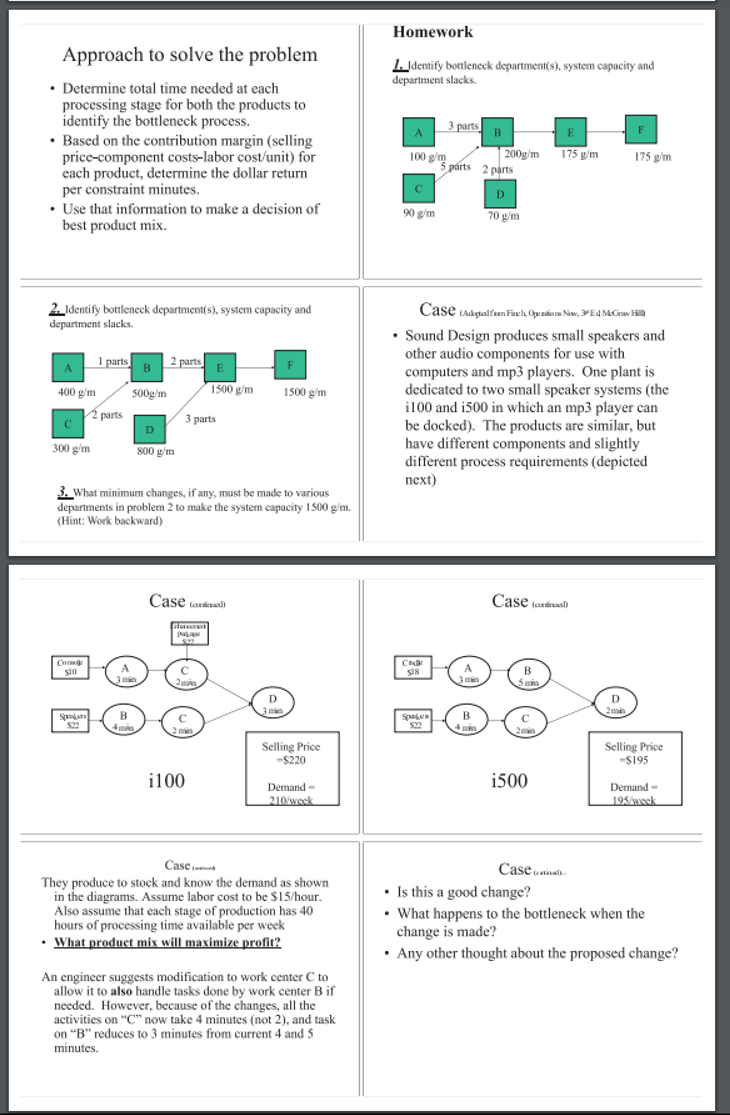

Question: Approach to solve the problem Determine total time needed at each processing stage for both the products to identify the bottleneck process. Based on the

Approach to solve the problem

Determine total time needed at each

processing stage for both the products to

identify the bottleneck process.

Based on the contribution margin selling

pricecomponent costslabor costunit for

each product, determine the dollar return

per constraint minutes.

Use that information to make a decision of

best product mix.

Homework

LIdentify bottleneck departments system capacity and

department slacks.

Identify bottleneck departments system capacity and

department slacks.

What minimum changes, if any, must be made to various

departments in problem to make the system capacity

Hint: Work backward

Case

Sound Design produces small speakers and

other audio components for use with

computers and mp players. One plant is

dedicated to two small speaker systems the

i and i in which an mp player can

be docked The products are similar, but

have different components and slightly

different process requirements depicted

next

They produce to stock and know the demand as shown

in the diagrams. Assume labor cost to be $ hour.

Also assume that each stage of production has

hours of processing time available per week

What product mix will maximize prefit?

An engineer suggests modification to work center to

allow it to also handle tasks done by work center B if

needed. However, because of the changes, all the

activities on C now take minutes not and task

on reduces to minutes from current and

minutes.

Case

Is this a good change?

What happens to the bottleneck when the

change is made?

Any other thought about the proposed change?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock