Question: >> Apple: The Best Supply Chains in the World? For eight straight years, Apple has been recognized as having the best worldwide supply chains in

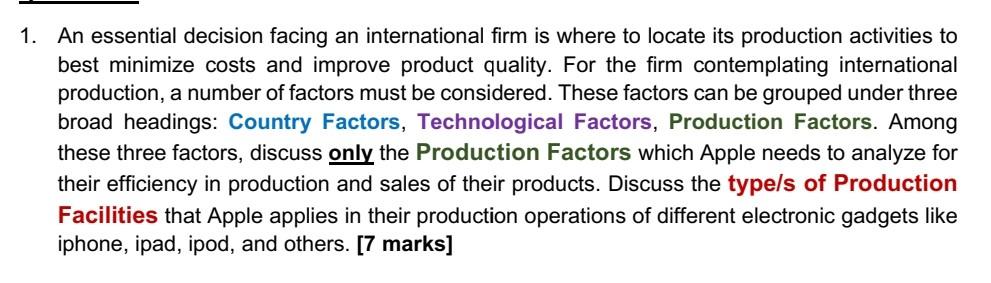

>> Apple: The Best Supply Chains in the World? For eight straight years, Apple has been recognized as having the best worldwide supply chains in the "Gartner Global Supply Chain Top 25" ranking. In the most recent ranking, Apple was actually classified above the ranking as a "Master" (Amazon.com was the listed the number one company). The Master status recognizes the accomplishments and capabilities of long- term global supply chain leaders in the Gartner Global Supply Chain Top 25. Companies qualify for the Masters category if their score places them in the top five rankings for at least seven out of the past 10 years. Numerous honors have also been made about Apple's supply chain strategy, operations, and results. For example, Apple's supply chains "best demonstrate leadership in applying demand-driven principles to drive business results." "Apple dominates because it consistently brings both operational and innovation excellence to bear in some of the most competitive markets in the world." Basically, Apple gets a lot of credit in the supply chain profession for being able to increase volumes both in hardware and software while also uniquely helping redefine the consumer electronics market (e.g., iPhone, iPad, MacBook). Apple is the world's second-largest information technology company by revenue after Samsung and the second- largest mobile phone producer also after Samsung. In Interbrand's Best Global Brands report, Apple is now also the most valuable brand in the world. It overtook Coca-Cola in 2013 for the number one position after Coca- Cola's 13-year run at the top and has stayed at the top every year since that time. Apple has an estimated brand value of more than $170 billion. "Few brands have enabled so many people to do so much so easily, which is why Apple has legions of adoring fans." These "fans" or customers have downloaded apps for Apple's electronic gadgets more than 60 billion times. The company's general supply chain model follows the path of most large multinational corporations' supply chains. They do research and DO development to cultivate new technologies and/or to acquire intellectual property needed for future products. They test the product concepts via marketing research, product testing, and total cost analysis. After that, Apple typically does a prelaunch of new products, where global production, sourcing commitments, inventory management, and so on are evaluated. The product launch involves doing demand forecasts, resolving potential backlogs, and ensuring that the products are in the hands of its customers in as fast a cycle time as possible. After the launch, monitoring starts with periodic reviews of inventory, demand, life cycle status, and component cost forecasts. A number of factors make Apple's global supply chains world leading. First, early on, Apple took steps to manage the total value created in its global supply chains by managing its suppliers and all other providers within the chains. Predetermined expectations of suppliers, exclusivity in supplier arrangements, and volume guarantees ensured a supply chain infrastructure that could support Apple's aggressive market leadership. Apple's relationship building with its network partners is also a strength that has helped with increased scaling of production and resulted in improved quality in the manufacturing processes. Plus, and not to be underestimated, Apple has accumulated lots of cash! The available cash funds have partially been used to place high-volume orders, which strengthen supplier relationships, and in other ways maintain global supply chain leadership. Using its supply chain infrastructure, Apple has managed to solve most of the challenges it has faced. For example, while the global economic downturn in 2008 presented problems for virtually all companies, Apple came through it in great shape. At the time, CEO Steve Jobs said, "We're armed with the strongest product line in our history, the most talented employees and the best customers in our industry. Apple just reported one of the best quarters in its history." Other challenges that Apple is facing include obtaining enough quality components for its consumer electronics, potential for supply chain disruptions (natural and people created), dependence on third- party logistics providers, and inventory management issues. In each case, so far, Apple has strategically solved major issues to the satisfaction of the marketplace (the company consistently ranks at the top in "customer satisfaction" in the American Customer Satisfaction Index). Warehousing United Warehouses via Online Store Retail China Stores Elk Grove Other Asian Direct Sales Force Retailers However, everything is not all glowing or positive about Apple. The company's reputation has taken a few hits recently. For example, Apple was found guilty by a U.S. court of conspiring with publishers Sourcing Manufacturing Distribution Return to set the price of e-books that were bought using Intermediate iTunes. The ongoing dispute with Samsung States regarding various patents keeps lingering year-by- UPS/Fedex Warranty year, and worldwide customers are almost Return Warehouse fanatically taking sides for or against Apple. There Assembly in Facility in Trade in Program have also been allegations about the treatment of China California Recycle Reuse employees at Foxconn in China (one of the Apple Countries Program suppliers). Plus, there was a U.S. Senate hearing Wholesalers, that investigated Apple's "highly questionable" tax Europe Network minimization strategies. Now, on the more positive side, Apple has a portfolio of potential blockbuster products, welcomed upgrades, and innovative services in the making that are sure to remind its fans why they favor Apple products. The challenges attached to these new offerings are sure to test Apple's leadership in both brand value and best global supply chains. To some degree, the future challenges are clear. To stay at the top of its industry, Apple has to succeed in slowing Samsung's momentum and capturing the booming Chinese mobile phone market. As always with Apple, as set in our expectations over the years by Steve Jobs's "one more thing" announcements, CEO Tim Cook and the new Apple leadership team must keep communicating to the market that their vision, innovations, and leadership can drive the idea that Apple's best days are ahead. As one way to do this, Apple is on a hiring binge in Asia, adding hundreds of engineers and supply chain managers to its staff in Shanghai and Taipei as it seeks to increase the speed at which it introduces new products. Plus, with Cook as the CEO, Apple has a global production and supply chain management expert at the helm who constantly scrutinizes Apple's supply chains, production operations, and fair labor practices. Carriers 1. An essential decision facing an international firm is where to locate its production activities to best minimize costs and improve product quality. For the firm contemplating international production, a number of factors must be considered. These factors can be grouped under three broad headings: Country Factors, Technological Factors, Production Factors. Among these three factors, discuss only the Production Factors which Apple needs to analyze for their efficiency in production and sales of their products. Discuss the typels of Production Facilities that Apple applies in their production operations of different electronic gadgets like iphone, ipad, ipod, and others. [7 marks]

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock