Question: Answer Question 1 & 2 751 Chapter 16. Lean Systems 16-11. Universal Motors installed a mixed model assembly line at c. Explain how the sequence

Answer Question 1 & 2

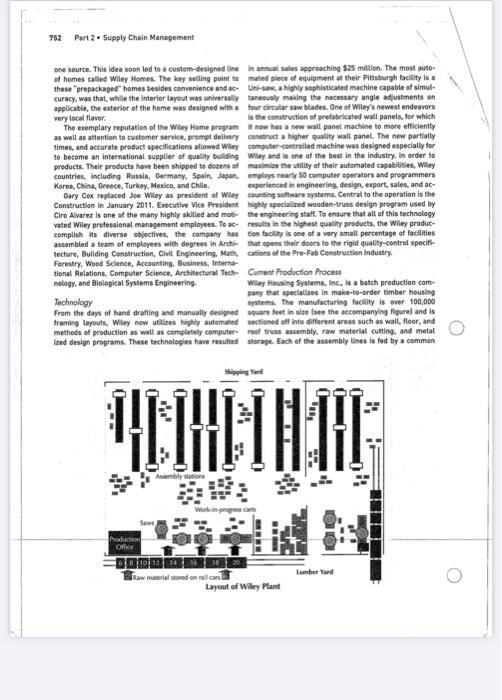

751 Chapter 16. Lean Systems 16-11. Universal Motors installed a mixed model assembly line at c. Explain how the sequence you propose allows quicker its Hantville plant lait year when demand for SUV's adjustments to demand changes. What impact does it still strong. With the rising pas prices, however, SUV have compose demand? sales have plummeted, and demand for smaller more fuel 16-12 Solvo produces three types of trucks on one sembly line: efficient car has urged. The plant has the capacity to pro- the long-haul (L) the short-haul () and the vocational truck doce 200 vehicles per day, Monthly demand for otrs is (V). Next month the company has orders for 500 long-haul estimated at 2000 per month, as 1000 per month and trucks, 750 short-haul truck und 250 vocational tracks SUV: 500 per month. The plant is operating a slow Chris Riggs, the production manager for Solve, wants to try down schedule of 20 days per month uniform production and mixed model sequencing Assuming . Design a production sequence that will meet demand and 25 working days per month, what asembly sequence would level production of the varios models you recommend and how many times per day should the How many times will that que be repeated per day? se be repeated CASE PROBLEM 16.1. The Butz is on the previous day and suggest Improvements to be tried Tina Rosal had been preparing for her company's first out on the third day. This is when Tina would have to prod kalten blitt and wondered if she had thought of every the team to take action to transform the process or the thing. The process they had chosen to kalten had been layout, to improve quality or safety to make a change the subject of numerous customer complaints and em. and analyze the results. On day four, the team would ob- ployee grumblings. Thna's List of reported problems, serve the new process in action, review cycle times, iden goals for the kairen process, and team objectives were tily problems, and make adjustments. After agreeing on stated in the team charter . Tina had planned for the group the parameters of the new process, the team would to review the charter first, then tour the process, mea record their kalzen results by drawing standard operation sure overall cycle time, and complete a process map sheets, training operators, and establishing visual con- From there the team would break up into four subgroups trotools to perform a muda walk and 55 scan, conduct gripe in All those things in one week. Tina was ready and anx- terviews, and analyse process flow. Tina provided forms lous to begin. for each activity and a digital camera for visually docu Take Tina's challenge and perform a kaizen blitzat menting the current process and future Improvements. your school or work. The second day of the blitz was less directed. Team members would regroup to go over the data collected in CASE PROBLEM 16.2. Where's My Cart? 22,300 square feet, on a 60-acre site near the Monong- The Senior Seminar at Alfonso State requires students to hela River in Pittsburgh, Pennsylvania. Utilization of this complete a process Improvement project with local indusspace has never been difficult, and in the fall of 2000 Wiley try. Jim Davis and Leanna Hearn have been assigned to proudly opened a new 6000-square-foot showroom, which Wiley Construction. Here is their report. serves as an educational building center and showcase for many of the products it builds and/or sils. In addition to Wiley Construction its core roof truss business, Wiley now has over 200 em- ployees designing and building for truss systems and Company History preconstructed interior and exterior wall systems. Founded in 1975, Wiley Construction was one of the first Joseph Wiley, the founder and chairman of Wiley Con designers and builders of wooden roof trusses. Over the struction not only wanted to build superior roofing sys- past 40 years Wiley has prospered, and it now has office tems, he also envisioned the idea of prepackaging an and manufacturing space of approximately 132,200 square entire house. The package of materials, from foundation feet and additional tumber storage facilities of about blocks to roofing shingles, would be wailable through (Continued 752 Part 2 Supply Chain Management one source. This idea soon led to a custom-designed line in annual sales approaching $25 million. The most auto- of homes called Wiley Homes. The key selling point tomated piece of equipment at their Pittsburgh facility is a these "prepackaged homes besides convenience and ac-Uni-sw, a highly sophisticated machine capable of simul curacy, was that, while the Interior layout was universally truly making the necessary angle adjustments on applicable, the exterior of the home was designed with a four circular saw blades. One of Wiley's newest endeavors very local flavor. is the construction of prefabricated wall panels, for which The exemplary reputation of the Wiley Home programit now has a ww wall panel machine to more efficiently as well as attention to customer service, prompt delivery construct a higher quality wall panel. The new partially times, and accurate product specifications allowed Wiley computer-controlled machine was designed especially for to become an international supplier of quality building Wiley and is one of the best in the Industry. In order to products. Their products have been shipped to one of the utility of their automated capabilities, Wiley countries, including Russia, Germany, Spain, Japan employs nearly 50 computer operators and programmers Korea, China, Greece, Turkey, Mexico, and Chile. experienced in engineering, design, export, sales, and ac- Gary Cox replaced Joe Wiley as president of Wiley counting software systems. Central to the operation is the Construction in January 2011. Executive Vice President highly specialized wooden-truss design program used by Ciro Alvarez is one of the many highly skilled and mos the engineering staff. To ensure that all of this technology vated Wiley professional management employees. To ac results in the highest quality products, the Wiley produc complish its diverse objectives, the company has on telty is one of a very small percentage of facilities assembled a team of employees with degrees in Arch that opens their doors to the rigid quality control specifi- tecture, Building Construction, Civil Engineering, Mathtations of the Pre-Fab Construction Industry. Forestry, Wood Science, Accounting Business, Interne tional Relations, Computer Science, Architectural Tech Current Production Process nology, and Biological Systems Engineering Wilay Housing Systems, Inc. is a batch production com pany that specializes in make-to-order timber housing Technology systems. The manufacturing facility is over 100.000 From the days of hand drafting and manually designed square feet in size see the accompanying figure and is traming layouts, Wiley now tires Nighly automated sectioned off into different areas such as wallfloor, and methods of production as well as completely computer roof truss assembly, raw material cutting, and metal sed design programs. These technologies have resulted storage. Each of the assembly lines is led by a common DI Assembly station Work Production Office lis w we stored on nalan Layout of Wiley Plant 1 of 1 Chapter 16. Lean Systems 753 26,000 square foot on-site supply point. The only required cart for that job. Mr. Alvarez mentioned that locating the materials are common-sized lumber lie, 2 x 4,2 x 6,cart required for the next job could take anywhere from etc.), aluminum connecting plates, and nails. However, one to ten minutes depending on the assembly backup each of the processes is tailored to meet customer de- Inumber of full carts used that day, and the location of the mands and specifications, cart within the facility. The manufacturing employees are All of Wiley's products are constructed of standard di- tracked on a 100th of the hour time basis for work, which mensional lumber that arrives via truck or train and is means that there should, in theory, be very little unpro- stockpiled in its tumber yard. Typically, Wiley has enough ductive time during the day, with the exception of break lumber on site for two weeks of continuous operation with periods. This also reduces socialization of employees. out replenishment. All other inventory, work-in-process, We decided to narrow our analysis to the immediate and common materials are stored inside the production fa- problem of locating the correct cart. After brainstorming cility. Once an order is received, the staff engineers design possible solutions, we have concluded that Wiley should the truss system and electronically cue the order for manu- use an electronic paging system similar to that restau- facture. The production foreman then assigns the order to a rants use to notify customers that their table is ready. We cutting team. This team consists of two men--the sawer recommend that the carts be outfitted with long-life, and the tailor. The sawer is responsible for saw setup, as durable, and replaceable lithium battery-powered strobe well as lumber retrieval and optimization, while the tailor tights that are activated by a keypad located on the plant stacks and labels the cut lumber for assembly. Mr. Alvarez control office wall beside the pending job order bins. explained that his major concern was the amount of setup Each light would have a unique three-digit number as- time required by the cutting teams. He said that up to 45% signed to it. These numbers would be handwritten on the of production time was spent adjusting the saws for each work order, by the individual who loads the cart, before it job, a very typical problem in batch production. This is is given to the plant supervisor to be assigned. There is a where Wiley's problem and our challenge began. chance of multiple carts being needed for the same job, but each cart has its own individual work order and Process Improvement therefore would have its own three-digit identification After our initial plant tour, where we noted the large number and light. This is no deviation from the current amount of work-in-process inventory waiting in carts be process. The assembly workers would walk to the plant tween the saws and the assembly stations, we spent a day control office, retrieve their next job from the bin, type Interviewing workers on the assembly teams. It was the three-digit code into the keypad, and then find the brought to our attention that at certain points during the cart that has the strobe light turned on. This process day the backup of WIP carts was in fact problematic, from would eliminate all of the guessing currently required to the standpoint of worker safety and from the ability to lo- locate the cart with the raw materials and should reduce cate the required cart quickly and easily. There are approx- the overall average time needed to locate a cart. This imately 80 to 90 carts in use at any given time, which are would also allow for remote storage of the carts, rather loaded with raw materials on a per-job basis and are than stacking as many as 30 carts at the top of the tagged with a work order. After the carts are loaded and assembly Line, a hindrance to traffic flow and safety. tagged, they are placed in front of the assembly worksta- tions. Copies of the work orders are taken to the plant con- Identify waste in the current production process. trol office. The plant supervisor then assigns the jobs to How does the pager suggestion eliminate waste? assembly stations by placing the work order copy in as- Have the students and Mr. Alvarez found the root signed bins located on the plant control office wall. The cause of the cart problem? why or why not? assembly employees will go to their assigned bin, pick 4. How would you apply the principles of lean produc- th next job ticket, and then locate the corresponding tion to improve Wiley's situation