Question: Anyone help me and this question for B and C Mimi's father is the owner of Bitara Engineering in Kuantan and this company is operating

Anyone help me and this question for B and C

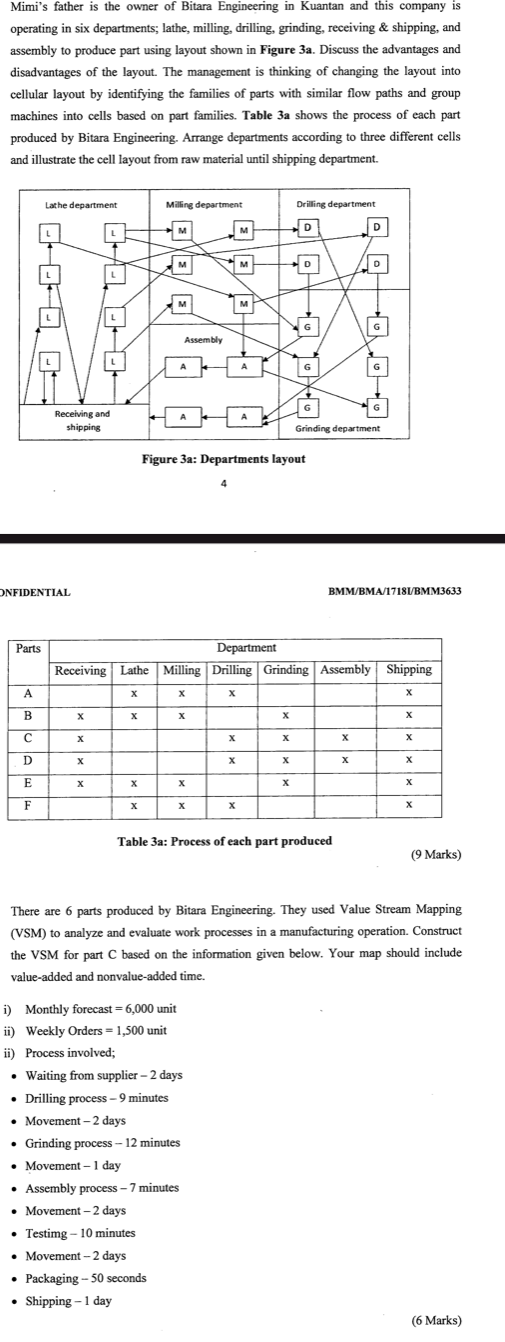

Mimi's father is the owner of Bitara Engineering in Kuantan and this company is operating in six departments; lathe, milling, drilling, grinding, receiving & shipping, and assembly to produce part using layout shown in Figure 3a. Discuss the advantages and disadvantages of the layout. The management is thinking of changing the layout into cellular layout by identifying the families of parts with similar flow paths and group machines into cells based on part families. Table 3a shows the process of each part produced by Bitara Engineering. Arrange departments according to three different cells and illustrate the cell layout from raw material until shipping department. Lathe department Milling department Drilling department M M D D M M D D L M M G Assembly A 6 G Receiving and shipping Ay Grinding department Figure 3a: Departments layout 4 ONFIDENTIAL BMM/BMA/17181/BMM3633 Parts Department Receiving Lathe Milling Drilling Grinding Assembly Shipping A X X X B X D E X F X X X Table 3a: Process of each part produced (9 Marks) There are 6 parts produced by Bitara Engineering. They used Value Stream Mapping (VSM) to analyze and evaluate work processes in a manufacturing operation. Construct the VSM for part C based on the information given below. Your map should include value-added and nonvalue-added time. i) Monthly forecast = 6,000 unit ii) Weekly Orders = 1,500 unit ii) Process involved; Waiting from supplier - 2 days Drilling process - 9 minutes Movement - 2 days Grinding process - 12 minutes Movement - 1 day Assembly process - 7 minutes Movement - 2 days Testimg-10 minutes Movement - 2 days Packaging - 50 seconds Shipping - 1 day (6 Marks) (6 Marks) Mimi's father is the owner of Bitara Engineering in Kuantan and this company is operating in six departments; lathe, milling, drilling, grinding, receiving & shipping, and assembly to produce part using layout shown in Figure 3a. Discuss the advantages and disadvantages of the layout. The management is thinking of changing the layout into cellular layout by identifying the families of parts with similar flow paths and group machines into cells based on part families. Table 3a shows the process of each part produced by Bitara Engineering. Arrange departments according to three different cells and illustrate the cell layout from raw material until shipping department. Lathe department Milling department Drilling department M M D D M M D D L M M G Assembly A 6 G Receiving and shipping Ay Grinding department Figure 3a: Departments layout 4 ONFIDENTIAL BMM/BMA/17181/BMM3633 Parts Department Receiving Lathe Milling Drilling Grinding Assembly Shipping A X X X B X D E X F X X X Table 3a: Process of each part produced (9 Marks) There are 6 parts produced by Bitara Engineering. They used Value Stream Mapping (VSM) to analyze and evaluate work processes in a manufacturing operation. Construct the VSM for part C based on the information given below. Your map should include value-added and nonvalue-added time. i) Monthly forecast = 6,000 unit ii) Weekly Orders = 1,500 unit ii) Process involved; Waiting from supplier - 2 days Drilling process - 9 minutes Movement - 2 days Grinding process - 12 minutes Movement - 1 day Assembly process - 7 minutes Movement - 2 days Testimg-10 minutes Movement - 2 days Packaging - 50 seconds Shipping - 1 day (6 Marks) (6 Marks)Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock