Question: ArcSite Electrical, which produces generators, purchases a component that is used in its generators directly from the supplier. The generator production operation requires a constant

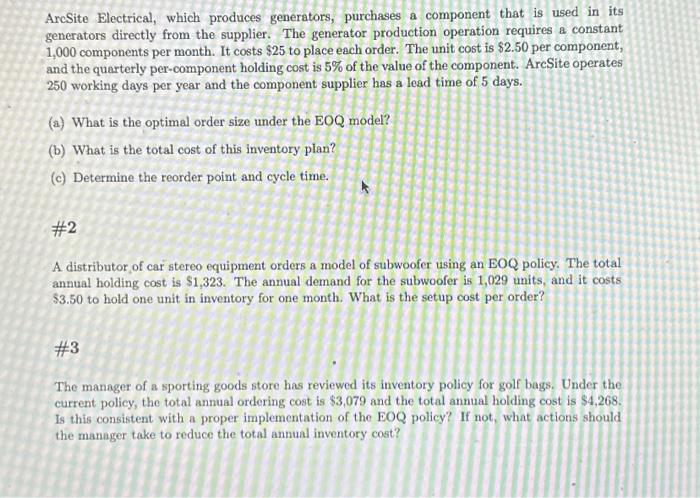

ArcSite Electrical, which produces generators, purchases a component that is used in its generators directly from the supplier. The generator production operation requires a constant 1,000 components per month. It costs $25 to place each order. The unit cost is $2.50 per component, and the quarterly per-component holding cost is 5% of the value of the component. ArcSite operates 250 working days per year and the component supplier has a lead time of 5 days. (a) What is the optimal order size under the EOQ model? (b) What is the total cost of this inventory plan? (c) Determine the reorder point and cycle time. #2 A distributor of car stereo equipment orders a model of subwoofer using an EOQ policy. The total annual holding cost is $1,323. The annual demand for the subwoofer is 1,029 units, and it costs $3.50 to hold one unit in inventory for one month. What is the setup cost per order? #3 The manager of a sporting goods store has reviewed its inventory policy for golf bags. Under the current policy, the total annual ordering cost is $3,079 and the total annual holding cost is $4,268. Is this consistent with a proper implementation of the EOQ policy? If not, what actions should the manager take to reduce the total annual inventory cost

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts