Question: Answer The below question from case studies. 1. The steps involved in the construction CPM diagram are Choose as many as applies (Choose 3 steps)

Answer The below question from case studies.

1. The steps involved in the construction CPM diagram are Choose as many as applies (Choose 3 steps)

A. Assign relationships

B. List activities

C. Estimate duration

D. Calculate the duration of CPM path

E. list of critical activities

F. Assign float

2. Which team was responsible for execution of project activities?

A. Manufacturing specialists

B. Middle managers from functional departments

C. Core project team

D. First tier team

3. What is the difference between CPM and PERT

A. CPM uses certain activity durations, whereas PERT uses uncertain duration estimates

B. CPM uses uncertain activity durations, whereas PERT uses certain duration estimates

C. CPM uses probabilistic activity durations, whereas PERT uses deterministic duration estimates

4. How will use prepare/extract a two week look ahead schedule for each team member?

A. I will split the activities to shorter duration, assign staff, and then extract activities that fall in next two weeks

B. I will assign staff, and then extract activities from the schedule that falls in next two weeks

C. The execution team will pick up their activities and I will prepare a GANTT chart for them

5. Which statement describes best the company situation

A. The core team with little PM training

B. No external PM consultant

C. Lack of formal PM structure and little to no PM knowledge

D. Conflict between core team and execution team

6. What was the solution presented in the case?

A. extract two weeks lookahead activities for each team member

B. a short-term outlook schedule for the entire project

C. CPM diagram for two-week activities

D. GANTT chart for the entire project

7. From Figure 6.5, what is the project critical path?

A. ACEFGH

B. ABEFGH

C. ACDGH

8. The case study "Atlascom" discusses about (Specific)

A. Project scheduling

B. CPM for scheduling

C. Critical Activities

D. Non of them

9. The Critical Path Method can be used (Choose the most appropriate answer)

A. to predict project duration and least flexible activities

B. to identify activities with zero float

C. to identify critical activities

D. to identify project duration and flexible activities

10. Which team was responsible to manage project activities?

A. Manufacturing specialists

B. Middle managers from functional departments

C. Second tier team

D. Top management

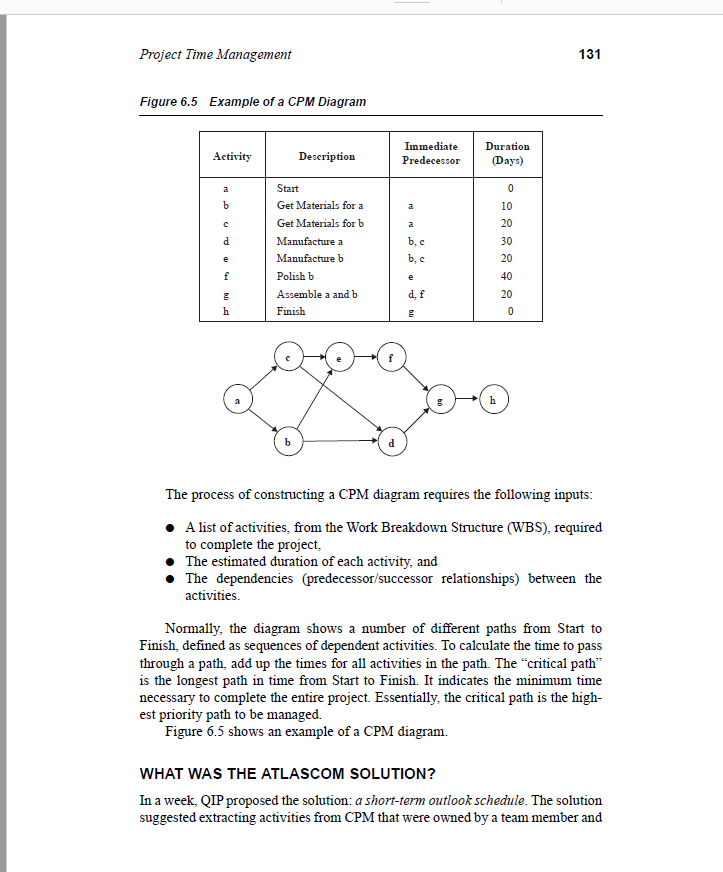

Atlas Com Dragan Z. Milosevic, Peerasit Patanakul, and Sabin Srivannaboon In its 50+ year history, Atlas Com has excelled in manufacturing state-of-the-art specialized construction equipment. Recently, management has noticed that manufacturing productivity and quality has been falling behind the competitors. In response, several projects were launched, one of which was to focus on reengi- neering the factory layout. Management tasked a two-tier team to get the job done. The first tier was the core project team, a cross-functional group of middle managers responsible for managing the project effort. The second tier, the extended team of manufacturing specialists, was in charge of doing the project work. Faced with the lack of a formal project management process and experience, the core team received basic project management training before hiring a consultant who helped develop a detailed CPM schedule. Gearing to launch the execution, the core team explained the CPM schedule to the extended team members, ask- ing them to get the work started and to report progress in a week. The problem was, the extended team members commented that because of CPM's complexity, they were not able to use it as a basis for planning, organizing and reporting. A few days later, a quality improvement project (QIP) including members from both teams was chartered to find a solution to the problem. WHAT IS CPM? Developed by the DuPont Corporation in the 1950s. Critical Path Method (CPM) is a network diagram technique for analyzing planning, and scheduling projects. It provides a means of representing project activities as nodes or arrows, deter- mining which of them are "critical in their impact on project completion time and scheduling them in order to meet a target date at a minimum cost. CPM uses deterministic activity time estimates (the most likely), rather than probabilistic activity time estimates (eg., the optimistic, pessimistic, and most likely) such as those used in Program Evaluation and Review Technique (PERT). The typical use of CPM was for construction projects, although it is nowadays applied in many types of projects across various industries. 130 Project Time Management 131 Figure 6.5 Example of a CPM Diagram Activity Description Immediate Predecessor Duration (Days) a 0 b a 10 20 a d Start Get Materials for a Get Materials for b Manufacture a Manufacture b Polish b Assemble a and b Finish bc b, e 30 20 40 f S d. f 20 0 b d The process of constructing a CPM diagram requires the following inputs: A list of activities, from the Work Breakdown Structure (WBS), required to complete the project, The estimated duration of each activity, and The dependencies (predecessor/successor relationships) between the activities. Normally, the diagram shows a number of different paths from start to Finish, defined as sequences of dependent activities. To calculate the time to pass through a path, add up the times for all activities in the path. The "critical path" is the longest path in time from Start to Finish. It indicates the minimum time necessary to complete the entire project. Essentially, the critical path is the high- est priority path to be managed. Figure 6.5 shows an example of a CPM diagram. WHAT WAS THE ATLASCOM SOLUTION? In a week, QIP proposed the solution: a short-term outlook schedule. The solution suggested extracting activities from CPM that were owned by a team member and 132 CASE STUDIES were to be done in the coming two weeks, rather than the entire schedule, presenting them in a Gantt chart format. Familiar with the Gantt chart, each member thus should have a user-friendly two-week plan that they could start using for organ- izing work and reporting and updating on a weekly basisStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts