Question: answer this question showing the steps 3. (a) A process is in control with x-double-bar = 75 and s-bar = 2. The process specifications are

answer this question showing the steps

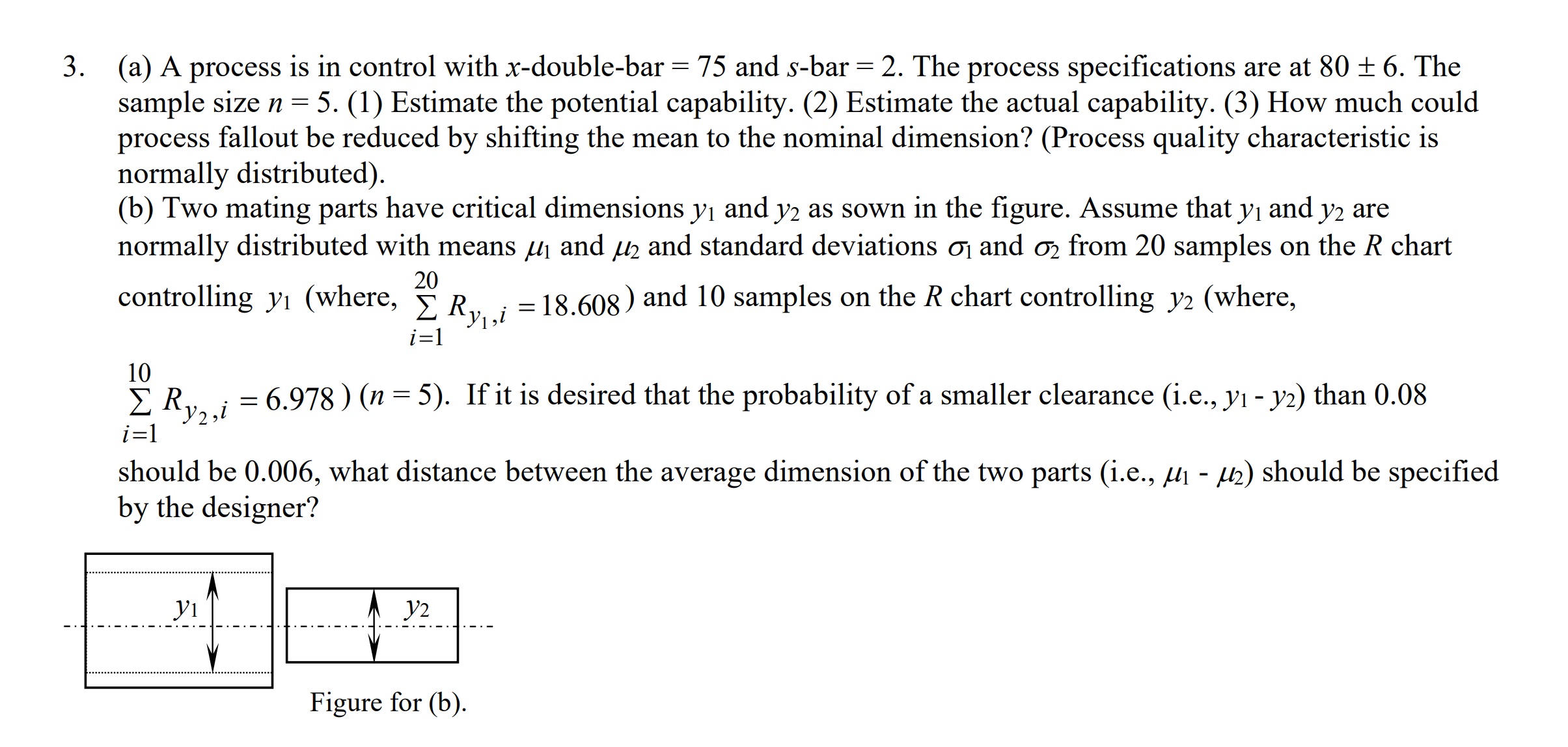

3. (a) A process is in control with x-double-bar = 75 and s-bar = 2. The process specifications are at 80 + 6. The sample size n = 5. (1) Estimate the potential capability. (2) Estimate the actual capability. (3) How much could process fallout be reduced by shifting the mean to the nominal dimension? (Process quality characteristic is normally distributed). (b) Two mating parts have critical dimensions y1 and y2 as sown in the figure. Assume that y, and y2 are normally distributed with means / and /2 and standard deviations o and o2 from 20 samples on the R chart controlling y1 (where, ER,, ; = 18.608 ) and 10 samples on the R chart controlling y2 (where, i= 1 10 [ Ry,.i = 6.978 ) (n =5). If it is desired that the probability of a smaller clearance (i.e., y1 - y2) than 0.08 i=1 should be 0.006, what distance between the average dimension of the two parts (i.e., /1 - /2) should be specified by the designer? V1 V2 Figure for (b)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts