Question: answer the two discussion questions 1) what are vision systems and why are they a useful OM tool? 2) which od the quality control tools

answer the two discussion questions

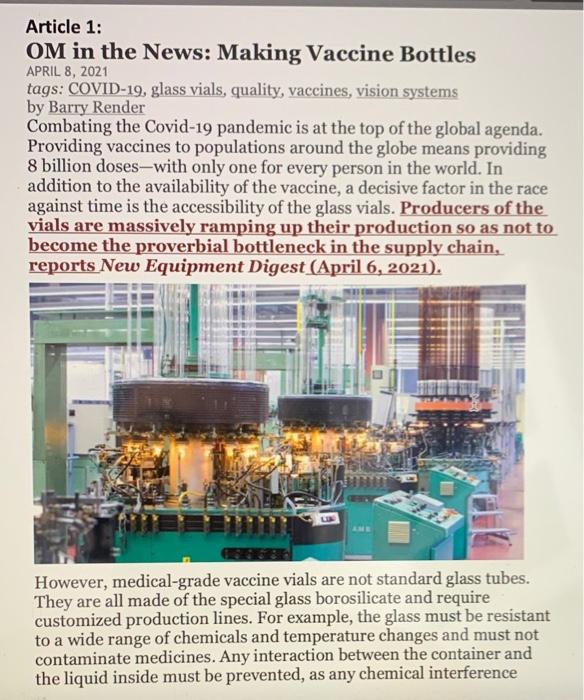

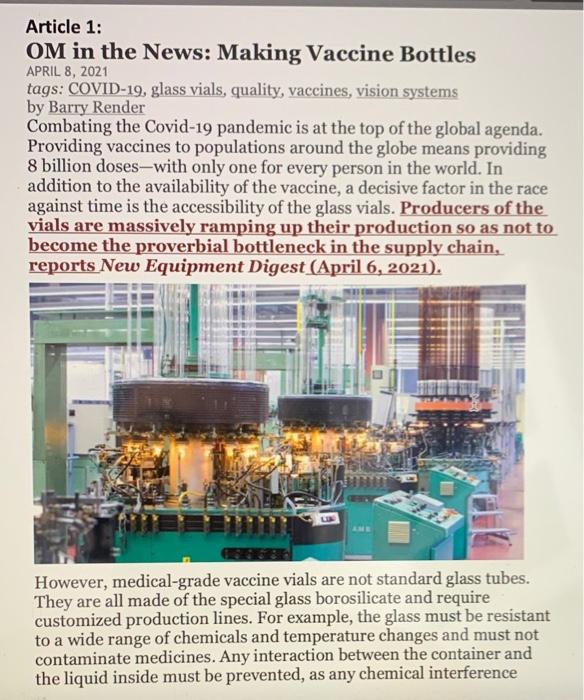

Article 1: OM in the News: Making Vaccine Bottles APRIL 8, 2021 tags: COVID-19, glass vials, quality, vaccines, vision systems by Barry Render Combating the Covid-19 pandemic is at the top of the global agenda. Providing vaccines to populations around the globe means providing 8 billion doses-with only one for every person in the world. In addition to the availability of the vaccine, a decisive factor in the race against time is the accessibility of the glass vials. Producers of the vials are massively ramping up their production so as not to become the proverbial bottleneck in the supply chain, reports New Equipment Digest (April 6, 2021). However, medical-grade vaccine vials are not standard glass tubes. They are all made of the special glass borosilicate and require customized production lines. For example, the glass must be resistant to a wide range of chemicals and temperature changes and must not contaminate medicines. Any interaction between the container and the liquid inside must be prevented, as any chemical interference could affect the vaccine. Even the smallest scratch, crack or fissure can render an entire batch unusable, contaminate the line during the filling process or even lead to a machine standstill. The demands on manufacturers are enormous: it is not only a matter of producing large quantities quickly but also of maintaining particularly high-quality standards. So, what is needed is very fast quality control with high reliability in defect detection. One solution is vision systems. Powerful cameras can capture images of 120 vials per minute to be inspected for dimensional accuracy or surface condition with very high precision. Defects such as cracks, scratches, chips, inclusions, or stains are detected with an accuracy of o.1 square millimeters. Intelligent software enables accurate fault description analysis and classification. Testing takes place at various points in the manufacturing process, such as directly after the bottles have been formed or shortly before packaging. Classroom discussion questions: 1. What are vision systems and why are they a useful OM tool? 2. Which of the quality control tools that you learned could vial producers employ

1) what are vision systems and why are they a useful OM tool?

2) which od the quality control tools that are learned could vial producers employ?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock