Question: Answer questions 9 , 1 0 and 1 1 based on the case and data given in the following: An industrial engineer applies work sampling

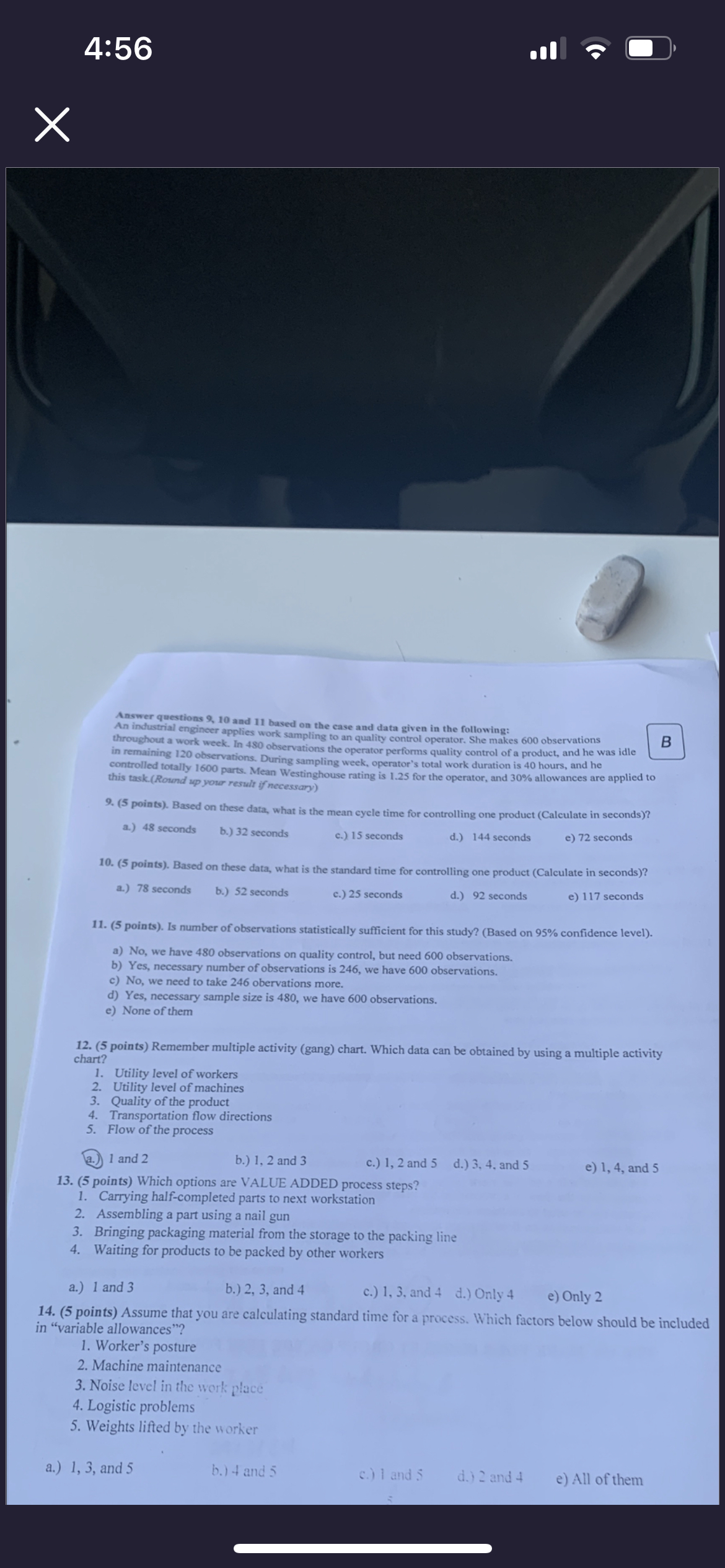

Answer questions and based on the case and data given in the following: An industrial engineer applies work sampling to an quality control operator. She makes observations throughout a work week. In observations the operator performs quality control of a product, and he was idle in remaining observations. During sampling week, operator's total work duration is hours, and he controlled totally parts. Mean Westinghouse rating is for the operator, and allowances are applied to this task. Round up your result if necessary

points Based on these data, what is the mean cycle time for controlling one product Calculate in seconds

a seconds

b seconds

c seconds

d seconds

e seconds

:

Answer questions and based on the case and data given in the following: An industrial engincer applies work sampling to an quality control operator. She makes observations in remaining obseek. In observations the operator performs quality control of a product, and he was idle controlled totally pare. Muring sampling week, operator's total work duration is hours, and he

points Based on these data, what is the mean cycle time for controlling one product Calculate in seconds

a seconds

b seconds

c seconds

d seconds

e seconds

points Based on these data, what is the standard time for controlling one product Calculate in seconds

a seconds

b seconds

c seconds

d seconds

e seconds

points Is number of observations statistically sufficient for this study? Based on confidence level

a No we have observations on quality control, but need observations:

b Yes, necessary number of observations is we have observations.

c No we need to take obervations more.

d Yes, necessary sample size is we have observations.

e None of them

points Remember multiple activity gang chart. Which data can be obtained by using a multiple activity chart?

Utility level of workers

Utility level of machines

Quality of the product

Transportation flow directions

Flow of the process

a and

b and

c and

d and

e and

points Which options are VALUE ADDED process steps?

Carrying halfcompleted parts to next workstation

Assembling a part using a nail gun

Bringing packaging material from the storage to the packing line

Waiting for products to be packed by other workers

a and

b and

c and

d Only

e Only

points Assume that you are calculating standard time for a process. Which factors below should be included in "variable allowances"?

Worker's posture

Machine maintenance

Noise level in the work place

Logistic problems

Weights lifted by the worker

a and

b and

c and

d and

e All of them

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock