Question: ASAP = = Design a loose-type flange with a plain face for a reactor shell with 1.9 m outside diameter and 0.018 thickness (go). Other

ASAP

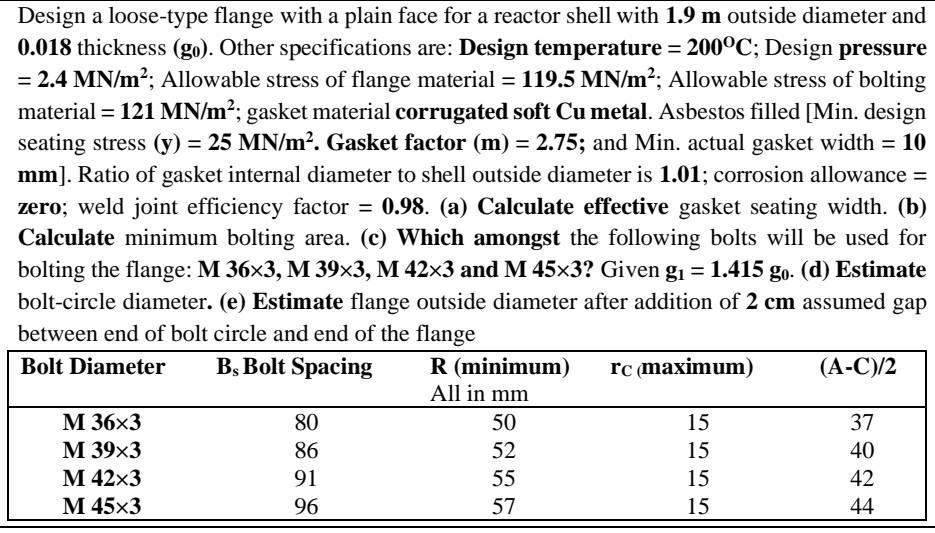

= = Design a loose-type flange with a plain face for a reactor shell with 1.9 m outside diameter and 0.018 thickness (go). Other specifications are: Design temperature = 200C; Design pressure = 2.4 MN/m; Allowable stress of flange material = 119.5 MN/m; Allowable stress of bolting material = 121 MN/m; gasket material corrugated soft Cu metal. Asbestos filled [Min. design seating stress (y) = 25 MN/m. Gasket factor (m) = 2.75; and Min. actual gasket width = 10 mm). Ratio of gasket internal diameter to shell outside diameter is 1.01; corrosion allowance = zero; weld joint efficiency factor = 0.98. (a) Calculate effective gasket seating width. (b) Calculate minimum bolting area. (c) Which amongst the following bolts will be used for bolting the flange: M 36x3, M 39x3, M 42x3 and M 45x3? Given g = 1.415 go. (d) Estimate bolt-circle diameter. (e) Estimate flange outside diameter after addition of 2 cm assumed gap between end of bolt circle and end of the flange Bolt Diameter BBolt Spacing R (minimum) rc (maximum) (A-C)/2 All in mm M 36x3 80 50 15 37 M 39x3 86 52 15 40 M 42x3 91 55 15 42 M 45x3 96 57 15 44 = = Design a loose-type flange with a plain face for a reactor shell with 1.9 m outside diameter and 0.018 thickness (go). Other specifications are: Design temperature = 200C; Design pressure = 2.4 MN/m; Allowable stress of flange material = 119.5 MN/m; Allowable stress of bolting material = 121 MN/m; gasket material corrugated soft Cu metal. Asbestos filled [Min. design seating stress (y) = 25 MN/m. Gasket factor (m) = 2.75; and Min. actual gasket width = 10 mm). Ratio of gasket internal diameter to shell outside diameter is 1.01; corrosion allowance = zero; weld joint efficiency factor = 0.98. (a) Calculate effective gasket seating width. (b) Calculate minimum bolting area. (c) Which amongst the following bolts will be used for bolting the flange: M 36x3, M 39x3, M 42x3 and M 45x3? Given g = 1.415 go. (d) Estimate bolt-circle diameter. (e) Estimate flange outside diameter after addition of 2 cm assumed gap between end of bolt circle and end of the flange Bolt Diameter BBolt Spacing R (minimum) rc (maximum) (A-C)/2 All in mm M 36x3 80 50 15 37 M 39x3 86 52 15 40 M 42x3 91 55 15 42 M 45x3 96 57 15 44

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts