Question: Page: 130,131,144 Learning Activity #4 Choose an organization to which you presently or have previously belonged (employer, volunteer group, etc.) ( If you don't have

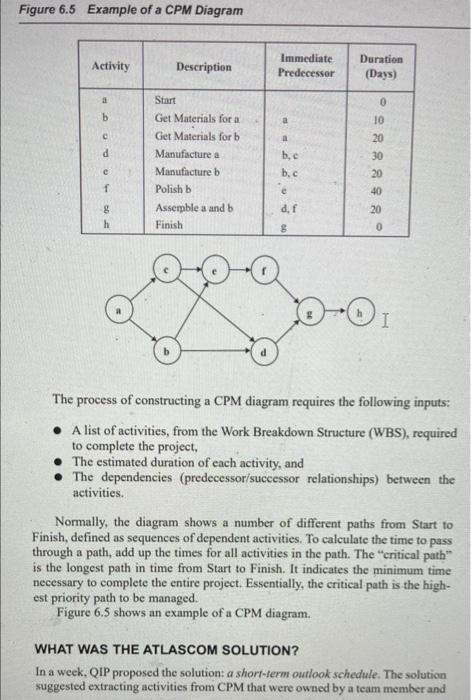

Learning Activity #4 Choose an organization to which you presently or have previously belonged (employer, volunteer group, etc.) ( If you don't have one, select a company of your choice). In the textbook, some strategies are listed on p. 130 and 131, and Porter's 5 generic strategies are listed on p. 144. Do you think they drive decisions? Why? If you were in charge in your company, what changes would you make to the strategic decision and why? In its 50+ year history, Atlas Com has excelled in manufacturing state-of-the-art specialized construction equipment. Recently, management has noticed that manufacturing productivity and quality has been falling behind the competitors. In response, several projects were launched, one of which was to focus on reengi- neering the factory layout. Management tasked a two-tier team to get the job done. The first tier was the core project team, a cross-functional group of middle managers responsible for managing the project effort. The second tier, the extended team of manufacturing specialists, was in charge of doing the project work. Faced with the lack of a formal project management process and experience, the core team received basic project management training before hiring a consultant who helped develop a detailed CPM schedule. Gearing to launch the execution, the core team explained the CPM schedule to the extended team members, ask- ing them to get the work started and to report progress in a week. The problem was, the extended team members commented, that because of CPM's complexity, they were pot able to use it as a basis for planning, organizing, and reporting. A few days later, a quality improvement project (QIP) including members from both teams was chartered to find a solution to the problem. a WHAT IS CPM? a Developed by the DuPont Corporation in the 1950s, Critical Path Method (CPM) is a network diagram technique for analyzing, planning, and scheduling projects. It provides a means of representing project activities as nodes or arrows, deter- mining which of them are "critical" in their impact on project completion time and scheduling them in order to meet a target date at a minimum cost. CPM uses deterministic activity time estimates (the most likely), rather than probabilistic activity time estimates (e.g., the optimistic, pessimistic, and most likely) such as those used in Program Evaluation and Review Technique (PERT). The typical use of CPM was for construction projects, although it is nowadays applied in many types of projects across various industries. 130 Figure 6.5 Example of a CPM Diagram Activity Description Immediate Predecessor Duration (Days) a 0 b a 10 20 c a d b, c Start Get Materials for a Get Materials for b Manufacture a Manufacture b Polish b Assemble a and b Finish eggie e bc 20 1 e d. f 8 h 20 0 8 The process of constructing a CPM diagram requires the following inputs: A list of activities, from the Work Breakdown Structure (WBS), required to complete the project, The estimated duration of ench activity, and The dependencies (predecessor/successor relationships) between the activities. Normally, the diagram shows a number of different paths from Start to Finish, defined as sequences of dependent activities. To calculate the time to pass through a path, add up the times for all activities in the path. The "critical path" is the longest path in time from start to Finish. It indicates the minimum time necessary to complete the entire project. Essentially, the critical path is the high- est priority path to be managed. Figure 6.5 shows an example of a CPM diagram. WHAT WAS THE ATLASCOM SOLUTION? In a week. QIP proposed the solution: a short-term outlook schedule. The solution suggested extracting activities from CPM that were owned by a team member and 144 CASE STUDIES PERFORMANCE MEASUREMENT BASELINE CHANGED Howard met with Mike Thompson to briefly discuss the situation, and then they got on the phone with the vendor responsible for producing the structural parts with the new process. The vendor and Acme agreed to take parts from the last batch produced and cut them into tensile test specimens. The vendor would then subcontract a local test lab to conduct tensile testing of these parts; five speci- mens from each of the six structural parts. Howard then contacted the customer's project manager to inform him of their plans. He answered, That sounds good, but we've been discussing this situation here and we want to get our material and process technology experts involved in this. The schedule and technical risks are too high, and we can't afford failure." After they hung up, Mike and Howard started talking about the impact of the recent developments on the project's financial status. Mike: The vendor isn't going to do this extra work for free you know, and I want our engineering people intimately involved. We can't afford to let the vendor be solely responsible for the success of these tests. The stakes are too high. Howard's mind drifted back to a recent meeting the TPMs had with Ward Robinson: Ward: I'm getting quite a bit of heat from corporate management to keep our earned value metrics near 100 percent. I want to remind you all that your pri- mary responsibility is to keep your project's Schedule and Cost Performance Indices (SPI and CPI) in the 90 to 110 percent range. If you do that, it makes my life a lot easier, and we don't have to spend the time and effort explaining why we're deviating from these goals. Howard continued with Mike: Howard: You know this new effort is all out of scope relative to the project's baseline. Mike: I know it might be, but what choice do we have? If we don't do this, the customer will never accept parts from the new process, and we don't have the time to develop an alternative in time for the first flight of the airplane in August. Besides, meeting our recurring cost targets depends on our being able to use the new process. I do know one thing, though. Developing the new process was definitely in the baselined project; maybe we just did a poor job of estimating the required extent of that effort. Learning Activity #4 Choose an organization to which you presently or have previously belonged (employer, volunteer group, etc.) ( If you don't have one, select a company of your choice). In the textbook, some strategies are listed on p. 130 and 131, and Porter's 5 generic strategies are listed on p. 144. Do you think they drive decisions? Why? If you were in charge in your company, what changes would you make to the strategic decision and why? In its 50+ year history, Atlas Com has excelled in manufacturing state-of-the-art specialized construction equipment. Recently, management has noticed that manufacturing productivity and quality has been falling behind the competitors. In response, several projects were launched, one of which was to focus on reengi- neering the factory layout. Management tasked a two-tier team to get the job done. The first tier was the core project team, a cross-functional group of middle managers responsible for managing the project effort. The second tier, the extended team of manufacturing specialists, was in charge of doing the project work. Faced with the lack of a formal project management process and experience, the core team received basic project management training before hiring a consultant who helped develop a detailed CPM schedule. Gearing to launch the execution, the core team explained the CPM schedule to the extended team members, ask- ing them to get the work started and to report progress in a week. The problem was, the extended team members commented, that because of CPM's complexity, they were pot able to use it as a basis for planning, organizing, and reporting. A few days later, a quality improvement project (QIP) including members from both teams was chartered to find a solution to the problem. a WHAT IS CPM? a Developed by the DuPont Corporation in the 1950s, Critical Path Method (CPM) is a network diagram technique for analyzing, planning, and scheduling projects. It provides a means of representing project activities as nodes or arrows, deter- mining which of them are "critical" in their impact on project completion time and scheduling them in order to meet a target date at a minimum cost. CPM uses deterministic activity time estimates (the most likely), rather than probabilistic activity time estimates (e.g., the optimistic, pessimistic, and most likely) such as those used in Program Evaluation and Review Technique (PERT). The typical use of CPM was for construction projects, although it is nowadays applied in many types of projects across various industries. 130 Figure 6.5 Example of a CPM Diagram Activity Description Immediate Predecessor Duration (Days) a 0 b a 10 20 c a d b, c Start Get Materials for a Get Materials for b Manufacture a Manufacture b Polish b Assemble a and b Finish eggie e bc 20 1 e d. f 8 h 20 0 8 The process of constructing a CPM diagram requires the following inputs: A list of activities, from the Work Breakdown Structure (WBS), required to complete the project, The estimated duration of ench activity, and The dependencies (predecessor/successor relationships) between the activities. Normally, the diagram shows a number of different paths from Start to Finish, defined as sequences of dependent activities. To calculate the time to pass through a path, add up the times for all activities in the path. The "critical path" is the longest path in time from start to Finish. It indicates the minimum time necessary to complete the entire project. Essentially, the critical path is the high- est priority path to be managed. Figure 6.5 shows an example of a CPM diagram. WHAT WAS THE ATLASCOM SOLUTION? In a week. QIP proposed the solution: a short-term outlook schedule. The solution suggested extracting activities from CPM that were owned by a team member and 144 CASE STUDIES PERFORMANCE MEASUREMENT BASELINE CHANGED Howard met with Mike Thompson to briefly discuss the situation, and then they got on the phone with the vendor responsible for producing the structural parts with the new process. The vendor and Acme agreed to take parts from the last batch produced and cut them into tensile test specimens. The vendor would then subcontract a local test lab to conduct tensile testing of these parts; five speci- mens from each of the six structural parts. Howard then contacted the customer's project manager to inform him of their plans. He answered, That sounds good, but we've been discussing this situation here and we want to get our material and process technology experts involved in this. The schedule and technical risks are too high, and we can't afford failure." After they hung up, Mike and Howard started talking about the impact of the recent developments on the project's financial status. Mike: The vendor isn't going to do this extra work for free you know, and I want our engineering people intimately involved. We can't afford to let the vendor be solely responsible for the success of these tests. The stakes are too high. Howard's mind drifted back to a recent meeting the TPMs had with Ward Robinson: Ward: I'm getting quite a bit of heat from corporate management to keep our earned value metrics near 100 percent. I want to remind you all that your pri- mary responsibility is to keep your project's Schedule and Cost Performance Indices (SPI and CPI) in the 90 to 110 percent range. If you do that, it makes my life a lot easier, and we don't have to spend the time and effort explaining why we're deviating from these goals. Howard continued with Mike: Howard: You know this new effort is all out of scope relative to the project's baseline. Mike: I know it might be, but what choice do we have? If we don't do this, the customer will never accept parts from the new process, and we don't have the time to develop an alternative in time for the first flight of the airplane in August. Besides, meeting our recurring cost targets depends on our being able to use the new process. I do know one thing, though. Developing the new process was definitely in the baselined project; maybe we just did a poor job of estimating the required extent of that effort