Question: Answer questions 5.2, 5.3, 5.4 Q5.2 (Simple Setup) Consider the following batch flow process consisting of three process steps performed by three machines: Batch of

Answer questions 5.2, 5.3, 5.4

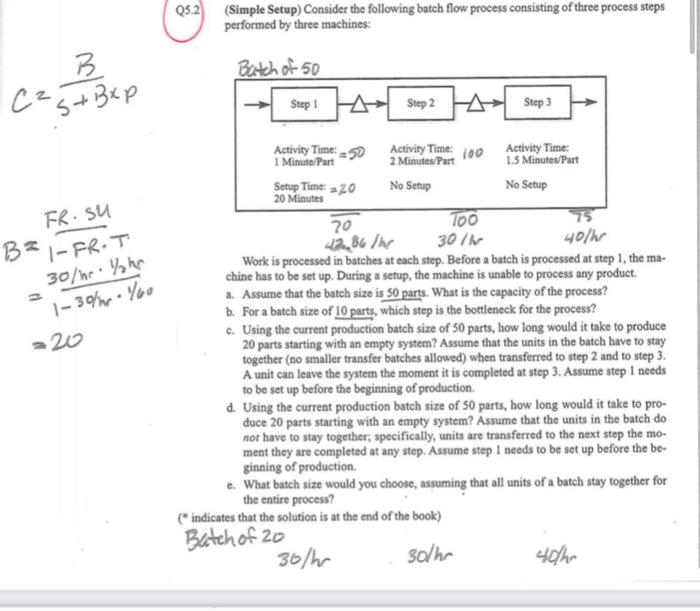

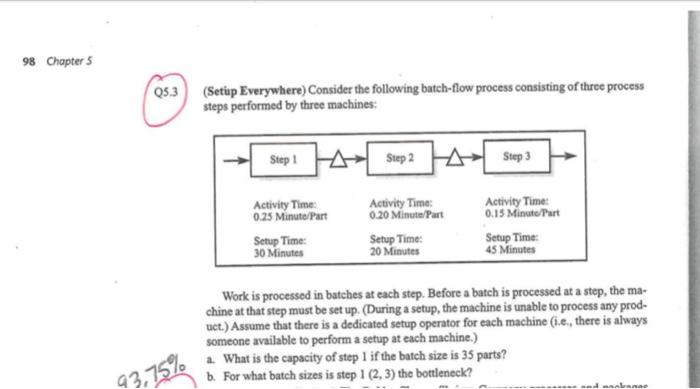

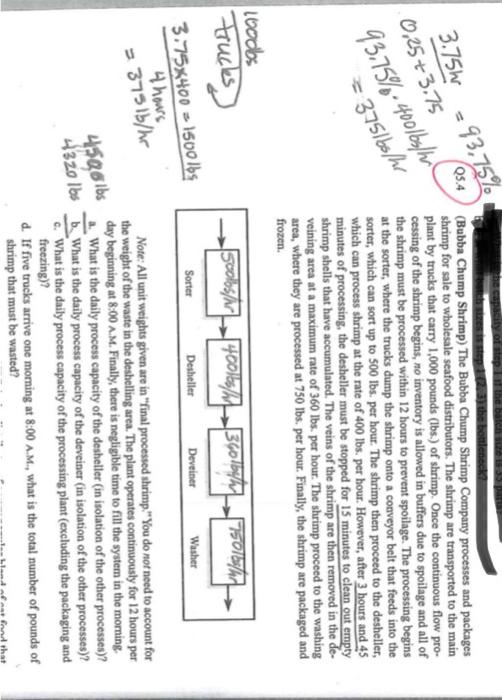

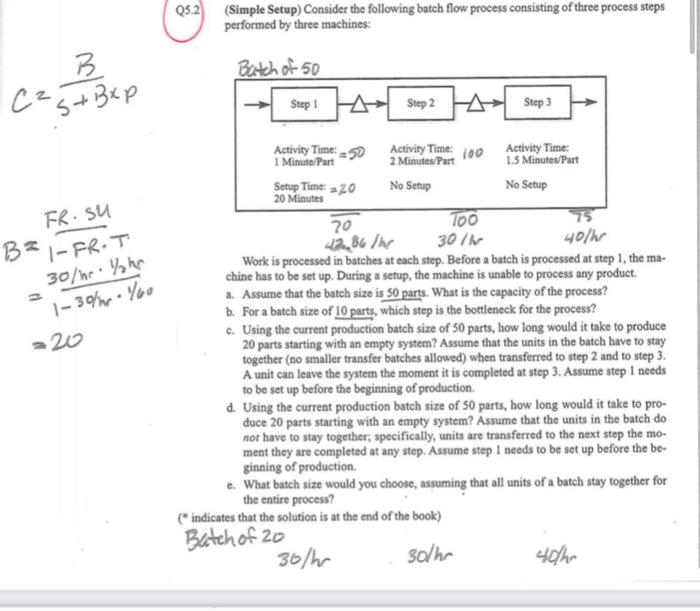

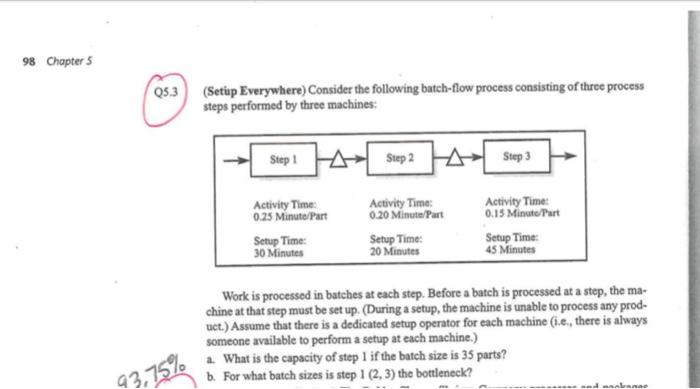

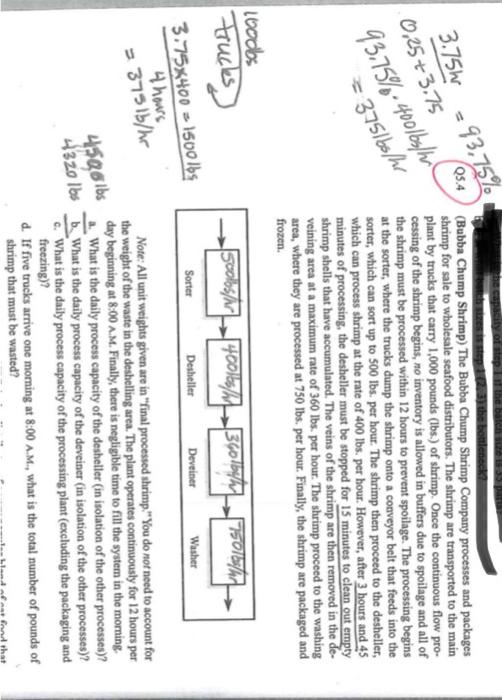

Q5.2 (Simple Setup) Consider the following batch flow process consisting of three process steps performed by three machines: Batch of 50 B B C5+ Bxp Step 1 Step 2 Step 3 FR.SU 1 30e.hr 1-30/ /60 - 20 Activity Time: Activity Time: Activity Time: 1 Minute/Part 100 2 Minutes/Part 1.5 Minutes/Part Setup Time: 20 No Setup No Setup 20 Minutes 20 100 42,86 The 30/1 40/hr Work is processed in batches at each step. Before a batch is processed at step 1, the ma- chine has to be set up. During a setup, the machine is unable to process any product. 2. Assume that the batch size is 50 parts. What is the capacity of the process? d. For a batch size of 10 parts, which step is the bottleneck for the process? c. Using the current production batch size of 50 parts, how long would it take to produce 20 parts starting with an empty system? Assume that the units in the batch have to stay together (no smaller transfer batches allowed) when transferred to step 2 and to step 3. A unit can leave the system the moment it is completed at step 3. Assume step 1 needs to be set up before the beginning of production d. Using the current production batch size of 50 parts, how long would it take to pro- duce 20 parts starting with an empty system? Assume that the units in the batch do not have to stay together, specifically, units are transferred to the next step the mo- ment they are completed at any step. Assume step I needs to be set up before the be- ginning of production e. What batch size would you choose, assuming that all units of a batch stay together for the entire process? (indicates that the solution is at the end of the book) Batch of 2o 30/h 30/hr 40/h 98 Chapter 5 Q5.3 (Setup Everywhere) Consider the following batch-flow process consisting of three process steps performed by three machines Step 1 Step 2 Step 3 Activity Time: 0.25 Minute/Part Setup Time: 30 Minutes Activity Time: 0.20 Minute/Part Setup Time: 20 Minutes Activity Time: 0.15 Minuto/Part Setup Time: 45 Minutes Work is processed in batches at each step. Before a batch is processed at a step, the ma- chine at that step must be set up (During a setup, the machine is unable to process any prod- uct.) Assume that there is a dedicated setup operator for each machine (i.c., there is always someone available to perform a setup at each machine.) a. What is the capacity of step 1 if the batch size is 35 parts? b. For what batch sizes is step 1 (2, 3) the bottleneck? 93,75% 25.4 3.75h -93,75% 0,25 +3.75 93,75%-400163/h ze step (Bubba Chump Shrimp) The Bubba Chump Shrimp Company processes and packages shrimp for sale to wholesale seafood distributors. The shrimp are transported to the main plant by trucks that carry 1,000 pounds (lbs.) of shrimp. Once the continuous flow pro- cessing of the shrimp begins, no inventory is allowed in buffers due to spoilage and all of the shrimp must be processed within 12 hours to prevent spoilage. The processing begins at the sorter, where the trucks dump the shrimp onto a conveyor belt that feeds into the sorter, which can sort up to 500 lbs. per hour. The shrimp then proceed to the desheller, which can process shrimp at the rate of 400 lbs. per hour. However, after 3 hours and 45 minutes of processing, the desheller must be stopped for 15 minutes to clean out empty shrimp shells that have accumulated. The veins of the shrimp are then removed in the de- veining area at a maximum rate of 360 lbs. per hour. The shrimp proceed to the washing area, where they are processed at 750 lbs. per hour. Finally, the shrimp are packaged and frozen. = 3751bolhi looobs Trucks -500star400lesh 3Golbeth 750lbs Desheller Sorter Washer Deveiner 3.75x400 1500 lbs 4 hours - 3751b/he 4526 lbs Note: All unit weights given are in "final processed shrimp." You do not need to account for the weight of the waste in the deshelling area. The plant operates continuously for 12 hours per day beginning at 8:00 AM. Finally, there is negligible time to fill the system in the morning. What is the daily process capacity of the desheller (in isolation of the other processes)? 3320 16 What is the daily process capacity of the deveiner (in isolation of the other processes)? 6. What is the daily process capacity of the processing plant (excluding the packaging and freezing)? d. If five trucks arrive one morning at 8:00 A.M., what is the total number of pounds of shrimp that must be wasted? ward that

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock