Question: Produce a work breakdown structure for the minor dwelling project plan ( the image files provided) using ms word or another software. The work breakdown

Produce a work breakdown structure for the minor dwelling project plan ( the image files provided) using ms word or another software. The work breakdown structure should have 4 hierarchy levels with 40-45 activities. it is expected that you may wish to consider: infrastructure; substructure; super-structure; internal trades (including services & finishes); external works, but not limited to these categories.

Use this work breakdown structure to create a logically linked network (precedence chart) for the construction of the project. Select an appropriate scale and produce a network chart derived from the network, using MS Project or similar software. The start date for the project shall be to be the first working Monday after your Birthday this year (2020). Adopt NZ industry standard holidays (Christmas, Easter, ANZAC day etc.).

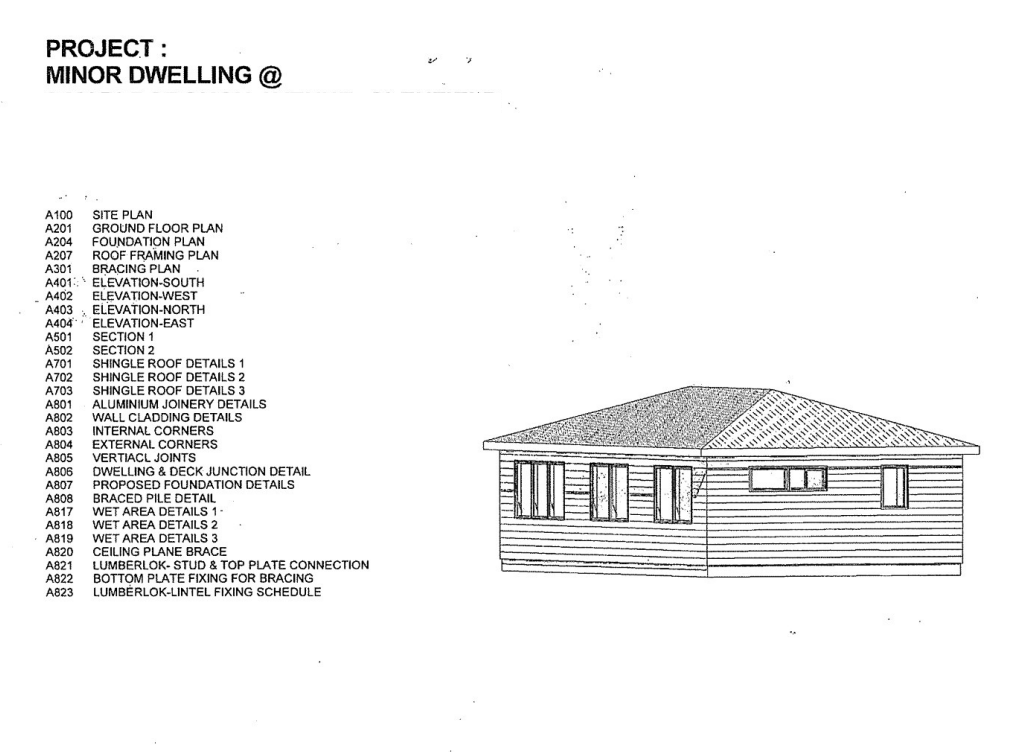

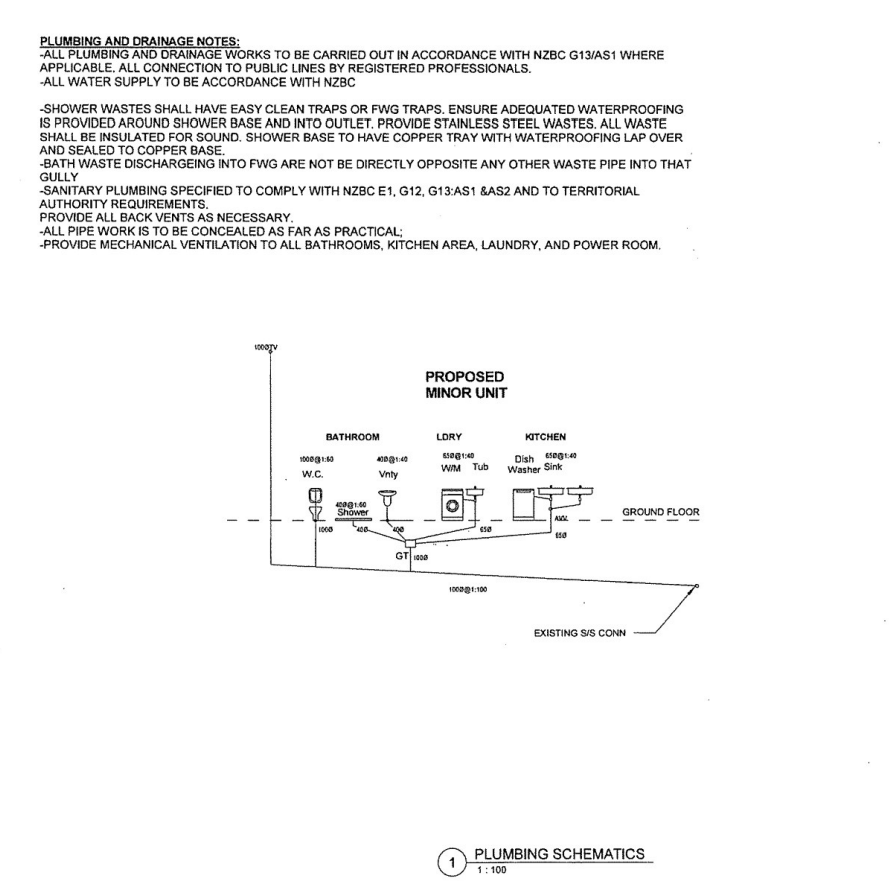

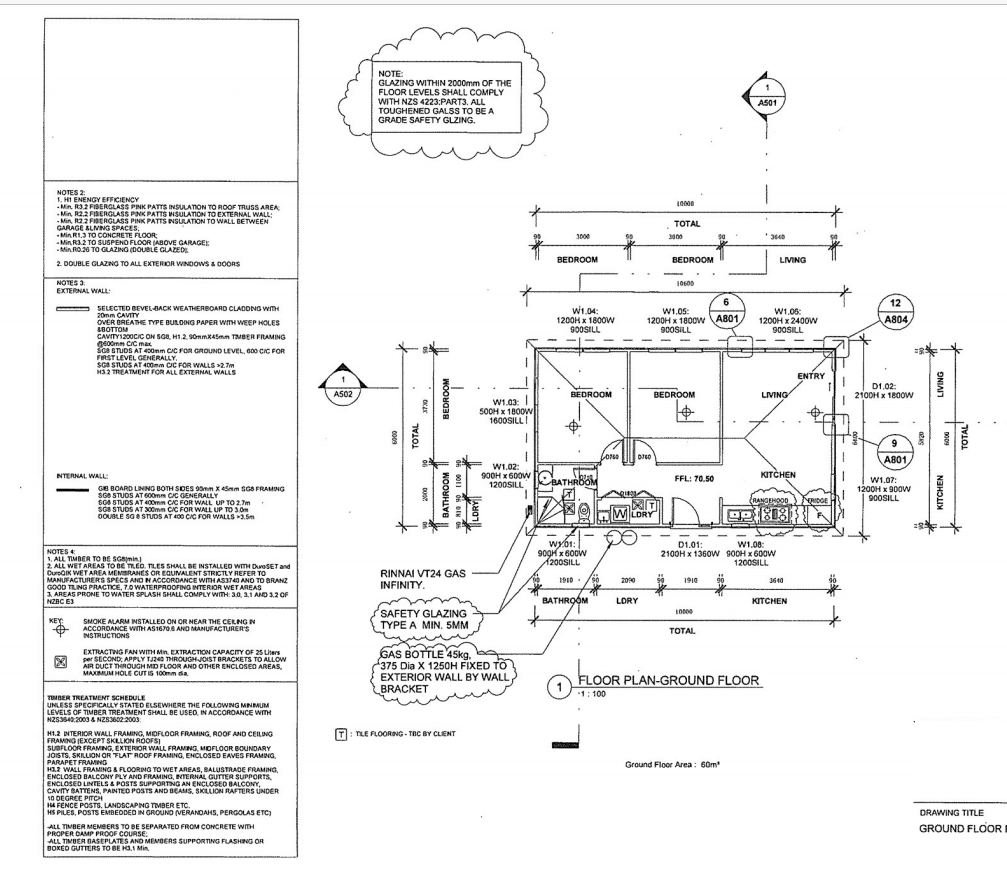

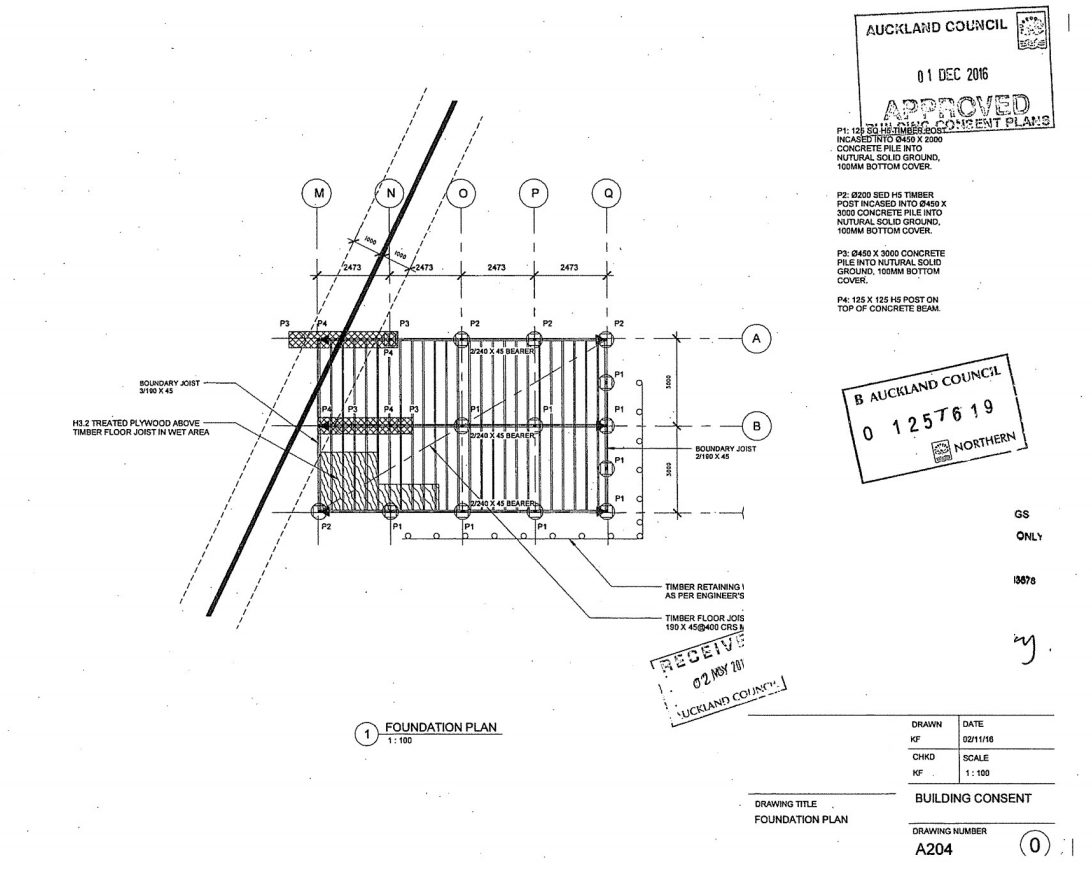

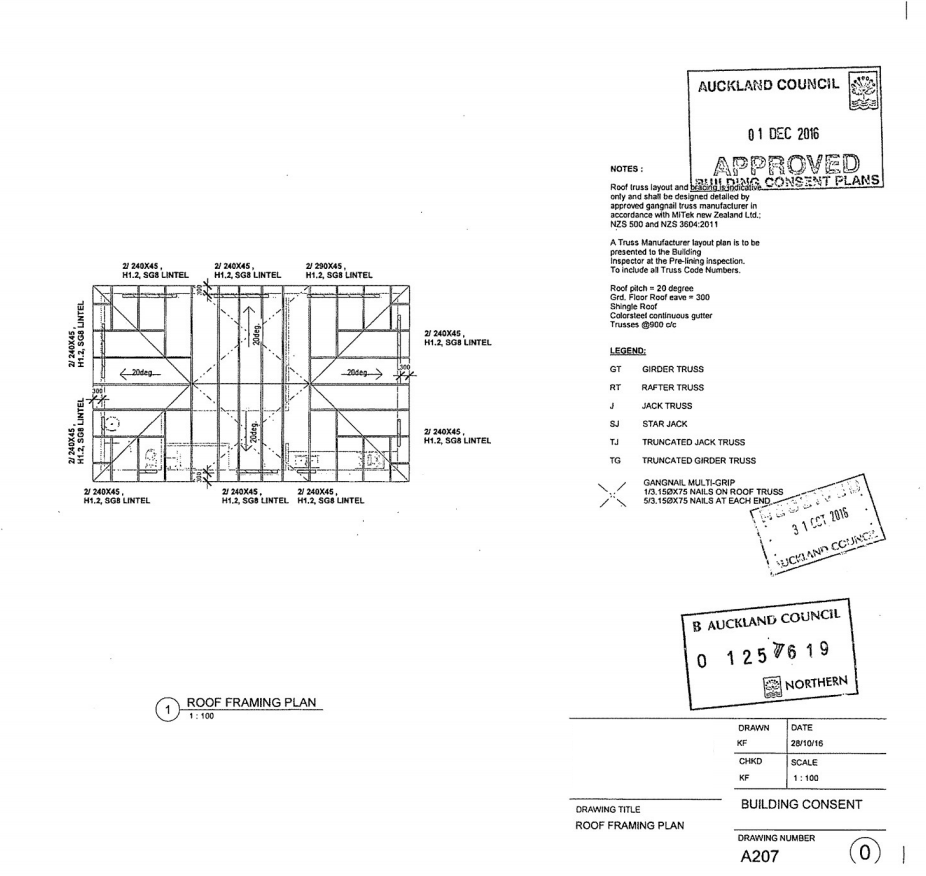

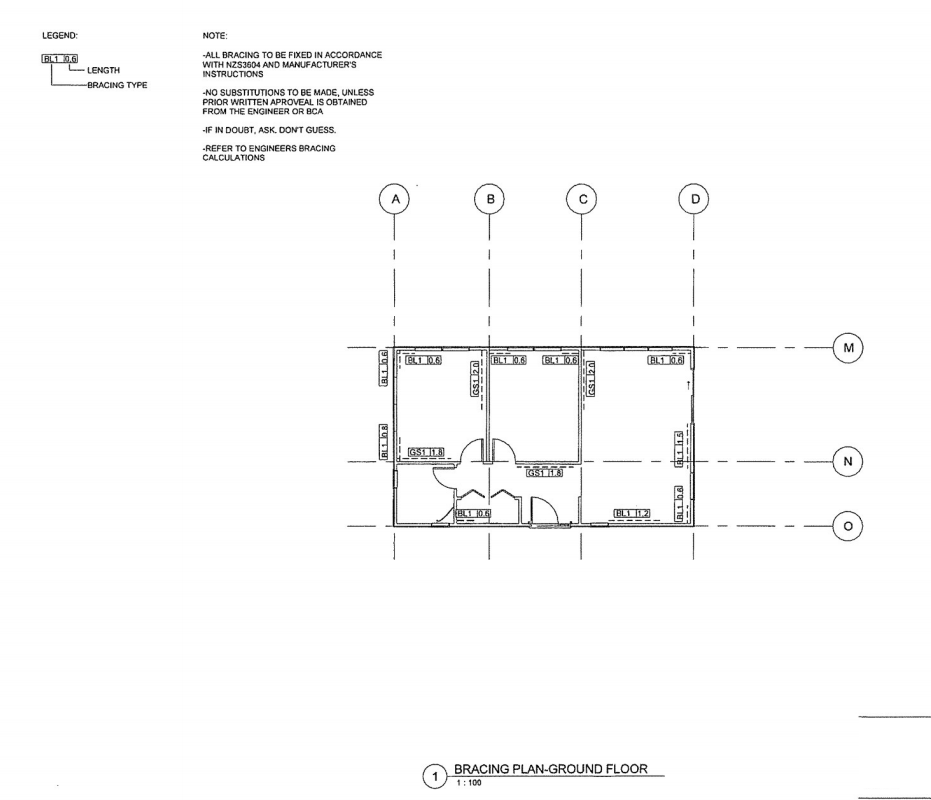

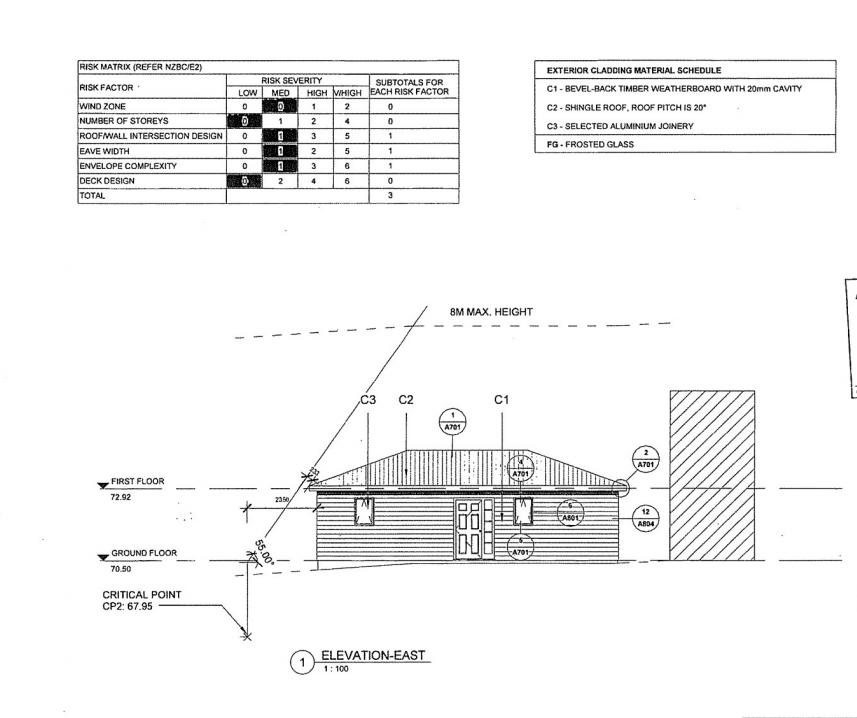

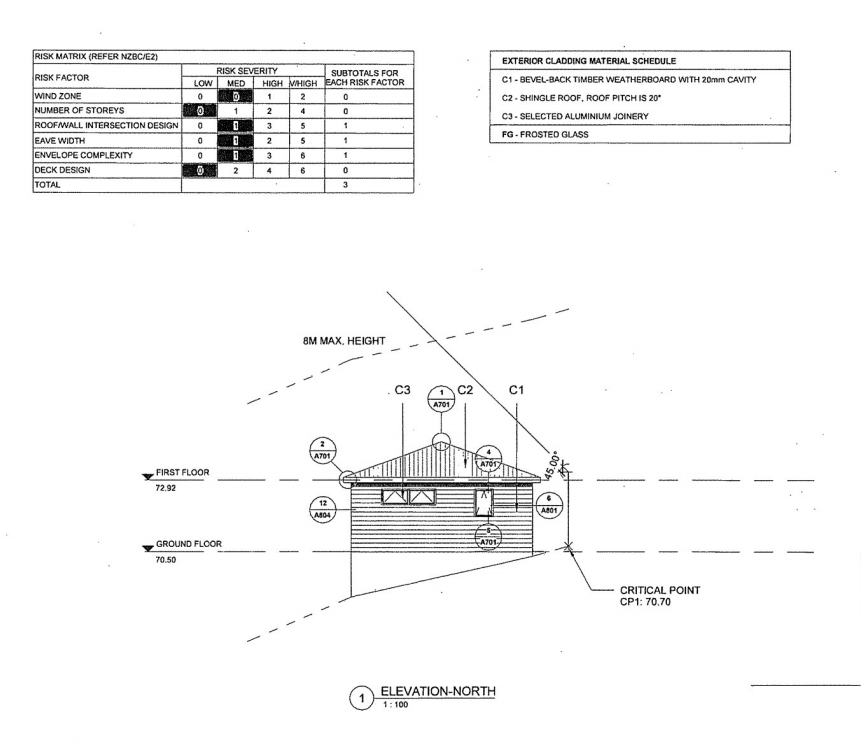

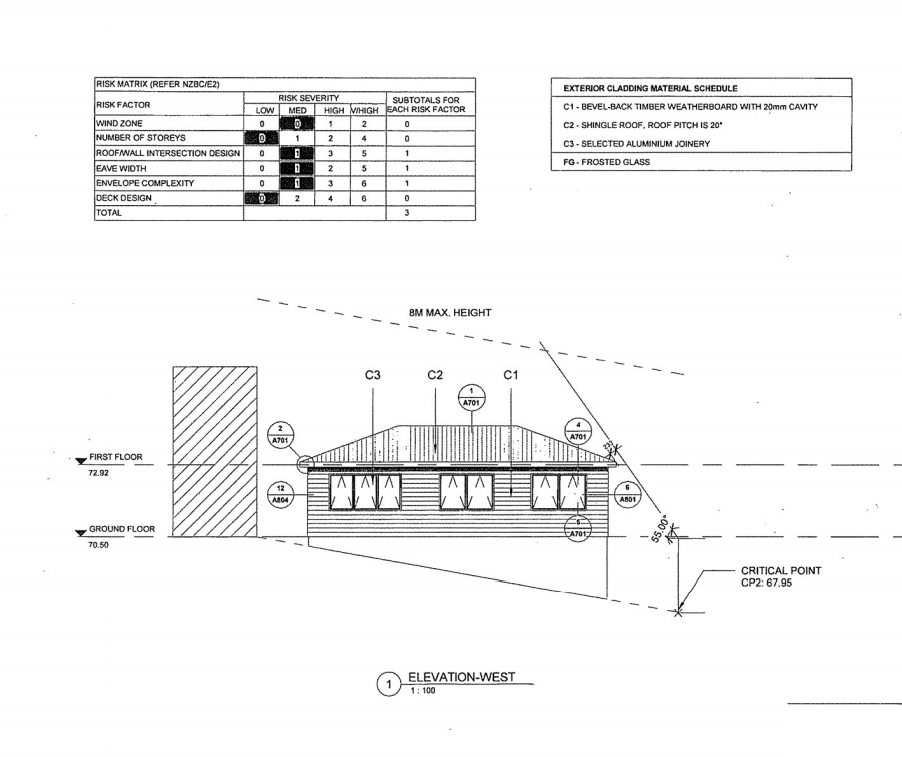

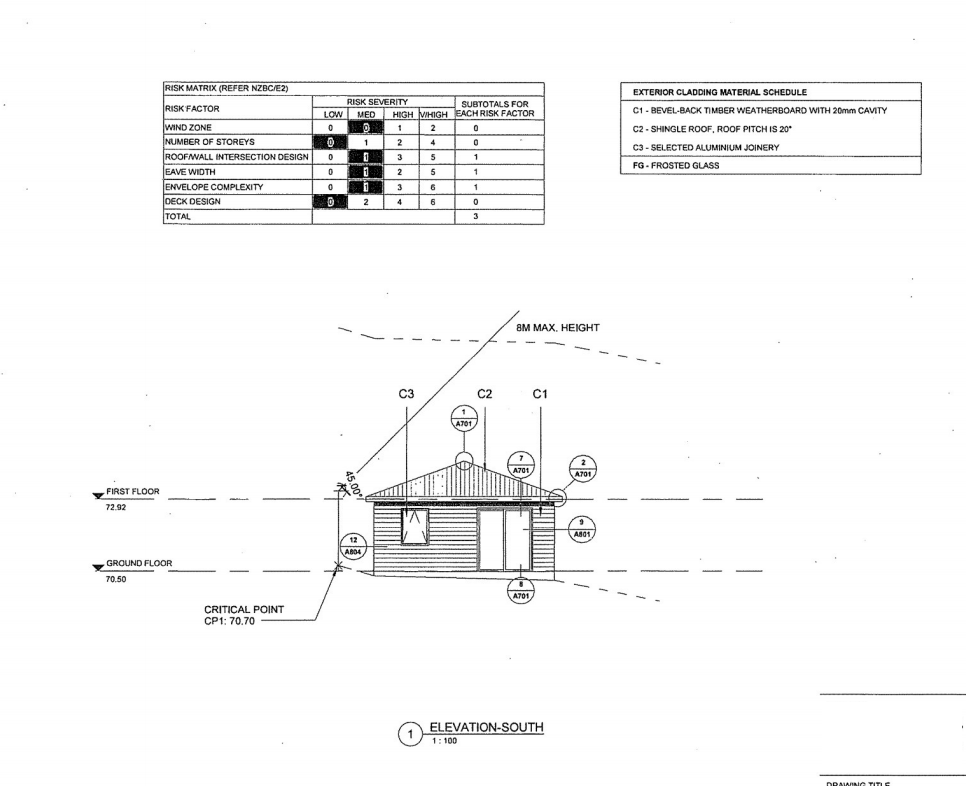

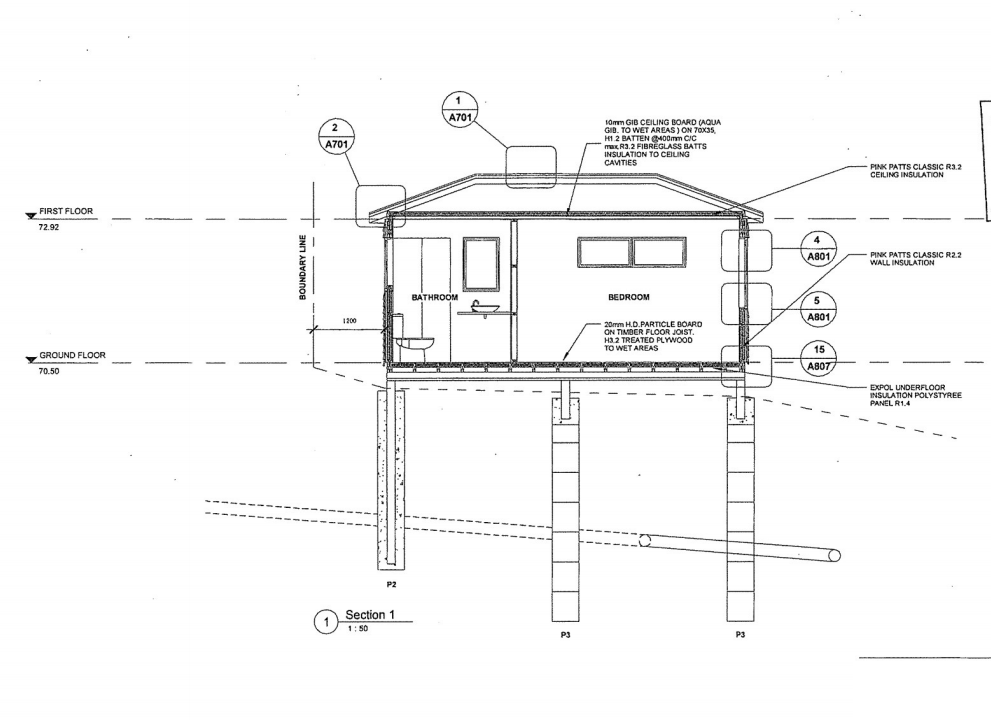

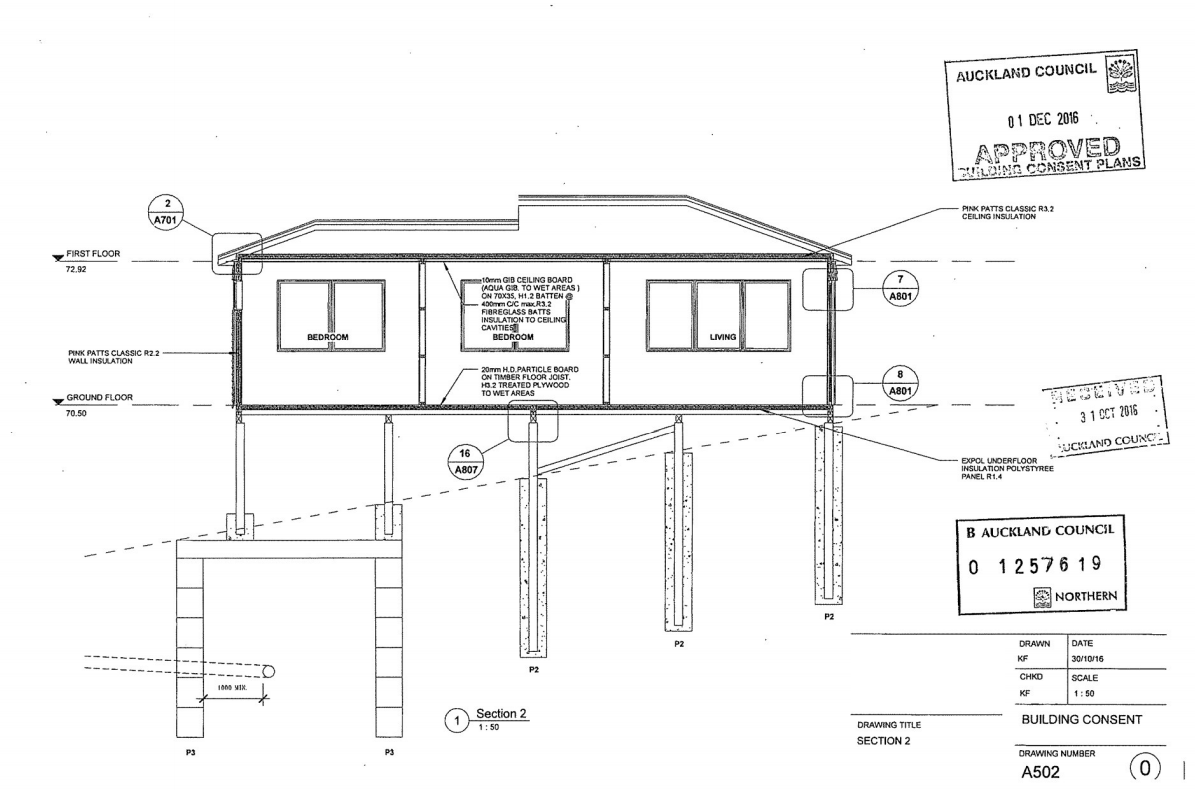

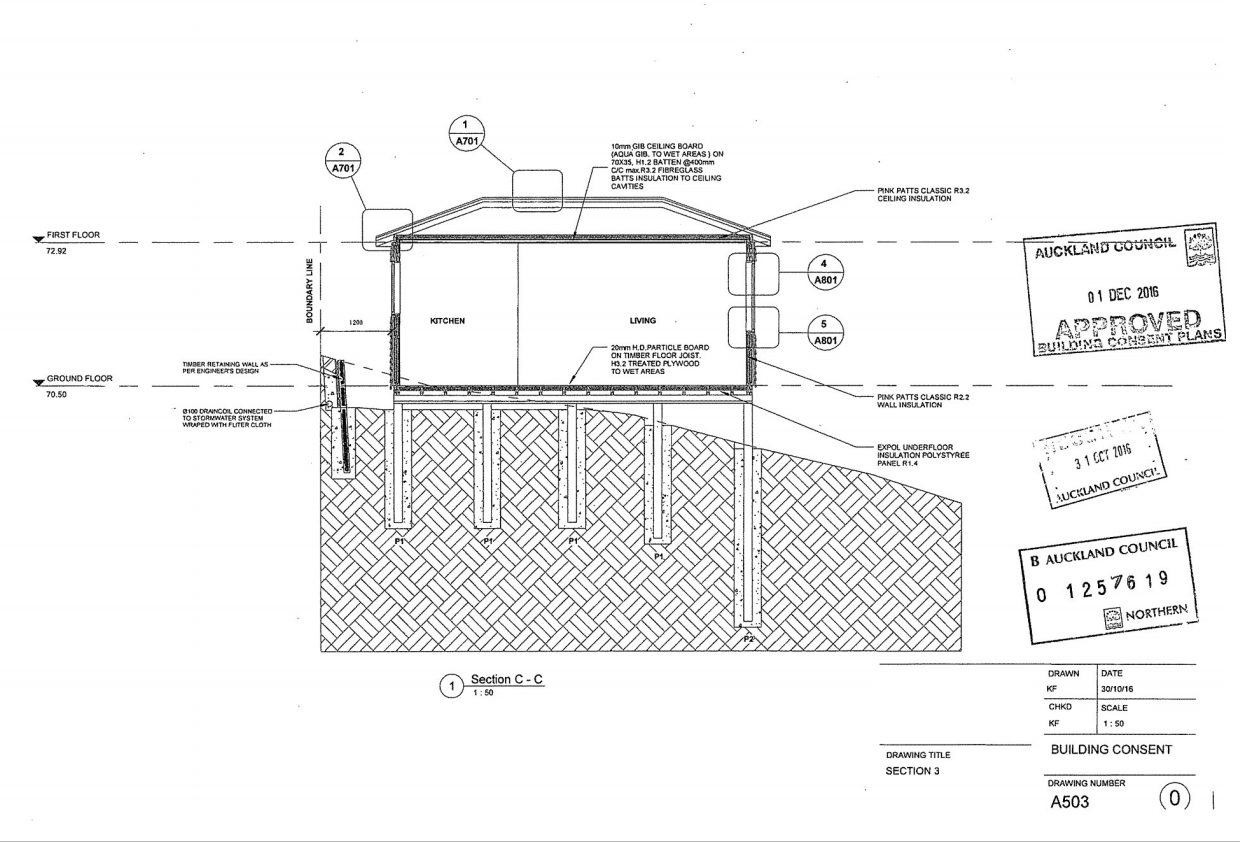

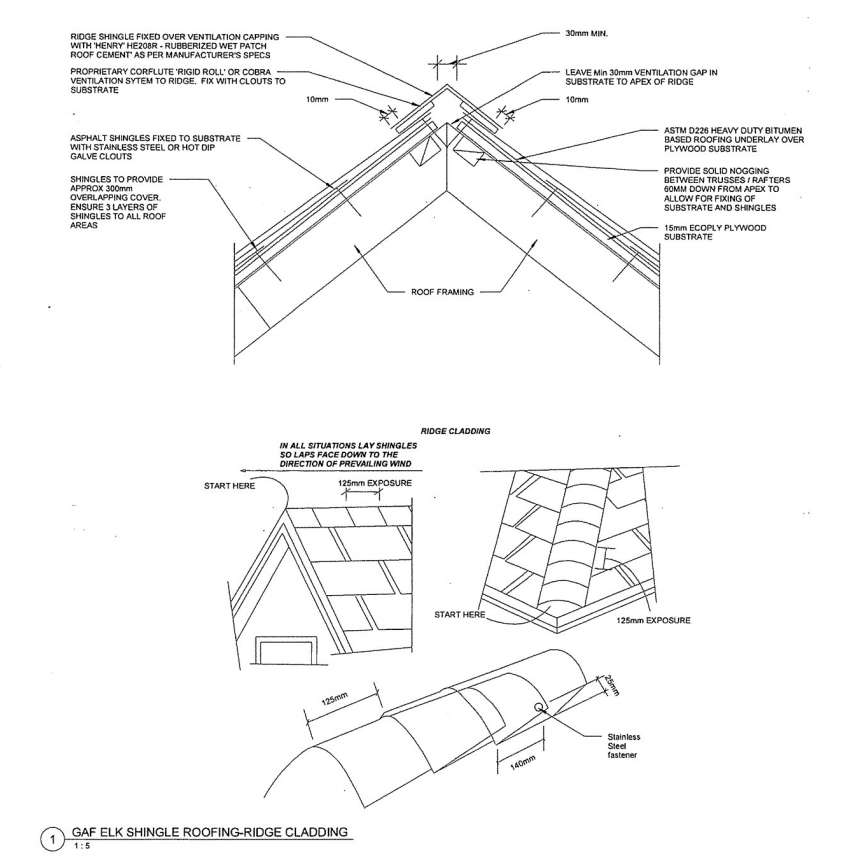

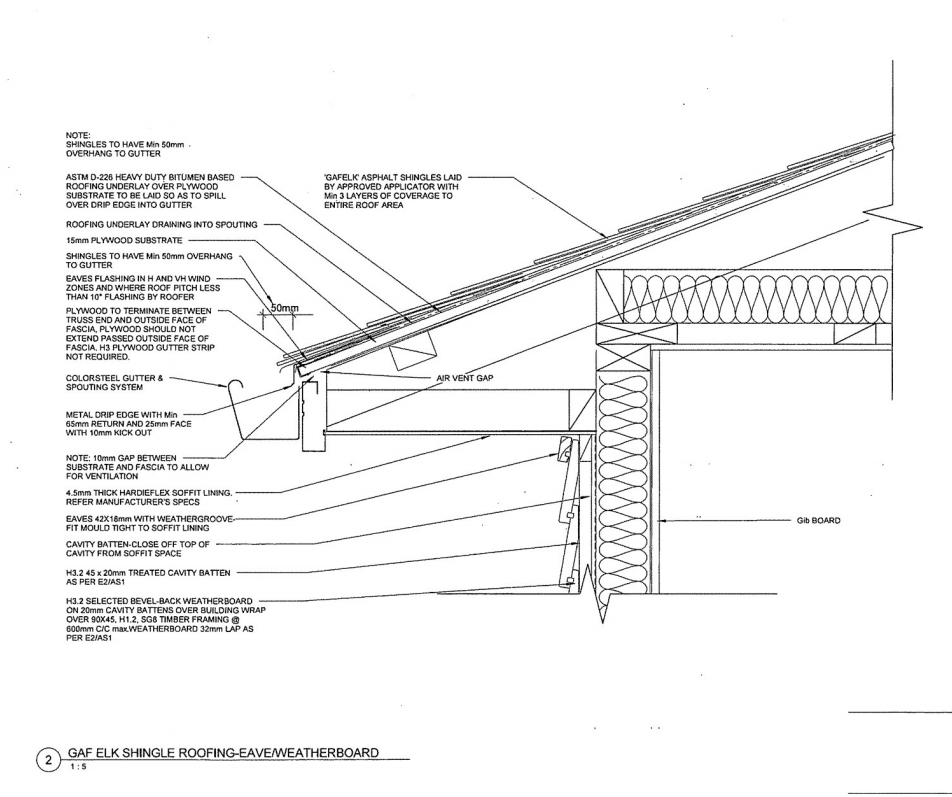

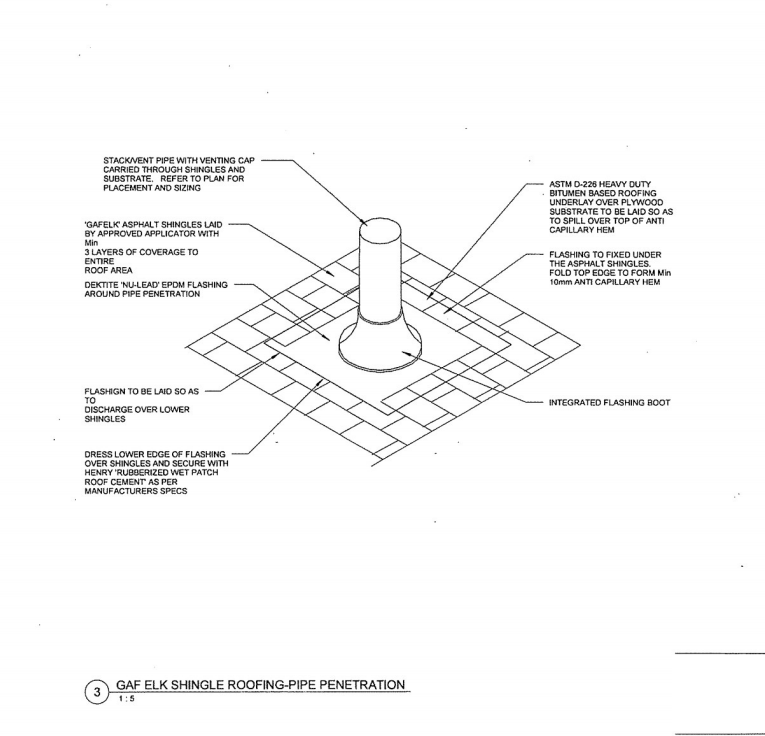

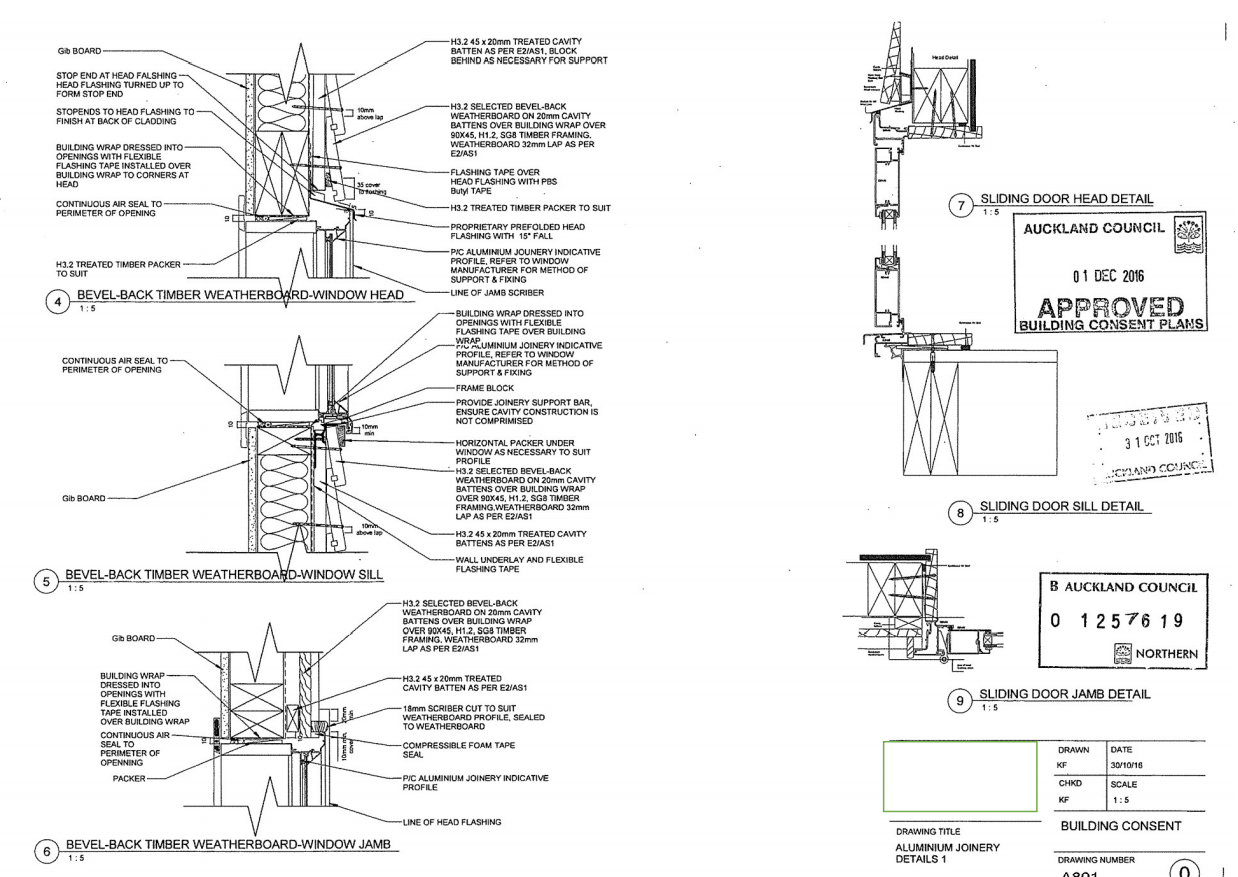

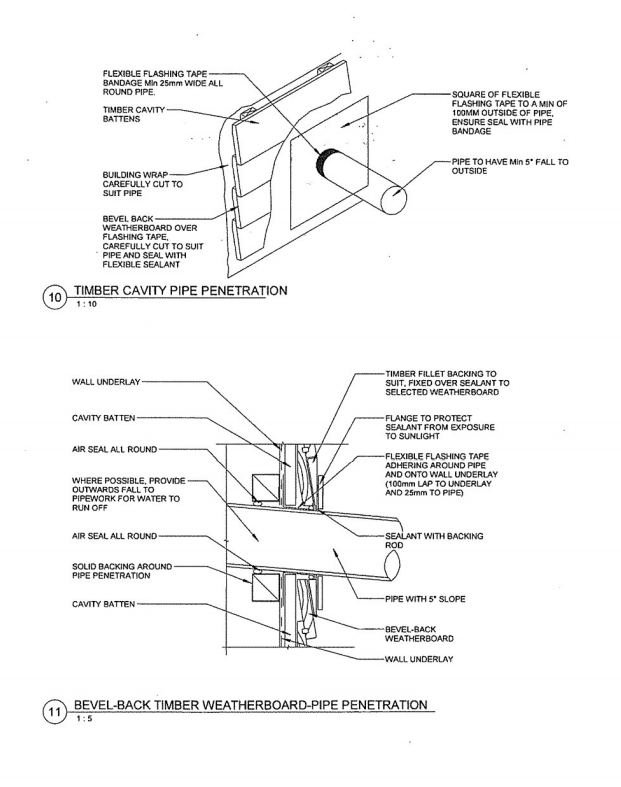

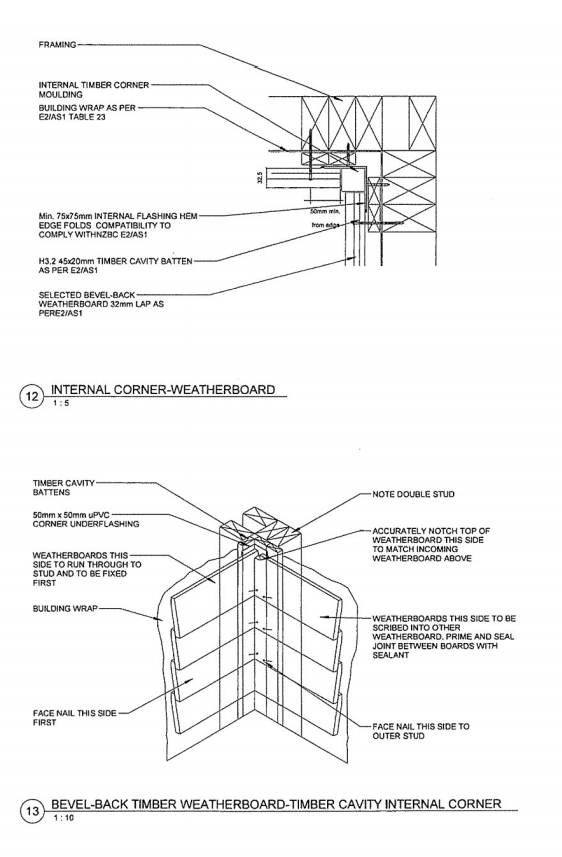

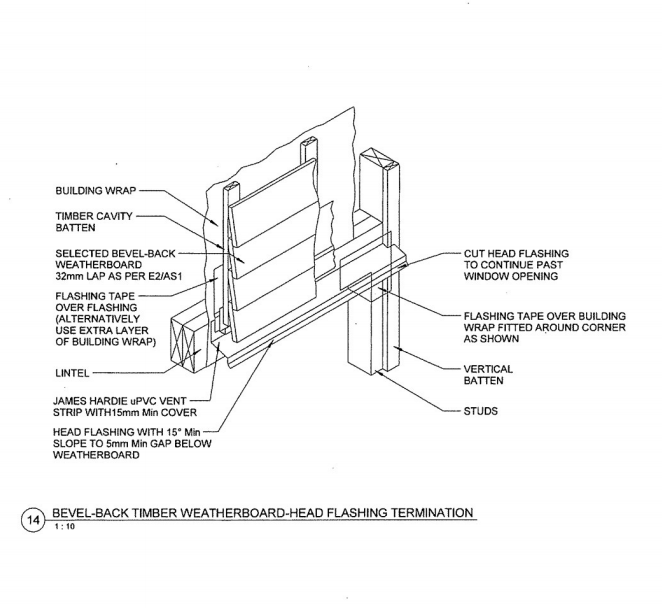

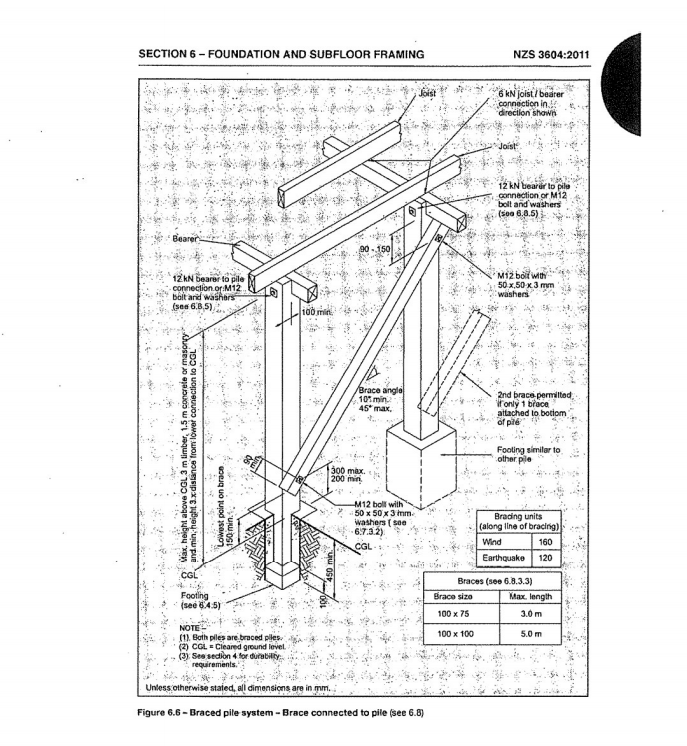

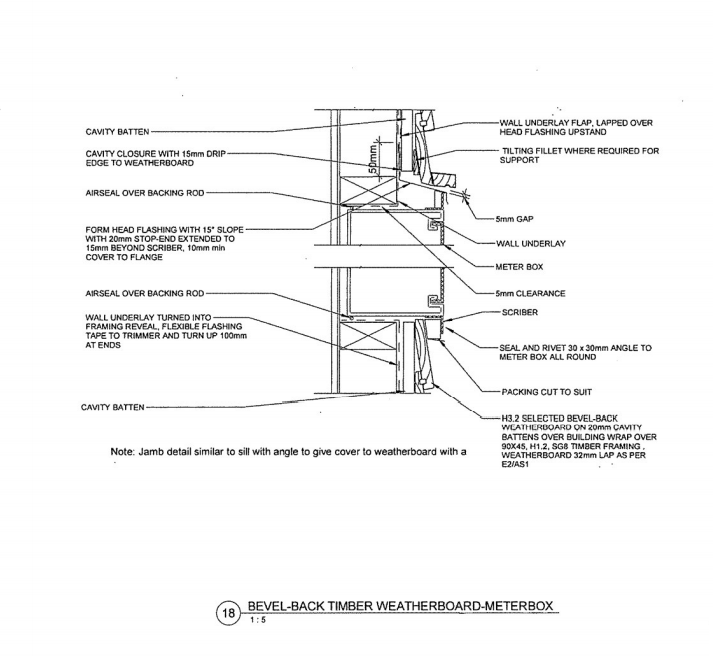

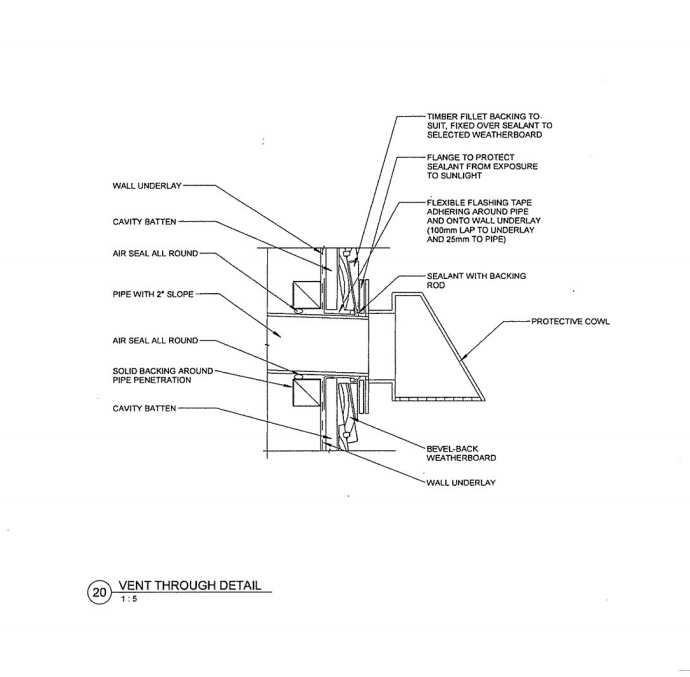

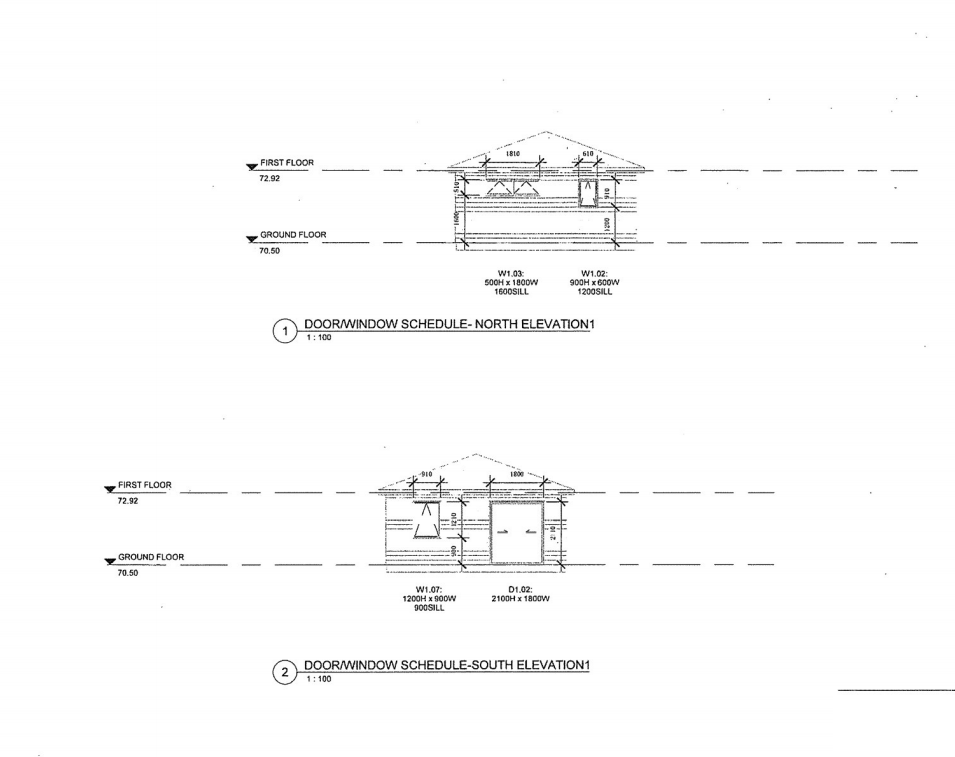

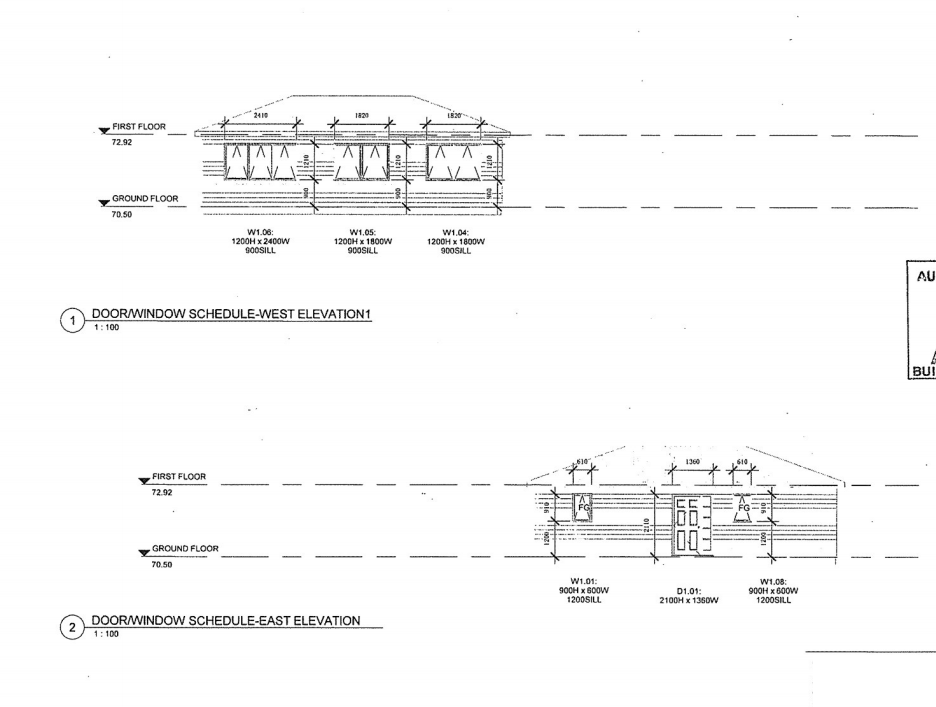

PROJECT : MINOR DWELLING @ A100 A201 A204 A207 A301 A401 A402 A403 A404 A501 A502 A701 A702 A703 A801 A802 A803 A804 A805 A806 A807 A808 A817 A818 A819 A820 A821 A822 A823 SITE PLAN GROUND FLOOR PLAN FOUNDATION PLAN ROOF FRAMING PLAN BRACING PLAN ELEVATION-SOUTH ELEVATION-WEST ELEVATION-NORTH ELEVATION-EAST SECTION 1 SECTION 2 SHINGLE ROOF DETAILS 1 SHINGLE ROOF DETAILS 2 SHINGLE ROOF DETAILS 3 ALUMINIUM JOINERY DETAILS WALL CLADDING DETAILS INTERNAL CORNERS EXTERNAL CORNERS VERTIACL JOINTS DWELLING & DECK JUNCTION DETAIL PROPOSED FOUNDATION DETAILS BRACED PILE DETAIL WET AREA DETAILS 1 WET AREA DETAILS 2 WET AREA DETAILS 3 CEILING PLANE BRACE LUMBERLOK-STUD & TOP PLATE CONNECTION BOTTOM PLATE FIXING FOR BRACING LUMBERLOK-LINTEL FIXING SCHEDULE PLUMBING AND DRAINAGE NOTES: -ALL PLUMBING AND DRAINAGE WORKS TO BE CARRIED OUT IN ACCORDANCE WITH NZBC G13/AS1 WHERE APPLICABLE. ALL CONNECTION TO PUBLIC LINES BY REGISTERED PROFESSIONALS. -ALL WATER SUPPLY TO BE ACCORDANCE WITH NZBC -SHOWER WASTES SHALL HAVE EASY CLEAN TRAPS OR FWG TRAPS. ENSURE ADEQUATED WATERPROOFING IS PROVIDED AROUND SHOWER BASE AND INTO OUTLET. PROVIDE STAINLESS STEEL WASTES. ALL WASTE SHALL BE INSULATED FOR SOUND. SHOWER BASE TO HAVE COPPER TRAY WITH WATERPROOFING LAP OVER AND SEALED TO COPPER BASE. -BATH WASTE DISCHARGEING INTO FWG ARE NOT BE DIRECTLY OPPOSITE ANY OTHER WASTE PIPE INTO THAT GULLY SANITARY PLUMBING SPECIFIED TO COMPLY WITH NZBC E1, G12, G13:AS 1 &AS2 AND TO TERRITORIAL AUTHORITY REQUIREMENTS. PROVIDE ALL BACK VENTS AS NECESSARY. -ALL PIPE WORK IS TO BE CONCEALED AS FAR AS PRACTICAL; -PROVIDE MECHANICAL VENTILATION TO ALL BATHROOMS, KITCHEN AREA, LAUNDRY, AND POWER ROOM, OTV PROPOSED MINOR UNIT BATHROOM LDRY 650@1:40 KITCHEN Dish Set Washer Sink 1001:50 W.C. 01:40 Vnty WIM Tub 40091.60 Shower 1000 GROUND FLOOR ANN 200 658 150 GT1000 100001:100 EXISTING SIS CONN PLUMBING SCHEMATICS 1 : 100 NOTE: GLAZING WITHIN 2000mm OF THE FLOOR LEVELS SHALL COMPLY WITH NZS 4223:PART3. ALL TOUGHENED GALSS TO BE A GRADE SAFETY GLZING. 1 A501 LOGO NOTES 2 1, H1 ENENGY EFFICIENCY Min. R32 FIBERGLASS PINK PATTS INSULATION TO ROOF TRUSSAREA, - Min 2.2 FIBERGLASS PINK PATTS WSULATION TO EXTERNAL WALL - Min, 12 2 FADERGLASS PINK PATTS INSULATION TO WALL BETWEEN GARAGE BLIVING SPACES, -MinRLS TO CONCRETE FLOOR -Min. R3.2 TO SUSPENO FLOOR ABOVE GARAGE MinR0.26 TO GLAZING (DOUBLE GLAZED 2. DOUBLE GLAZNG TO ALL EXTERIOR WINDOWS & DOORS TOTAL 3000 3000 3640 BEDROOM BEDROOM LIVING 10600 NOTES EXTERNAL WALL: SELECTED BEVEL-BACK WEATHERBOARD CLADONG WITH 20mm CAVITY OVER BREATHE TYPE BULONG PAPER WITH WEEP HOLES LBOTTOM CAVITY 1200 CIC ON SGO, H1.2. SmX45mn TMBER FRAMING SC STUDS AT 400nm CIC FOR GROUND LEVEL, 600 CIC FOR GO FIRST LEVEL GENERALLY. SGS STUDS AT 400 CIC FOR WALLS >2.7m M32 TEATMENT FOR ALL EXTERNAL WALLS W1.04 1200H X 1800W 900SILL 6 W1.05 1200H x 1800w A801 900SILL 12 A804) W1.05. 1200H x 2400W 900SILL ENTRY A502 BEDROOM BEDROOM LIVING D1,02: 2100H x 1800W W1.03: SOOH x 1800W 1600SILL! Lone DO A801/ W1.02: 900 x 600W KITCHEN FFL: 70.50 INTERNAL WALL: GB BOARD LINNO BOTH SOES XSAM SGS FRAMING SGO STUOS AT GOM CIC GENERALLY SCA STUDS AT 400 CIC FOR WALL UP TO 2.7m SGB STUDS AT 300mm CIC FOR WALL UP TO 30m DOUBLE SG & STUDS AT 400 CIC FOR WALLS 3.5m W1.07: 1200H x 900W 900SILL RANGEHOOD DO all IL CORY 6 O 01.01: : W1.08 2100H x 1360W SOOH X 600W 1200SILL NOTES ALL TIMBER TO BE SGamin 2. ALL WET AREAS TO BET.CO.TLES SHALL BE INSTALLED WITH DESET and OUR IK WETAREA MEMBRANES OR EQUIVALENT STRICTLY REFER TO MANUFACTURERS SPECS ANO N ACCORDANCE WITH AS3740 ANO TO BRANZ GOOD THING PRACTICE, ZO WATERPROOFINO INTERIOR WET AREAS AREAS PRONE TO WATER SPLASH SHALL COMPLY WITH:30, 21 ANO 3.2 OF NZACES Wy01: 90GM X 600W 1200SILL 1910/0 RINNAI VT24 GAS INFINITY 2000 1910 3500 BATHROOM LDRY KITCHEN OM KEY SMOKE ALARM INSTALLED ON OR NEAR THE CERNG N ACCORDANCE WITH AS1670:6 ANO MANUFACTURERS INSTRUCTIONS SAFETY GLAZING TYPE A MIN, 5MM TOTAL EXTRACTWG FAN WIT Min. EXTRACTION CAPACITY OF 2 Liters per SECOND, APPLY T:240 THROUOHJOIST BRACKETS TO ALLOW AIR DUCT THROUGH MD FLOOR AND OTHER ENCLOSED AREAS MAXIMUM HOLE CUTIS 100 da GAS BOTTLE 45kg. 375 Dia X 1250H FIXED TO EXTERIOR WALL BY WALL BRACKET FLOOR FLOOR PLAN-GROUND FLOOR -1 : 100 TLE FLOORING - TBC BY CLIENT Ground Floor Area: 60ml TUBER TREATMENT SCHEDULE UNLESS SPECFICALLY STATED ELSEWHERE THE FOLLOWING MNIUM LEVELS OF TIMBER TREATMENT SHALL BE USED IN ACCORDANCE WITH NZS3540.2003 & NZ83602 2003 M1.2 INTERIOR WALL FRAMING, MIOFLOOR FRAMING, ROOF AND CEILING FRAMING EXCEPT SKLLION ROOFSI SUBFLOOR FRAMING, EXTERIOR WALL FRAMING, MOFLOOR BOUNDARY JOISTS, SKILLION OR FLAT ROOF FRAMING, ENCLOSED EAVES FRAMING PARAPET FRAMNG HL2 WALL FRAMING & FLOORING TO WET AREAS, BALUSTRADE FRAMING ENCLOSED BALCONY PLY AND FRAMING, INTERNAL GUTTER SUPPORTS, ENCLOSED LINTELS & POSTS SUPPORTING AN ENCLOSED BALCONY, CAVITY BATTENS, PAINTED POSTS AND BEAMS, SKILLION RAFTERS UNDER 10 DEGREE PITCH HAFENCE POSTS. LANDSCAPING TIMBER ETC. MS PILES, POSTS EMBEDDED IN GROUND NERAKOAKS, PERGOLAS ETC) ALL TIMBER MEMBERS TO BE SEPARATED FROM CONCRETE WM PROPER DAMP PROOF COURSE ALL TIMER GASEPLATES AND MEMBERS SUPPORTING FLASHING OR DRAWING TITLE GROUND FLOOR AUCKLAND COUNCIL res 01 DEC 2016 APPROVED Ps: 12 SO HET BESOIENT PLANS IR NE INCASED INTO 0450 X 2000 CONCRETE PILE INTO NUTURAL SOLID GROUND, 100MM BOTTOM COVER. Q P2: 200 SED H5 TIMBER POST INCASED INTO 450 X 3000 CONCRETE PILE INTO NUTURAL SOLID GROUND. 100MM BOTTOM COVER 1000 1 1 2473 22473 2473 2473 P3: $450 X 3000 CONCRETE PILE INTO NUTURAL SOLID GROUND, 100MM BOTTOM COVER P4: 125 X 125 HS POST ON TOP OF CONCRETE BEAM P3 P3 P2 P2 P2 A 240 X 45 BEARERI BOUNDARY XOIST 3/100 X 45 B AUCKLAND COUNCIL P3 P1 d H3.2 TREATED PLYWOOD ABOVE TIMBER FLOOR JOIST IN WET AREA B braio X S BEARERT 0 1 2 576 19 g BOUNDARY JOIST P1 S NORTHERN 2100 XY g P1 g 1240 X 45 BEARER GS P2 P1 a P1 LO P1 P ONLY 13878 TIMBER RETAINING AS PER ENGINEER'S TIMBER FLOOR JOIS 190 X 45400 CRS imy 02 NY 201 1 UCKLAND COUNC FOUNDATION PLAN DRAWN KF 1:100 DATE 02/11/16 SCALE 1: 100 CHKD KF BUILDING CONSENT DRAWING TITLE FOUNDATION PLAN DRAWING NUMBER A204 0:1 AUCKLAND COUNCIL 01 DEC 2016 NOTES: APPROVED Roof truss layout and bracing.sindicative LaDING CONSENT PLANS only and shall be designed detailed by approved gangnail truss manufacturer in accordance with MITek new Zealand Ltd.: NZS 500 and NZS 3604:2011 A Truss Manufacturer layout plan is to be presented to the Building Inspector at the Pre-lining inspection To include all Truss Code Numbers. Roof pitch = 20 degree Grd Floor Roof eave - 300 Shingle Roof Calorsteel continuous gutter Trusses 900 cc 2 240X45. H1.2, SGS LINTEL 21 240X45, H1.2. SG8 LINTEL 21 290X45. H1.2, SG8 LINTEL 21 240X45, H1.2, SGS UNTEL Caer 2/ 240X45 11.2. SGB LINTEL 20deg 20deg LEGEND GT GIRDER TRUSS RT RAFTER TRUSS J JACK TRUSS SU STAR JACK 2/ 240X45. H1.2, SGB LINTEL 24 240X45. H1.2, SGS LINTEL TJ TRUNCATED JACK TRUSS TG TRUNCATED GIRDER TRUSS 2 240X45, H1.2, SGB LINTEL 21 240X4S. 2/ 240X45 H1.2, SGB LINTEL H1.2, SGS LINTEL GANGNAIL MULTI-GRIP 1/3.15@x75 NAILS ON ROOF TRUSS 5/3.150x75 NAILS AT EACH END 31 CCT 2015 UCHANN CCC B AUCKLAND COUNCIL 0 1 2 576 19 NORTHERN ROOF FRAMING PLAN 1: 100 DRAWN KF DATE 28/10/16 CHKD KF SCALE 1:100 BUILDING CONSENT DRAWING TITLE ROOF FRAMING PLAN DRAWING NUMBER A207 1 LEGEND NOTE: R 1.00 LENGTH -BRACING TYPE -ALL BRACING TO BE FIXED IN ACCORDANCE WITH NZS3604 AND MANUFACTURER'S INSTRUCTIONS -NO SUBSTITUTIONS TO BE MADE, UNLESS PRIOR WRITTEN APROVEAL IS OBTAINED FROM THE ENGINEER OR BCA IF IN DOUBT, ASK. DONT GUESS. -REFER TO ENGINEERS BRACING CALCULATIONS A - M ELLO BL106 BILL (BL1270 BL16.6 [U | ] OZ 159 GS1120 BLLO. GSI BL115 - 1 N CALL 0.0 ELLI (BL11121 BRACING PLAN-GROUND FLOOR RISK MATRIX (REFER NZBC/E2) RISK FACTOR IN EXTERIOR CLADDING MATERIAL SCHEDULE C1 - BEVEL-BACK TIMBER WEATHERBOARD WITH 20mm CAVITY C2 - SHINGLE ROOF, ROOF PITCH IS 20" C3 - SELECTED ALUMINIUM JOINERY FG - FROSTED GLASS RISK SEVERITY SUBTOTALS FOR LOW MED HIGH MHIGH EACH RISK FACTOR 0 0 1 0 0 1 2 4 0 0 1 3 5 1 0 1 2 5 1 0 . 3 6 1 WIND ZONE NUMBER OF STOREYS ROOF WALL INTERSECTION DESIGN EAVE WIDTH ENVELOPE COMPLEXITY DECK DESIGN TOTAL 2 4 6 0 3 BM MAX. HEIGHT 1 C3 C2 C1 A701 A701 A701 FIRST FLOOR 72.92 2350 12 ARD4 000 GROUND FLOOR 70.50 ser 55.00 CRITICAL POINT CP2: 67.95 ELEVATION-EAST 1 : 100 RISK MATRIX (REFER NZBC/E2) RISK FACTOR WIND ZONE NUMBER OF STOREYS ROOFWALL INTERSECTION DESIGN EAVE WIDTH ENVELOPE COMPLEXITY DECK DESIGN TOTAL RISK SEVERITY SUBTOTALS FOR LOW MED HIGH MHIGH EACH RISK FACTOR 0 1 2 0 0 1 2 4 0 0 1 3 5 1 0 1 2 5 1 0 1 3 6 1 0 2 4 6 0 3 PDP-om EXTERIOR CLADDING MATERIAL SCHEDULE C1-BEVEL-BACK TIMBER WEATHERBOARD WITH 20mm CAVITY C2 - SHINGLE ROOF, ROOF PITCH IS 20* C3 - SELECTED ALUMINIUM JOINERY FG - FROSTED GLASS 1 8M MAX. HEIGHT C3 C2 C1 A701 A701 FIRST FLOOR 72.92 12 A804 A801 A701 GROUND FLOOR 70.50 CRITICAL POINT CP1: 70.70 ELEVATION-NORTH 1:100 RISK MATRIX (REFER NZBC/E2) RISK FACTOR WIND ZONE NUMBER OF STOREYS ROOFWALL INTERSECTION DESIGN EAVE WIDTH ENVELOPE COMPLEXITY DECK DESIGN TOTAL RISK SEVERITY SUBTOTALS FOR LOW MED HIGH MIHIGH EACH RISK FACTOR 0 D 1 2 0 0 1 2 4 0 0 1 3 5 1 0 2 5 1 EXTERIOR CLADDING MATERIAL SCHEDULE C1-BEVEL-BACK TIMBER WEATHERBOARD WITH 20mm CAVITY C2 - SHINGLE ROOF, ROOF PITCH IS 20" C3 - SELECTED ALUMINIUM JOINERY FG-FROSTED GLASS 0 3 6 1 2 4 6 0 3 BM MAX. HEIGHT 1 C3 C2 C1 A701 A701 A701 FIRST FLOOR 72.92 12 A804 NET A801 GROUND FLOOR 70.50 CAT014 CRITICAL POINT CP2: 67.95 1 ELEVATION- WEST 1:100 RISK MATRIX (REFER NZBC/E2) EXTERIOR CLADDING MATERIAL SCHEDULE RISK FACTOR WIND ZONE RISK SEVERITY SUBTOTALS FOR LOW MED HIGH MHIGH EACH RISK FACTOR 0 1 2 0 0 1 2 4 0 0 1 3 5 1 0 1 2 2 5 1 0 1 3 3 6 1 0 2 4 6 O 3 C1 - BEVEL-BACK TIMBER WEATHERBOARD WITH 20mm CAVITY C2 - SHINGLE ROOF, ROOF PITCH IS 200 C3 - SELECTED ALUMINIUM JOINERY FG - FROSTED GLASS NUMBER OF STOREYS ROOFWALL INTERSECTION DESIGN EAVE WIDTH ENVELOPE COMPLEXITY DECK DESIGN TOTAL 8M MAX. HEIGHT C3 C2 C1 A101 A701 A701 FIRST FLOOR 72.92 ABD4 GROUND FLOOR 70.50 A701 CRITICAL POINT CP1: 70.70 ELEVATION-SOUTH 1: 100 ODMANNO TITLE A701 A701 10mm GID CEILING BOARD (AQUA GID. TO WET AREAS) ON 70X35. M1 2 BATTEN A400M CIC max R3.2 FIBREGLASS BATTS INSULATION TO CEILING CAVITIES PINK PATTS CLASSIC R32 CEILING INSULATION FIRST FLOOR 72.92 - A801/ PINK PATTS CLASSIC R22 WALL INSULATION BATHROOM BEDROOM 5 AB01 1200 20mm H.D.PARTICLE BOARD ON TIMBER FLOOR JOIST. H3.2 TREATED PLYWOOD TO WET AREAS GROUND FLOOR 70.50 15 A807 EXPOL UNDERFLOOR INSULATION POLYSTYREE PANEL R1.4 Section 1 1:50 P3 P3 AUCKLAND COUNCIL SA ES 01 DEC 2016 APPROVED LOIN CONSENT PLANS 2 A701 PINK PATTS CLASSIC R32 CEILING INSULATION FIRST FLOOR 72.92 7 AB01 mm GID CEILING BOARD (AQUA GIB. TO WET AREAS ON 70X35, H1.2 BATTEN 40 CIC max 3.2 FIBREGLASS BATTS INSULATION TO CEILING CAVITIES BEDROOM BEDROOM LIVING PINK PATTS CLASSIC R22 WALL INSULATION 20mm H.O.PARTICLE BOARD ON TIMBER FLOOR JOIST. 10.2 TREATED PLYWOOD TO WET AREAS A801 GROUND FLOOR 70.50 31 CCT 2016 UCKLAND COUNCE 16 A807 EXPOL UNDERFLOOR INSULATION POLYSTYREE PANEL R1.4 th B AUCKLAND COUNCIL 0 1 257 6 19 NORTHERN P2 P2 DRAWN KF P2 DATE 30/10/16 SCALE 1:50 100 VIX CHKD KF Section 2 1:50 BUILDING CONSENT DRAWING TITLE SECTION 2 P3 P3 DRAWING NUMBER A502 01 1 A701 A701 10mm GIB CEILING BOARD (AQUA GIS. TO WET AREAS) ON 70x35, HI.2 BATTEN 400mm C/C max R3.2 FIBREGLASS BATTS INSULATION TO CEILING CAVITIES PINK PATTS CLASSIC R3.2 CEILING INSULATION FIRST FLOOR 72.92 LAS AUCKLAND COUNCIL +981 A801 BOUNDARY 1290 KITCHEN LIVING 5 A801 01 DEC 2016 APPROVED BUILDING CONSENT PLANS TINDER RETAINING WALL AS PER ENGINEERS DESIGN 20m H.D.PARTICLE BOARD ON TIMBER FLOOR JOIST. H3.2 TREATED FLYWOOD TO WET AREAS GROUND FLOOR 70.50 PINK PATTS CLASSIC R22 WALL INSULATION 2100 DRANCOIL CONNECTED TO STORMWATER SYSTEM WIUPED WITH FUTER CLOTH EXPOL UNDERFLOOR INSULATION POLYSTYREE PANEL R1.4 31 CCT 2015 AUCKLAND COUNCI: B AUCKLAND COUNCIL 0 1 2576 19 NORTHERN Section C-C 1:50 DRAWN KF DATE 30/10/16 CHKD SCALE 1:50 KF BUILDING CONSENT DRAWING TITLE SECTION 3 DRAWING NUMBER A503 1 30mm MIN. RIDGE SHINGLE FIXED OVER VENTILATION CAPPING WITH HENRY HE208R - RUBBERIZED WET PATCH ROOF CEMENT AS PER MANUFACTURER'S SPECS PROPRIETARY CORFLUTE 'RIGID ROLL' OR COBRA VENTILATION SYTEM TO RIDGE, FIX WITH CLOUTS TO SUBSTRATE LEAVE Min 30mm VENTILATION GAP IN SUBSTRATE TO APEX OF RIDGE 10mm 10mm ASPHALT SHINGLES FIXED TO SUBSTRATE WITH STAINLESS STEEL OR HOT DIP GALVE CLOUTS ASTM D226 HEAVY DUTY BITUMEN BASED ROOFING UNDERLAY OVER PLYWOOD SUBSTRATE SHINGLES TO PROVIDE APPROX 300mm OVERLAPPING COVER ENSURE 3 LAYERS OF SHINGLES TO ALL ROOF AREAS PROVIDE SOLID NOGGING BETWEEN TRUSSES I RAFTERS GOMM DOWN FROM APEX TO ALLOW FOR FIXING OF SUBSTRATE AND SHINGLES 15mm ECOPLY PLYWOOD SUBSTRATE ROOF FRAMING RIDGE CLADDING IN ALL SITUATIONS LAY SHINGLES SO LAPS FACE DOWN TO THE DIRECTION OF PREVAILING WIND START HERE 125mm EXPOSURE START HERE 125mm EXPOSURE 125mm Stainless Steel fastener 140mm GAF ELK SHINGLE ROOFING-RIDGE CLADDING 1:5 NOTE: SHINGLES TO HAVE Min 50mm. OVERHANG TO GUTTER ASTM D-226 HEAVY DUTY BITUMEN BASED ROOFING UNDERLAY OVER PLYWOOD SUBSTRATE TO BE LAID SO AS TO SPILL OVER DRIP EDGE INTO GUTTER "GAFELK ASPHALT SHINGLES LAID BY APPROVED APPLICATOR WITH Min 3 LAYERS OF COVERAGE TO ENTIRE ROOF AREA ROOFING UNOERLAY DRAINING INTO SPOUTING 15mm PLYWOOD SUBSTRATE SHINGLES TO HAVE Min 50mm OVERHANG TO GUTTER EAVES FLASHING IN H AND VH WIND ZONES AND WHERE ROOF PITCH LESS THAN 10" FLASHING BY ROOFER PLYWOOD TO TERMINATE BETWEEN TRUSS END AND OUTSIDE FACE OF FASCIA, PLYWOOD SHOULD NOT EXTEND PASSED OUTSIDE FACE OF FASCIA, H3 PLYWOOD GUTTER STRIP NOT REQUIRED 50mg AIR VENT GAP COLORSTEEL GUTTER & SPOUTING SYSTEM METAL DRIP EDGE WITH Min 65mm RETURN AND 25mm FACE WITH 10mm KICK OUT Gib BOARD NOTE: 10mm GAP BETWEEN SUBSTRATE AND FASCIA TO ALLOW FOR VENTILATION 4.5mm THICK HARDIEFLEX SOFFIT LINING. REFER MANUFACTURER'S SPECS EAVES 42X18mm WITH WEATHERGROOVE FIT MOULD TIGHT TO SOFFIT LINING CAVITY BATTEN-CLOSE OFF TOP OF CAVITY FROM SOFFIT SPACE H3.2 45 x 20mm TREATED CAVITY BATTEN AS PER E2/AS1 HJ.2 SELECTED BEVEL-BACK WEATHERBOARD ON 20mm CAVITY BATTENS OVER BUILDING WRAP OVER 90X45. H1.2, SGG TIMBER FRAMING 600mm C/C max WEATHERBOARD 32mm LAPAS PER E2AS1 GAF ELK SHINGLE ROOFING-EAVEWEATHERBOARD 2 1:5 STACKIVENT PIPE WITH VENTING CAP CARRIED THROUGH SHINGLES AND SUBSTRATE. REFER TO PLAN FOR PLACEMENT AND SIZING ASTM D-226 HEAVY DUTY BITUMEN BASED ROOFING UNDERLAY OVER PLYWOOD SUBSTRATE TO BE LAID SO AS TO SPILL OVER TOP OF ANTI CAPILLARY HEM 'GAFELK ASPHALT SHINGLES LAID BY APPROVED APPLICATOR WITH Min 3 LAYERS OF COVERAGE TO ENTIRE ROOF AREA DEKTITE 'NU-LEAD EPDM FLASHING AROUND PIPE PENETRATION FLASHING TO FIXED UNDER THE ASPHALT SHINGLES FOLD TOP EDGE TO FORM Min 10mm ANTI CAPILLARY HEM FLASHIGN TO BE LAID SO AS TO DISCHARGE OVER LOWER SHINGLES INTEGRATED FLASHING BOOT DRESS LOWER EDGE OF FLASHING OVER SHINGLES AND SECURE WITH HENRY'RUBBERIZED WET PATCH ROOF CEMENT AS PER MANUFACTURERS SPECS GAF ELK SHINGLE ROOFING-PIPE PENETRATION 3 1:5 1 Gib BOARD -H3.2 45 x 20mm TREATED CAVITY BATTEN AS PER E2IAS1, BLOCK BEHIND AS NECESSARY FOR SUPPORT ada STOP END AT HEAD FALSHING HEAD FLASHING TURNED UP TO FORM STOP END STOPENDS TO HEAD FLASHING TO FINISH AT BACK OF CLADDING 10 abolag 219 BUILDING WRAP DRESSED INTO- OPENINGS WITH FLEXIBLE FLASHING TAPE INSTALLED OVER BUILDING WRAP TO CORNERS AT HEAD H3.2 SELECTED BEVEL-BACK WEATHERBOARD ON 20mm CAVITY BATTENS OVER BUILDING WRAP OVER 90X45, H1.2. SG8 TIMBER FRAMING. WEATHERBOARD 32mm LAP AS PER EZASI -FLASHING TAPE OVER HEAD FLASHING WITH PBS Buty TAPE -H3.2 TREATED TIMBER PACKER TO SUIT 95 ht CONTINUOUS AIR SEAL TO PERIMETER OF OPENING 119 9th 100 SLIDING DOOR HEAD DETAIL 1:5 AUCKLAND COUNCIL Y H3.2 TREATED TIMBER PACKER TO SUIT PROPRIETARY PREFOLDED HEAD FLASHING WITH 15' FALL -PIC ALUMINIUM JOUNERY INDICATIVE PROFILE, REFER TO WINDOW MANUFACTURER FOR METHOD OF SUPPORT & FIXING LINE OF JAMB SCRIBER 01 DEC 2016 BEVEL-BACK TIMBER WEATHERBOARD-WINDOW HEAD 1:5 APPROVED BUILDING CONSENT PLANS HIP CONTINUOUS AIR SEAL TO PERIMETER OF OPENING BUILDING WRAP DRESSED INTO OPENINGS WITH FLEXIBLE FLASHING TAPE OVER BUILDING -WRALUMINIUM JOINERY INDICATIVE PROFILE, REFER TO WINDOW MANUFACTURER FOR METHOD OF SUPPORT & FIXING FRAME BLOCK -PROVIDE JOINERY SUPPORT BAR, ENSURE CAVITY CONSTRUCTION IS NOT COMPRIMISED mm min W 3 1 OCT 2016 CHAN COUNCE ON Gib BOARD HORIZONTAL PACKER UNDER WINDOW AS NECESSARY TO SUIT PROFILE -H3.2 SELECTED BEVEL-BACK WEATHERBOARD ON 20mm CAVITY BATTENS OVER BUILDING WRAP OVER 90X4S, H1.2, SGS TIMBER FRAMING.WEATHERBOARD 32mm LAP AS PER EPIASI H3.2 45 x 20mm TREATED CAVITY BATTENS AS PER EIAS1 -WALL UNDERLAY AND FLEXIBLE FLASHING TAPE SLIDING DOOR SILL DETAIL 1:5 above lap 5 BEVEL-BACK TIMBER WEATHERBOARD-WINDOW SILL 1:5 B AUCKLAND COUNCIL -H3.2 SELECTED BEVEL-BACK WEATHERBOARD ON 20mm CAVITY BATTENS OVER BUILDING WRAP OVER 90X45, H12 SGS TIMBER FRAMING. WEATHERBOARD 32mm LAP AS PER ELIAS1 0 1 2576 19 Gila BOARD NORTHERN -H3.2 45 x 20mm TREATED CAVITY BATTEN AS PER E2/AS1 9 SLIDING DOOR JAMB DETAIL 1:5 BUILDING WRAP DRESSED INTO OPENINGS WITH FLEXIBLE FLASHING TAPE INSTALLED OVER BUILDING WRAP CONTINUOUS AIR SEAL TO PERIMETER OF OPENNING PACKER 18mm SCRIBER CUT TO SUIT WEATHERBOARD PROFILE, SEALED TO WEATHERBOARD COMPRESSIBLE FOAM TAPE SEAL DRAWN KF -PIC ALUMINIUM JOINERY INDICATIVE PROFILE DATE 30/10/16 SCALE 1:5 CHKD KF LINE OF HEAD FLASHING BUILDING CONSENT BEVEL-BACK TIMBER WEATHERBOARD-WINDOW JAMB 6 DRAWING TITLE ALUMINIUM JOINERY DETAILS 1 1:5 DRAWING NUMBER 001 FLEXIBLE FLASHING TAPE BANDAGE MIN 25mm WIDE ALL ROUND PIPE TIMBER CAVITY BATTENS -SQUARE OF FLEXIBLE FLASHING TAPE TO A MIN OF 100MM OUTSIDE OF PIPE. ENSURE SEAL WITH PIPE BANDAGE -PIPE TO HAVE Min 5' FALL TO OUTSIDE BUILDING WRAP- CAREFULLY CUT TO SUIT PIPE BEVEL BACK WEATHERBOARD OVER FLASHING TAPE CAREFULLY CUT TO SUIT PIPE AND SEAL WITH FLEXIBLE SEALANT 10 TIMBER CAVITY PIPE PENETRATION 1:10 WALL UNDERLAY -TIMBER FILLET BACKING TO SUIT, FIXED OVER SEALANT TO SELECTED WEATHERBOARD CAVITY BATTEN AIR SEAL ALL ROUND -FLANGE TO PROTECT SEALANT FROM EXPOSURE TO SUNLIGHT -FLEXIBLE FLASHING TAPE ADHERING AROUND PIPE AND ONTO WALL UNDERLAY (100mm LAP TO UNDERLAY AND 25mm TO PIPE) WHERE POSSIBLE, PROVIDE OUTWARDS FALL TO PIPEWORK FOR WATER TO RUN OFF AIR SEAL ALL ROUND SEALANT WITH BACKING ROD SOLID BACKING AROUND PIPE PENETRATION CAVITY BATTEN -PIPE WITH 5' SLOPE BEVEL-BACK WEATHERBOARD -WALL UNDERLAY 11 BEVEL-BACK TIMBER WEATHERBOARD-PIPE PENETRATION 1:5 FRAMING INTERNAL TIMBER CORNER MOULDING BUILDING WRAP AS PER EZIAS1 TABLE 23 WM 32.5 Min. 75x75mm INTERNAL FLASHING HEM EDGE FOLDS COMPATIBILITY TO COMPLY WITHNZBC EZ/AS1 Om mi from H3.2 45x20mm TIMBER CAVITY BATTEN AS PER EZ/AS1 SELECTED BEVEL-BACK- WEATHERBOARD 32mm LAP AS PERE/AS1 12 INTERNAL CORNER-WEATHERBOARD 1:5 TIMBER CAVITY BATTENS NOTE DOUBLE STUD 50mm x 50mm PVC CORNER UNDERFLASHING ACCURATELY NOTCH TOP OF WEATHERBOARD THIS SIDE TO MATCH INCOMING WEATHERBOARD ABOVE WEATHERBOARDS THIS SIDE TO RUN THROUGH TO STUD AND TO BE FIXED FIRST BUILDING WRAP WEATHERBOARDS THIS SIDE TO BE SCRIBED INTO OTHER WEATHERBOARD. PRIME AND SEAL JOINT BETWEEN BOARDS WITH SEALANT FACE NAIL THIS SIDE FIRST -FACE NAIL THIS SIDE TO OUTER STUD 13 BEVEL-BACK TIMBER WEATHERBOARD-TIMBER CAVITY INTERNAL CORNER 1:10 BUILDING WRAP TIMBER CAVITY BATTEN CUT HEAD FLASHING TO CONTINUE PAST WINDOW OPENING SELECTED BEVEL-BACK WEATHERBOARD 32mm LAP AS PER E2/AS1 FLASHING TAPE OVER FLASHING (ALTERNATIVELY USE EXTRA LAYER OF BUILDING WRAP) FLASHING TAPE OVER BUILDING WRAP FITTED AROUND CORNER AS SHOWN LINTEL VERTICAL BATTEN STUDS JAMES HARDIE UPVC VENT STRIP WITH15mm Min COVER HEAD FLASHING WITH 15 Min SLOPE TO 5mm Min GAP BELOW WEATHERBOARD BEVEL-BACK TIMBER WEATHERBOARD-HEAD FLASHING TERMINATION 14 1:10 R 2.2 INSULATION TO VOIDS IN FRAMING TO ALL NEW WALL INTERNAL WALL LINING AS SPECIFIEDO 20mm PARTICLE BOARD TO FLOOR AREAS VERTICAL CAVITY BATTENS WALL UNDERLAY H3.2 SELECTED BEVEL-BACK WEATHERBOARD ON 20mm CAVITY BATTENS OVER BUILDING WRAP OVER 90X45, H1.2, SG8 TIMBER FRAMING.WEATHERBOARD 32mm LAP AS PER E2IAS EXPOL UNDERFLOOR INSULATION POLYSTYRENE PANEL R1.4 TIMBER JOIST 190 X 45@400mm CRS (@400mm IN WET AREAS) FOR ZKPA LOADING PROVIDE TIMBER BLOCK AT MID SPAN POINTS TIMBER BEARER 2/240 X 45 MAX SPAN ZM FOR 2 KPA LOADING PROVIDE TIMBER AT MID SPAN POINTS -H5 TIMBER PILES TO BE 125mm SQ.MIN. TIMBER SLAT WORK FIXED TO PILES 15 DWELLING & PERIMETER WALL DETAIL -20mm PARTICLE BOARD TO FLOOR AREAS X -EXPOL UNDERFLOOR INSULATION POLYSTYRENE PANEL R1.4 TIMBER JOIST 190 X 45400mm CRS (400mm IN WET AREAS -FOR 2KPA LOADING PROVIDE TIMBER BLOCK AT MID SPAN POINTS TIMBER BEARER 2/240 X 45 MAX SPAN 2M FOR 2 KPA LOADING PROVIDE TIMBER AT MID SPAN POINTS HS TIMBER PILES TO BE 125mm SQ.MIN. 16 DWELLING FLOOR DETAIL 1:5 SECTION 6 - FOUNDATION AND SUBFLOOR FRAMING NZS 3604:2011 6 kN joist/bearer connection in direction shown 12 kN learur lo pilu connection or M12 bolt and washers (soa 6,0.5) 90 - 150 12 KN bearer to pile connection or M12 bolt and washers (sed 6.8.5) M12 bot with 50 x 50 x 3 mm washers 100 min Braca anglo 10min 45 max. 2nd brace permited, Wonly 1 broca attached to bottom of pie Max, height above CGL 3 m limber, 1.5 m concrete or masony and min height 3.x distance from lower connection to CGL Footing similar to other pile 300 max. 200 min Lowest point on brace M12 bol with 50 x 50 x 3 mm. washers ( Son SUOSI 6.7.5.2) VASSA Bracing units (along line of bracing) Wind 160 Earthquake 120 CGL CGL Footing see 6.4.5) Braces (500 6.8.3.3) Brace size Max. length 100 x 75 3.0 m 100 x 100 5.0 m NOTE (1). Both piles are braced piles. (2) CGL = Cleared ground level. (3) Ses sedlon 4 for durability requirements Unless otherwise stated, all dimensions are in mm. Figure 6.6 - Braced pile system - Brace connected to pile (see 6.8) CAVITY BATTEN CAVITY CLOSURE WITH 15mm DRIP EDGE TO WEATHERBOARD -WALL UNDERLAY FLAP, LAPPED OVER HEAD FLASHING UPSTAND TILTING FILLET WHERE REQUIRED FOR SUPPORT AIRSEAL OVER BACKING ROD- -5mm GAP FORM HEAD FLASHING WITH 15' SLOPE WITH 20mm STOP-END EXTENDED TO 15mm BEYOND SCRIBER, 10min min COVER TO FLANGE -WALL UNDERLAY METER BOX AIRSEAL OVER BACKING ROD -5mm CLEARANCE SCRIBER WALL UNDERLAY TURNED INTO FRAMING REVEAL, FLEXIBLE FLASHING TAPE TO TRIMMER AND TURN UP 100mm AT ENDS -SEAL AND RIVET 30 x 30mm ANGLE TO METER BOX ALL ROUND PACKING CUT TO SUIT CAVITY BATTEN -H3.2 SELECTED BEVEL-BACK WEATHERBOARD ON 20mm CAVITY BATTENS OVER BUILDING WRAP OVER 90X45, H1.2, SG8 TIMBER FRAMING WEATHERBOARD 32mm LAP AS PER EZ/AS1 Note: Jamb detail similar to silt with angle to give cover to weatherboard with a BEVEL-BACK TIMBER WEATHERBOARD-METERBOX 18 1:5 TIMBER FILLET BACKING TO SUIT, FIXED OVER SEALANT TO SELECTED WEATHERBOARD -FLANGE TO PROTECT SEALANT FROM EXPOSURE TO SUNLIGHT WALL UNDERLAY CAVITY BATTEN - FLEXIBLE FLASHING TAPE ADHERING AROUND PIPE AND ONTO WALL UNDERLAY (100mm LAP TO UNDERLAY AND 25mm TO PIPE) AIR SEAL ALL ROUND SEALANT WITH BACKING ROD PIPE WITH 2" SLOPE PROTECTIVE COWL AIR SEAL ALL ROUND SOLID BACKING AROUND- PIPE PENETRATION CAVITY BATTEN BEVEL-BACK WEATHERBOARD WALL UNDERLAY (20 VENT THROUGH DETAIL 1:5 PLAN VIEW -GB - SILICONE SEALANT RENFORCING MAT EMBEDDED INTO WATERPROOF MEMBRANE CERAMIC TLES OVER WATERPROOF MEMORANG 32:020.55mm VERTICAL FRED GALVANISED STEEL ANGLE 21 WET AREA DETAILS-SHOWER - TILED WALLS AND ACRYLIC BASE-SHOWER WALL DETAIL 1:10 -1B Aqua -SKIRTING SILICONE SEALANT 22 WET AREA DETAILS-SHOWER - TILED WALLS AND ACRYLIC BASE-WALLFLOOR DETAIL 1:10 -GAS Aqueline NPERVOUS SURFACE SILICONE SEALANT -COOK TOP -SEALANT BETWEEN VANITY AND WALL 23 WET AREA DETAILS-KITCHEN AND LAUNDRY-COOK TOP/WALL DETAIL 1:10 10/2011 LUMBERLOK Root Bracing Options 1) ROOF PLANE BRACE URRERLOR ROOF BRACING SPECIFICATION AS PER NZS 3604:2011 Covers roof bracing requirements to resist horizontal loads as set out in NZS 3604:2011 Section 10. Each roof plane brace can be: A hip or valley rafter running continuously from ridge to the top plate in accordance with NZS 3604:2011 Clauses 10.2.1.3.2 or 10.2.1.3.3 OR A pair of tensioned and crossed LUMBERLOK Strip Brace running continuously from ridge to top plate installed as detailed below. A pall of tensioned and crossed LUMBERLOK Sip Brace over top chords/tahes 5 x 30mm x 3.15 diantado 45 sto the rails each and ratar orpurin tine * A definitive guide to the description and installation of Roof Plane Braces and Roof Space Braces. Roof Bracing Requirements 1 x 30mm x 3.15 du nail at crossing (after hensioning Roof Type Light Roof Heavy Roof 5x3mm x 3.15 da. noile ench and When putin dapte above tross chord la son or los Stronca can be mad cver top of pufins, Fie with 1 x 30mm x 3.15 da nail at the pufin dosest to the rates crossing AUCKLAND COUNCIL AP. ES One roof brace per 50m'of roof area (see rule 8 for minimum requirements). One roof brace per 25m'of roof area (see rule 8 for minimum requirements) II) ROOF SPACE BRACE 10) Not directly under the ridge - Isss than 2m long. 4 x Sommal 01 DEC 2016 APPROVED BUILDING CONSENT PLANS 1A) Less than 2m long. each and TA 10.45 urt in. bon chords 2x pohod & na TA each and 7045 Red Floset as there botom w with 3x m 2 raia wached a poco 3x rats enth and Rooi Bracing - Rules & Definitions 1. The bracing described in this brochure covers both framed roofs and fully trussed roots. 2. Roof planes less than 6m (e.g.domers & porches) do not require bracing. 3. Roof braces can consist of either i) Roof Plane Brace or ii) Roof Space Brace or combination of the two. 4. Roof braces are not required on roofs where sarking is installed as per NZS 3604:2011 Clause 10.4.4 or where a coiling diaphragm is installed and is attached to the rafters. 5. Roof area is the actual plan area of the root and includes overhangs. 6. A hip or valley rafter running continuously from ridge to top plate can be classed as one roof plane brace. 7. A pair of crossed LUMBERLOK Strip Brace (preferred for ease of installation) can be classed as one root plane brace and shall be installed as detailed in this brochure. 8. There must be at least one roof plane brace in each roof plane. Each ridge line shall have a minimum of two roof braces. 9. Every design effort should be made to distribute the roof braces as evenly as possible over the entire roof area and run alternately in opposite directions. + 0x45 Respon 0x45 Materace pertelor wie wema wa per within 28 di brengt wat preto 30 brucing element pent to be the ang D) Nora then 2m Sorg (Max. 4.6m). (D) Net directly under the ridge - more than 2m lang. Trum Fiecare 3x #xmas 3x as each end 4 ton par maluchard side and each end side and each and Blocking Daten we 30x45 Root 70 Rumelad trombers 2015 med orcebrece para el town of 1. Boronder amino wwal hoon her with who de paine 2 shers mis teeth 2x was perched raibe herd 31 OCT 2015 09 B AUCKLAND COUNC". 2/30 x 45 Rool pebre webcu members per or with a romal wel som 1. Ons. Fi with wawwal partida trading demont 2x Sonnteach side nching *Het required when calling diaphragn complying with Class 185 ZS 2011 d. man 0 1 2 576 19 NORTHERN WAT MiTek - MiTek New Zealand Limited AUCKLAND PC. CRISTOUPEN PORT, 02N 116 SSINS from GANO-NAIL LUMBERLOK BOWMAC Ger 14 MiTek CM AR DRAWN KF DATE 30/10/16 23 ASSEMBLY DETAILS-CEILING PLANE BRACING NTS CHKO SCALE NTS KF BUILDING CONSENT DRAWING TITLE CEILING PLANE BRACE 09/2011 LUMBERLOK STUD TO TOP PLATE FIXING SCHEDULE ALTERNATIVE TO TABLE 8.18 NZS 3604:2011 the NOTE: All fixings are designed to resist vertical loads only. Dead loads include the foot weight and standard ceiling weight of 0.20 Pa. These fixings assume the correct choice of