Question: answer question 2 only pls release this question to other expert , if you can not read it, the pic is 100% clear, this is

answer question 2 only

pls release this question to other expert , if you can not read it, the pic is 100% clear, this is the 3rd time you said the said things, you are wasting my quota.

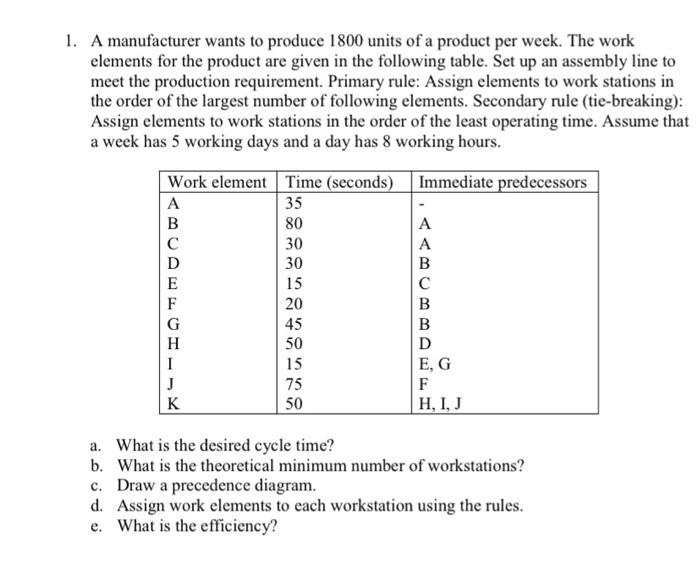

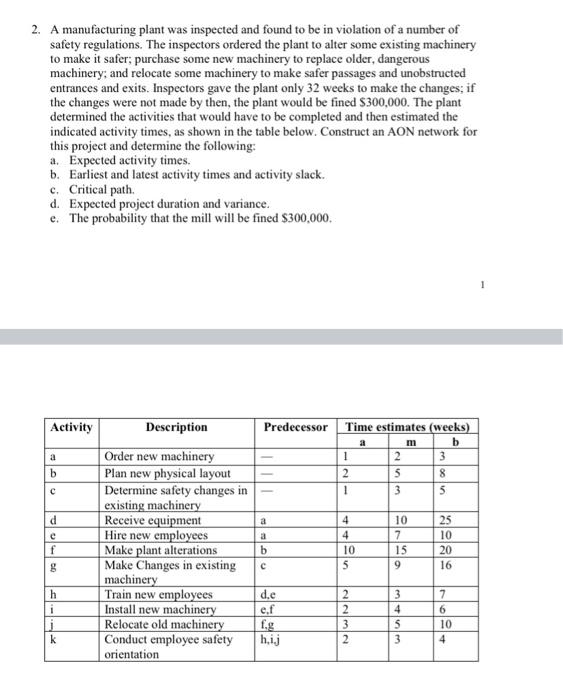

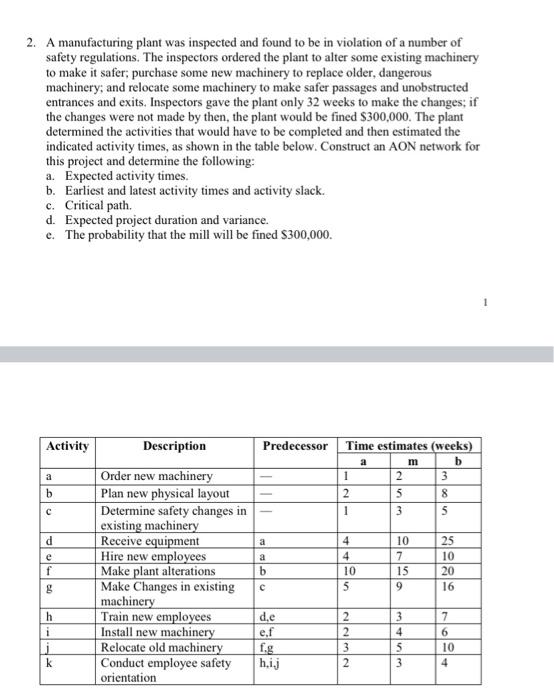

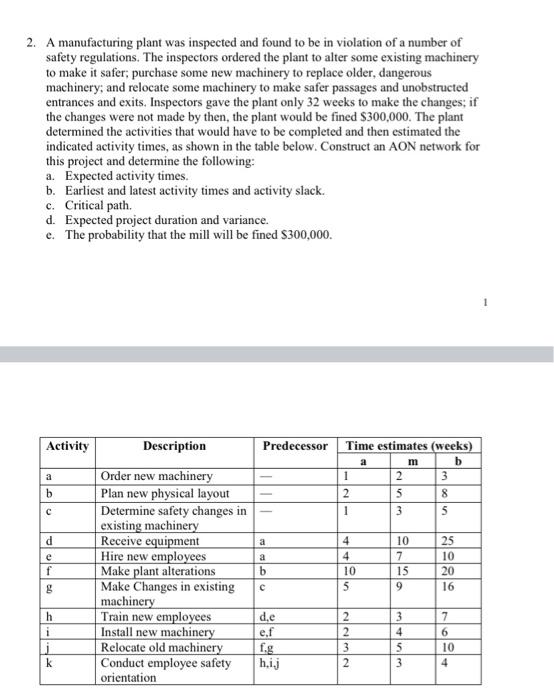

A mufacturer wants to penis of product per week. The work elements for the product are piven in the following the Set phyiiete mert the productie Primaryn Ailementos the order of the latest umber offering met Synule Amig mest to work station in the end of that puting time the weck werking days and a day has working hours Work clemet The Immediate predecem 15 20 45 EG What is the desired cycle time! 6 What is the theoretical minimum numbered workstations Dwa precedence digim 4. Asign work closach wie wing the What the clicy 2 manufacturing plant was inspected and found to be in violation of a number of safety. Tentoondered the planter som sitting machinery to make it safer perhat some new machinery to replace aldes, dan unbed entre els hupetes pee the plant cely 2 weeks to make the change the changes were made by then the plane would be fine. The plan determined the activities that would be completed and the estimate indicated activity times, as shown in the table clow.Centret NON this project and determine the following Expected activity times Earles and activity times and this Critical pathi a Expected project duration and variate The phytut the mill will be 100.00 Activity Description Pruder Tiaries ( 2 13 1 1 1 5 10 Order new many Plan new pical layout Determine safety comes iting maching Receive Hier. | Make Make Chaplin minary Train new comples Instal New machi Relocated machine Cendet employee diety 4 10 15 PI 16 2 de E 7 6 1 2 3 4 15 3 4 Dashboard Calendar To Do Notifications Inbox 1. A manufacturer wants to produce 1800 units of a product per week. The work elements for the product are given in the following table. Set up an assembly line to meet the production requirement. Primary rule: Assign elements to work stations in the order of the largest number of following elements. Secondary rule (tie-breaking): Assign elements to work stations in the order of the least operating time. Assume that a week has 5 working days and a day has 8 working hours. Immediate predecessors Work element Time (seconds) A 35 B 80 30 D 30 E 15 F 20 G 45 H I 15 J 75 K 50 A A B B B D E, G F HIJ 50 a. What is the desired cycle time? b. What is the theoretical minimum number of workstations? c. Draw a precedence diagram. d. Assign work elements to each workstation using the rules. e. What is the efficiency? 2. A manufacturing plant was inspected and found to be in violation of a number of safety regulations. The inspectors ordered the plant to alter some existing machinery to make it safer; purchase some new machinery to replace older, dangerous machinery, and relocate some machinery to make safer passages and unobstructed entrances and exits. Inspectors gave the plant only 32 weeks to make the changes; if the changes were not made by then, the plant would be fined $300,000. The plant determined the activities that would have to be completed and then estimated the indicated activity times, as shown in the table below. Construct an AON network for this project and determine the following: a. Expected activity times. b. Earliest and latest activity times and activity slack. c. Critical path. d. Expected project duration and variance. e. The probability that the mill will be fined $300,000 1 Activity Description a m a Predecessor Time estimates (weeks) b 1 2 3 2 5 8 1 3 5 b a d e f a b 4 4 10 Order new machinery Plan new physical layout Determine safety changes in existing machinery Receive equipment Hire new employees Make plant alterations Make Changes in existing machinery Train new employees Install new machinery Relocate old machinery Conduct employee safety orientation 10 7 15 25 10 20 16 8 lo h i J k de e.f f.g 3 4 2 2 3 2 7 6 10 4 hij 2. A manufacturing plant was inspected and found to be in violation of a number of safety regulations. The inspectors ordered the plant to alter some existing machinery to make it safer, purchase some new machinery to replace older, dangerous machinery; and relocate some machinery to make safer passages and unobstructed entrances and exits. Inspectors gave the plant only 32 weeks to make the changes; if the changes were not made by then, the plant would be fined $300,000. The plant determined the activities that would have to be completed and then estimated the indicated activity times, as shown in the table below. Construct an AON network for this project and determine the following: a. Expected activity times. b. Earliest and latest activity times and activity slack. C. Critical path. d. Expected project duration and variance. e. The probability that the mill will be fined $300,000. Activity Predecessor a Time estimates (weeks) b 1 2 3 2 8 1 3 5 b ly 3 d a e f Description Order new machinery Plan new physical layout Determine safety changes in existing machinery Receive equipment Hire new employees Make plant alterations Make Changes in existing machinery Train new employees Install new machinery Relocate old machinery Conduct employee safety orientation a b 4 4 10 5 10 7 15 9 25 10 20 16 8 h i de e.f f.g hij 2 2 3 2 7 6 10 4 1 k i am going to report this case

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock