consider the important cac of auto- mobiles. According to the National Research Council, the Japanese could produce a small car and ship it to the United States at an overall cost that was 5700-S1500 below the production cost of American producers. Obviosly this is an enormous differ- ence. Moreover, the Japanese cars tended to be of higher quality. Even in 1987, after american firms had taken numerous steps to improve quality, the number of prolems reported by owners of new cars was about 35 percent greater for american than Japanese cars. The following is a brief summary of the reasons for this Japanese cos and quality advantage, accord- ing to an influential report by the Naional Research Council: Material control system is the concept of "just in time production. Often called "Kanban" (after the produc- tion cards or tickets used to trigger production), the sys- tem is designed so that materials, parts, and components used at a given step in production are pro- duced or delivered just before they are needed. Thus, stages in the process (including suppliers)are tightly coupled with very little work-in-process inventory. Suppliers must therefore make frequent deliveries of parts, and lot sizes must be small to accommodate product Variety. It is the Japanese view that reduction of decoupling Inventory exposes the real problemas-waste of time! and materials, imbalance in operations, delective parts, equipment operating improperly, and so fonh (The uble on the facing pagel provides comparative data on inventory levels. These data show that dramatically less inventory is used by Japanese firms in the production of automobiles. This is true whether one looks at the pro- cess as a whole or a specific plants.) With smaller buffer stocks the production system will simply not work if there are frequent or lengthy breakdowns. Thus, the just-in-time approach exposes opportunities for reducing waste and solving problems. while at the same time creating pressure for maximizing uptime and minimizing defects. Maintenance programs, preventive and scheduled, are therefore pursued vigor ously. Plants operate with only wo shifts, and equip- Popular accounts of the emergence of Japanese pro- ducers as first-rate, worldwide competitors tend to em phasize the impaa of new automation technology (es. robotics), strong support of the central goverment Ge, Japan, Inc."), and influence of Japanese culture Ge, a dedicated work force). There is no doubt that these factors have played some role. Yet, it is our views that the sources of the Japanese advantage are not to be found in such factors. Rather, they are rooted in a com- mitment to manufacturing excellence and a strategy that uses manufacturing as a competitive weapon The key to Japan's lead... appears to be the inter- action of the material control system, inaintenance prace tices and employee involvement. The key to the The Push for Quality. Butins e June 1917. p.131. ibid. p. 139. have playforce). There Japanese 156 COST ANALYSIS (CH. 6] 3 days ZAO Drill. 24 2031 7 79 $942. $5843 ment is maintained during nonproduction time. The re- sult is a much lower rate of machine failure and break Inventory Comparisons-U.S. and Japan down.. Pressure for defect elimination is reflected in rela- LEVEL/PROCESS JAJAN UNITED STATES Lionships with suppliers and in work pracuces on the line. Just in time production does not allow for exten- 1. Plant and Process sive inspection of incoming parts. Suppliers must, Inventories Assembly plont therefore, achieve highly demanding quality levels, component invenlories consistently and reliably. The major Japanese manufac (equivalent units of turers work closely with outside vendors to make sure production) that responsibility for quality is fele and acted upon at.. 1 hour 5 days the source of product. This same approach-quality Radiolors hours Sdoys control at the source is used in production on the Brake drums 1.5 hours line, where workers have the authority to stop the oper Front-wheel drive transfer auon if they spor defects or other production problems. cose in process ports Waker-initiated line stops are central to the concept of storage by operation Jidoka: making problems visible to everyone's cyc and number of parts) stopping the line-If trouble occurs all thoughts, meth- ods, and tools to avoid stops are Jidoka... .. Ream and chamlar 13 The basic thrust of the Kanban system and the con- 196 Drill cept of Jidoka are to climinate wast, expose problems, Mill, washer, test 10 . and conserve resources. This is not simply a different Assemble 6 *98 . technique of controlling production, but a very differeat . 87* Filish : way of managing the production process. It is clear that Total 1054 . . these systems interact with other factors in our list of 2. Company inventories productivity determinants. Separating their effects from Pa vehicle the effects of quality systems and job structure for ex M918 goz #5215 . ample, is somewhat arbitrary. The Kanban Jidoka sys- 1980 tem uses fewer inspectors and its success requires Work in Progress broader and deeper jobs. . .40.0 12. Indeed, it appears that job structure plays an impr- 1980 6 13.4 tant role in explaining observed productivity different UPO tials. We have already noted two features of the 38 Definodis cost of goods sold vided by workin Japanese system (ouaintenance practices and Jidoka) in which jobs are designed to involve workers in a variety i of tasks. The effects of structure and the differences in management style and practices that go with it (fewer . layers of management, more managing from the bottom up), extend to other aspects of production. Quality air- therefore that in concert with different systems of pro des or "small group involvement activities deal with duction management and control, the work force plays such questions as layout, process methods, and au- a central role in the Japanese competitive advantage. tomation. Such involvement appears to be an important Ebicos in obtaining relatives i etkinliment and motivation..... .. The nature of worker-management relations In Japan is further suggested by much lower levels of unexcused absence than that found in the United States.... In general, absenteeism influences costs, not only through redundant labor but also through fringe costs of the absent group as well as indirect cliccts such as scrap. : reduced learning, and so forth. It appears that absen- tecism may actually account for as much as 10-12 per.. cent of the cost gap. . ... Od is dear that workforce management must be a significant factor in explaining the Japanese cost ad. vantage. Likewise, an atempt to explain quality differ ences would certainly accord a major influence to the work force and its management. It seems evident, 1979 Poss incloric . . National Research Council, The Japanese Cost and Quality Advantage [an] I WSi april 20?, 2002 IN THE LEAD By CAROL HYMOWITZ How Leader at 3M Got His Employees To Back Big Changes THERE TXTILE MR. MCNERNEY 535 YY talked about return investment and the use of best practices across diverse busi- nesses, 3M managers, accustomed to free rein in running their departments, talked about commercializing new Inventions. De- termined to find a common language with middle management, Mr. McNerey took 15 2002 Dow Jones Company, Inc. All Rights Re top executives to a two-day, off-site meeting to reformulate 3M's core values. Their list included phrases such as "chart the course, "energize and inspire others and "deliver results." He set an ambitious goal of increasing sales and operating earnings by at least 10% each year-nearly twice the rate of the past decade. But he resisted barking orders and set about trying to win the hearts and minds of employees. You can't order change," he says. After all, there's only one of me and 75,000 of them.- Mr. Burgstaller says about the numerous meetings with employees: Jim doesn't say. "You've got to do this. Instead he says. 3M has this tremendous reputation and global presence and great technology, and I see all these opportunities we can leverage if we get on the same page and help each other.' Since Mr. McNerey's arrival, 3M has be NO MATTER HOW Intelligent a leader's pun pooling supply purchases on a global ba- sis to get lower prices, and shifted some I stratery for change, it will fail without .. manufacturing to lower cost sites abroad. the dedicated support of the rank and file He also asked 334 managers to rank on a Winning that support often requires more ef- curve every employee reporting to them-a fort than devising the strategy itsell System long used at GE but which backfired W. James McNerney Jr., chief executive at Ford under former CEO Jacques Nasser. of 3M Co., has learned this lesson. Eighteen months ago, when he took over the manufac M R. MCNERNEY AND his top lieuten. turing company that makes everything from L1 ants had to gain acceptance for the Scotch tape to fly fishing gear and pharma new grading system. They reminded employ. ceuticals, 3M's sales were anemic and it ces that in past surveys they had com hadn't launched a blockbuster product in plained that underperformers were too pro- several years. Mr. MeNerey, an 18-year vet. iected at the company. For example, all eran of General Electric who had been in managers above a certain level at 3M were the race to succeed granted stock options each year. Now, op Jack Welch, goldly tions will be granted only to those with bet shook things up with ter-than-average performance grades. 334 one tactic alter an- other from the GE . had a tendency to overvalue experience and undervalue leadership," says Mr. McNerney management book. He pared costs, Aggressive your employees applaud the cut the work force new system. In the past, they had to prove themselves in a series of narrowly defined by almost 10% and Sobs. Now, they are encouraged to step out introduced Slx Sigma, the process . of their niches, and even leapfrog veteran employees. management system that breaks down ev- It has been a difficult balancing act: boosting growth through cost cutting, acqui- ery task into incre sitions, and concentration on leading prod- ments measured ucts and big markets, but preserving 3M's against a perfect model. hallmark creativity. The company's top-notch engineers used Mr. McNemey, the first outsider to rin 3M in its 100-year history, soon found that to be left alone-with ample funding-to do . what was routine at GE was allen at 3M, He" research. Today, top executives specify was the only one who showed up at meet- where RD money is spent. Over the next several years, the company will likely ings without a tie. His blunt and probine shrink its list of 50,000 products to the most questions, rapid speech and Insistence on seeing lots of financial data before making profitable. decisions Jolted many 3M managers. 3M people wake up every morning think This is a homegrown place with a colle ing about what new product they can bring atmosphere where the emphasis on be to market," says Mr. MeNerey. "Innovation in nice to each other means issues haven't is in their DNA-and i ll that entrepre- always surfaced in an honest way." says , neurial spirit I will have failed. My job is to build on that strength, corral and focus it." Bob Bursa Mer, senior vice president of business development and corporate ser Vices, and a 31-year vetetan of M. Brail comments to inteleads.com. To see other recent columns, go to Career Jour mol.com. Inventory Comparisons--U.S. ond Japan LEVEV PROCESS JAAN UNITED STATES 1. Plant and Process Inventories Assembly plant component inventories (equivalent units of production) Hoolers Radiolors Broke drums Front wheel drive transfer cose in process ports storage by operation (number of parts) Mar 1 hour days 2 hours Sdays 1.5 hours 3 days 220 Dr. Ream and chamla Drill Mill, washer, test Assemble Fish Total 2. Company inventories Pa vehick 1919 1980 Work in Progress 1979 1980 STU . 12.) 46 33.9 Definodis cost of goods sold Poss incularis Answer in marked spaces. If needed, add additional writing space with clear reference to the question number A. ARTICLE 1 JAPAN - According to this article 1. The Japanese use 'manufacturing as a competitive weapon'. What do you think 'competitive weapon' means? Explain briefly 2. What other sorts of competitive weapons' can you list that exist today in our firms and industries 3. The table at the end of the Japan article shows inventory levels have tended to be lower in Japan than in the US at that time. List 4 ways from the article to show how that helped the Japanese to lower their costs. -briefly explain to make the connection clear. 4. Highlight in the text of the article evidence of Division of Labor' and upload/ or type the texts you identify by quoting between S. Circle the best answer: According to the article, Japan could sell its cars for $1500 lower compared to the US. mostly due to: a Cheaper labor b. Use of automation c Low absenteeism d. Managing systems e. Economies of scale 6. Support your answer in '6' by listing evidence from the text - at least 3: 7. Quote one example form the text of the Jidoka system "....." then show graphically the effect on one of the Productivity Curves we studied in this chapter. B. ARTICLE No 2: Bloomberg B.Week, "Farewell to Good Times and Nespresso Below are changes mentioned in the article that will affect the cost of operations in Big mining companies. For each question, state the cost component to be affected first (MC?VC?FC?) and WHY. Then show graphically the effects of the change on the all short cost curves together (like we did in class) A brief explanation is required to make your connections clear. (otherwise, cannot evaluate). Label everything Graph in spaces provided (a) BHP Billiton, the world's biggest mining company trimmed about $3.4 billion in costs through such changes as refueling trucks on site in mining pits to avoid wear and tear on expensive tires from driving to faraway fuel stations, (b) Rio Tinto, another major mining company) with $ 50 billion in revenue worked hard to save as little as $60,000 by reducing its servings of hot meat pies and sausages rolls they used to offer their employees. They were quoted as saying "Every pie counts!" C. COMPARING ARTICLE 1 (JAPAN WITH ARTICLE on 3M For questions 1-3 you will be asked to make notations on the text where appropriate. So, print, do the Markings on the article, and upload (or take picture and upload if need to ) If you cannot print the article, then number the paragraphs (there are 13) and list the text by" quoting" and specify which concept this refers to. You MUST mention the paragraph so I can easily locate it. 1.. Circle in the text 6 factors that could cause the MP of their workers to change. Also write in the margin "MP next to the text as an annotation. 2. In the text underline (single line) 3 factors that caused their VC to change. Annotate beside the text by writing "VC" in the margins. 3. In the text put double lines under 4 factors that caused the Fixed Costs of the company to change and annotate in the margin beside the text "FC" 4. What would you say is 3 M's "competitive weapon" and how did that help reduce the company's costs? Write 10 lines using 4 technical terms related to costs. Use additional writing space. 5. Culture does matter, even in the business world!! How different are employee relations in the US form the ones described in Japan? To answer consider the company 3M as a representative of US Corporate world and supply answers to the following (add more writing space) (0 Find/write between quotations three (3) examples from 3M. (11) For each, comment by comparing and contrasting with what happens in Japan. ARTICLE #1 - JAPAN AS A CASE STUDY CAN AMERICAN FIRMS COMPETE The 1980s were a very bruising decade for many American manufacturers. Whereas 20 years ago. American firms were regarded, both here and abroad, as models of efficiency, they have been twit- ted recently of growing lat and lazy. As Business Week put it, "While the Japanese were developing remarkably higher standards for a whole host of products, from consumer electronics to cars and ma- chine tools, many U.S. managers were smugly doz- ing at the switch. As evidence, the critics point to the fact that plants in the United States have been having a very difficult time producing goods of com- parable quality at as low cost as their foreign rivals. To illustrate consider the important cac of auto- mobiles. According to the National Research Council, the Japanese could produce a small car and ship it to the United States at an overall cost that was 5700-S1500 below the production cost of American producers. Obviosly this is an enormous differ- ence. Moreover, the Japanese cars tended to be of higher quality. Even in 1987, after american firms had taken numerous steps to improve quality, the number of prolems reported by owners of new cars was about 35 percent greater for american than Japanese cars. The following is a brief summary of the reasons for this Japanese cos and quality advantage, accord- ing to an influential report by the Naional Research Council: Material control system is the concept of "just in time production. Often called "Kanban" (after the produc- tion cards or tickets used to trigger production), the sys- tem is designed so that materials, parts, and components used at a given step in production are pro- duced or delivered just before they are needed. Thus, stages in the process (including suppliers)are tightly coupled with very little work-in-process inventory. Suppliers must therefore make frequent deliveries of parts, and lot sizes must be small to accommodate product Variety. It is the Japanese view that reduction of decoupling Inventory exposes the real problemas-waste of time! and materials, imbalance in operations, delective parts, equipment operating improperly, and so fonh (The uble on the facing pagel provides comparative data on inventory levels. These data show that dramatically less inventory is used by Japanese firms in the production of automobiles. This is true whether one looks at the pro- cess as a whole or a specific plants.) With smaller buffer stocks the production system will simply not work if there are frequent or lengthy breakdowns. Thus, the just-in-time approach exposes opportunities for reducing waste and solving problems. while at the same time creating pressure for maximizing uptime and minimizing defects. Maintenance programs, preventive and scheduled, are therefore pursued vigor ously. Plants operate with only wo shifts, and equip- Popular accounts of the emergence of Japanese pro- ducers as first-rate, worldwide competitors tend to em phasize the impaa of new automation technology (es. robotics), strong support of the central goverment Ge, Japan, Inc."), and influence of Japanese culture Ge, a dedicated work force). There is no doubt that these factors have played some role. Yet, it is our views that the sources of the Japanese advantage are not to be found in such factors. Rather, they are rooted in a com- mitment to manufacturing excellence and a strategy that uses manufacturing as a competitive weapon The key to Japan's lead... appears to be the inter- action of the material control system, inaintenance prace tices and employee involvement. The key to the The Push for Quality. Butins e June 1917. p.131. ibid. p. 139. have playforce). There Japanese 156 COST ANALYSIS (CH. 6] 3 days ZAO Drill. 24 2031 7 79 $942. $5843 ment is maintained during nonproduction time. The re- sult is a much lower rate of machine failure and break Inventory Comparisons-U.S. and Japan down.. Pressure for defect elimination is reflected in rela- LEVEL/PROCESS JAJAN UNITED STATES Lionships with suppliers and in work pracuces on the line. Just in time production does not allow for exten- 1. Plant and Process sive inspection of incoming parts. Suppliers must, Inventories Assembly plont therefore, achieve highly demanding quality levels, component invenlories consistently and reliably. The major Japanese manufac (equivalent units of turers work closely with outside vendors to make sure production) that responsibility for quality is fele and acted upon at.. 1 hour 5 days the source of product. This same approach-quality Radiolors hours Sdoys control at the source is used in production on the Brake drums 1.5 hours line, where workers have the authority to stop the oper Front-wheel drive transfer auon if they spor defects or other production problems. cose in process ports Waker-initiated line stops are central to the concept of storage by operation Jidoka: making problems visible to everyone's cyc and number of parts) stopping the line-If trouble occurs all thoughts, meth- ods, and tools to avoid stops are Jidoka... .. Ream and chamlar 13 The basic thrust of the Kanban system and the con- 196 Drill cept of Jidoka are to climinate wast, expose problems, Mill, washer, test 10 . and conserve resources. This is not simply a different Assemble 6 *98 . technique of controlling production, but a very differeat . 87* Filish : way of managing the production process. It is clear that Total 1054 . . these systems interact with other factors in our list of 2. Company inventories productivity determinants. Separating their effects from Pa vehicle the effects of quality systems and job structure for ex M918 goz #5215 . ample, is somewhat arbitrary. The Kanban Jidoka sys- 1980 tem uses fewer inspectors and its success requires Work in Progress broader and deeper jobs. . .40.0 12. Indeed, it appears that job structure plays an impr- 1980 6 13.4 tant role in explaining observed productivity different UPO tials. We have already noted two features of the 38 Definodis cost of goods sold vided by workin Japanese system (ouaintenance practices and Jidoka) in which jobs are designed to involve workers in a variety i of tasks. The effects of structure and the differences in management style and practices that go with it (fewer . layers of management, more managing from the bottom up), extend to other aspects of production. Quality air- therefore that in concert with different systems of pro des or "small group involvement activities deal with duction management and control, the work force plays such questions as layout, process methods, and au- a central role in the Japanese competitive advantage. tomation. Such involvement appears to be an important Ebicos in obtaining relatives i etkinliment and motivation..... .. The nature of worker-management relations In Japan is further suggested by much lower levels of unexcused absence than that found in the United States.... In general, absenteeism influences costs, not only through redundant labor but also through fringe costs of the absent group as well as indirect cliccts such as scrap. : reduced learning, and so forth. It appears that absen- tecism may actually account for as much as 10-12 per.. cent of the cost gap. . ... Od is dear that workforce management must be a significant factor in explaining the Japanese cost ad. vantage. Likewise, an atempt to explain quality differ ences would certainly accord a major influence to the work force and its management. It seems evident, 1979 Poss incloric . . National Research Council, The Japanese Cost and Quality Advantage [an] I WSi april 20?, 2002 IN THE LEAD By CAROL HYMOWITZ How Leader at 3M Got His Employees To Back Big Changes THERE TXTILE MR. MCNERNEY 535 YY talked about return investment and the use of best practices across diverse busi- nesses, 3M managers, accustomed to free rein in running their departments, talked about commercializing new Inventions. De- termined to find a common language with middle management, Mr. McNerey took 15 2002 Dow Jones Company, Inc. All Rights Re top executives to a two-day, off-site meeting to reformulate 3M's core values. Their list included phrases such as "chart the course, "energize and inspire others and "deliver results." He set an ambitious goal of increasing sales and operating earnings by at least 10% each year-nearly twice the rate of the past decade. But he resisted barking orders and set about trying to win the hearts and minds of employees. You can't order change," he says. After all, there's only one of me and 75,000 of them.- Mr. Burgstaller says about the numerous meetings with employees: Jim doesn't say. "You've got to do this. Instead he says. 3M has this tremendous reputation and global presence and great technology, and I see all these opportunities we can leverage if we get on the same page and help each other.' Since Mr. McNerey's arrival, 3M has be NO MATTER HOW Intelligent a leader's pun pooling supply purchases on a global ba- sis to get lower prices, and shifted some I stratery for change, it will fail without .. manufacturing to lower cost sites abroad. the dedicated support of the rank and file He also asked 334 managers to rank on a Winning that support often requires more ef- curve every employee reporting to them-a fort than devising the strategy itsell System long used at GE but which backfired W. James McNerney Jr., chief executive at Ford under former CEO Jacques Nasser. of 3M Co., has learned this lesson. Eighteen months ago, when he took over the manufac M R. MCNERNEY AND his top lieuten. turing company that makes everything from L1 ants had to gain acceptance for the Scotch tape to fly fishing gear and pharma new grading system. They reminded employ. ceuticals, 3M's sales were anemic and it ces that in past surveys they had com hadn't launched a blockbuster product in plained that underperformers were too pro- several years. Mr. MeNerey, an 18-year vet. iected at the company. For example, all eran of General Electric who had been in managers above a certain level at 3M were the race to succeed granted stock options each year. Now, op Jack Welch, goldly tions will be granted only to those with bet shook things up with ter-than-average performance grades. 334 one tactic alter an- other from the GE . had a tendency to overvalue experience and undervalue leadership," says Mr. McNerney management book. He pared costs, Aggressive your employees applaud the cut the work force new system. In the past, they had to prove themselves in a series of narrowly defined by almost 10% and Sobs. Now, they are encouraged to step out introduced Slx Sigma, the process . of their niches, and even leapfrog veteran employees. management system that breaks down ev- It has been a difficult balancing act: boosting growth through cost cutting, acqui- ery task into incre sitions, and concentration on leading prod- ments measured ucts and big markets, but preserving 3M's against a perfect model. hallmark creativity. The company's top-notch engineers used Mr. McNemey, the first outsider to rin 3M in its 100-year history, soon found that to be left alone-with ample funding-to do . what was routine at GE was allen at 3M, He" research. Today, top executives specify was the only one who showed up at meet- where RD money is spent. Over the next several years, the company will likely ings without a tie. His blunt and probine shrink its list of 50,000 products to the most questions, rapid speech and Insistence on seeing lots of financial data before making profitable. decisions Jolted many 3M managers. 3M people wake up every morning think This is a homegrown place with a colle ing about what new product they can bring atmosphere where the emphasis on be to market," says Mr. MeNerey. "Innovation in nice to each other means issues haven't is in their DNA-and i ll that entrepre- always surfaced in an honest way." says , neurial spirit I will have failed. My job is to build on that strength, corral and focus it." Bob Bursa Mer, senior vice president of business development and corporate ser Vices, and a 31-year vetetan of M. Brail comments to inteleads.com. To see other recent columns, go to Career Jour mol.com. Inventory Comparisons--U.S. ond Japan LEVEV PROCESS JAAN UNITED STATES 1. Plant and Process Inventories Assembly plant component inventories (equivalent units of production) Hoolers Radiolors Broke drums Front wheel drive transfer cose in process ports storage by operation (number of parts) Mar 1 hour days 2 hours Sdays 1.5 hours 3 days 220 Dr. Ream and chamla Drill Mill, washer, test Assemble Fish Total 2. Company inventories Pa vehick 1919 1980 Work in Progress 1979 1980 STU . 12.) 46 33.9 Definodis cost of goods sold Poss incularis