raftertruss to top plato connections have been made. Gabio and was to plata/stud connections where the adjacent raternas s located within 1200mm of gable end wall with a maximum verge overhang of 750mg, requires foing type A as shown below. Airfixings assume top plate thickness of 45mm maximum. Wat framing arrangements under girder Brusses are not covered in this schedule. All timber selections are as per NZS 3004:2011. LOADED DIMENSION DEFINITION FIXING OPTIONS FIXING TYPEA) 2 Orm 23.15 dia. plain sinet wie nalediven eftcaly into the 0.7 kN calle Extemal wat Standards Extemat wall Ineinaty supported use T FIXING TYPE B CHOOSE ANY OF THE 2 OPTIONS BELOW 4.7 KN Extort was Ratier rool EN Extmal wat Jack FYTORA WALL LONDED DISION 2x90mm x 3.15 ajtain steel 2 x 30mm3.15 di, plin steel wire mais diven veilically inte saudenal dilen veiciny into stud. niemal wall Iniemaly ponedIn VITAL LOADED DISOR TOTAL SPAM WULFPUTEROU ALL D DATHmaran) WALLA Plus Plus LUMBERLOK 2 x LUMBERLOK EN Sud Anchor CPCAO (CPH Recommended for internal wall options to avoid iringe 2x90mm x 3.15 da plains wie nails driven vertically nieshd. WALLS Mutilaria wale FIXING SELECTION CHART (Suitable for was supporting rool members 600,000 or 1200mm) Wind Zones L, M, N,V, EH, as per Nas31062011 Land Dimension Light cool Heavy Real Sud Centres Wind Zone Wind Zone metom m MH.VELMH.ME 30 23 15 1.0 20_L 20 50 2016 80 45 SOAL 10 125 A 10 90 A. 2500 2 11653 35 B 120 90 80 Plus LUMBERLOK Stud Strap Note: To clap the number of the Rings required, dvidene wall length by hand cenies, add to his ligure and local this number of folg as every as possible along the wait long. This gimtindudes the stan and and studs in each wall length | MiTek AH 24 ASSEMBLY DETAILS-LUMBERLOK-STUD & TOP PLATE CONNECTION NTS Panel Hold-down Details 100mm maximum Concrete Floor - Internal / External Wall Bottom plate is fixed using an M12 galvanised bolt set not less than 75mm into concrete and projecting sufficiently to allow for a 3mm washer and fully-threaded nut above the timber. Alternatively a proprietary fixing with equivalent capacity may be used. M12 galvanised bolt and 50 x 50 x 3mm square galvanised washer Six 30 x 2.5mm galvanised flat head nails to each side of stud 400 x 25 x 0.9mm galvanised strap (strap passes underneath bottom plate) Three 30 x 2.5mm galvanised flat head nails to each side of bottom plate Timber Floor - Internal Wall Bottom plate is fixed using a 12mm diameter minimum 150mm long galvanised coach screws. Six 30 x 2.5mm galvanised flat head nails to each side of stud 400 x 25 x 0.9mm galvanised strap (strap passes underneath bottom plate) 100mm maximum 12mm x 150mm galvanised coach screw and 50 x 50 x 3mm square galvanised washer Three 30 x 2.5mm galvanised flat head nails to each side of bottom plate Timber Floor - External Wall Alternatives Bottom plate is fixed using a 12mm diameter minimum 150mm long galvanised coach screw with 50 x 50 x 3mm square galvanised washer. Alternatively use the double strap detail showsi on the right Six 30 x 2.5mm galvanised flat head nails to each side of stud wa 3002 0.9 galvanised straps Blockport Jg fixed with threa, 100 3.5m rails to stud to accomtradale dooble strup 100mm maximum -400 x 25 x 0.9mm galvanised strap (strap passes underneath bottom plate) Three 30 x 2.5mm galvanised flat head nails to each side of bottom plate Sl30 x 25mm Option 1 Option 2 galvanised ahead walls to each stud and yokt Notes: Hold down straps may require additional thickness and/or corrosion protection. Consult NZS3604:2011 for requirements. To maintain a flush surface for the wall linings, it is recommended that hold down straps are checked into the framing. 25 ASSEMBLY DETAILS-BOTTOM PLATE FIX FOR BRACING NTS IB 610 FIRST FLOOR 72.92 --- GROUND FLOOR 70.50 W1.03 SOOH 1800W 1600SILL W1.02: 900 x 600W 1200SILL DOOR WINDOW SCHEDULE- NORTH ELEVATION1 1: 100 DID FIRST FLOOR 72.92 GROUND FLOOR 70.50 W1.07: 1200H x 900W 900SILL 01.02: 2100H x 1800W DOOR/WINDOW SCHEDULE-SOUTH ELEVATION1 1:100 2410 1820 FIRST FLOOR 72.92 WNA mo GROUND FLOOR 70.50 W1.06 1200H x 2400W SOOSILL W1.05 1200H X 1800W 900SILL W1.04 1200 x 1800W 900SILL AU DOOR/WINDOW SCHEDULE-WEST ELEVATION1 1:100 BUI 1360 610 FIRST FLOOR 72.92 003 GROUND FLOOR 70.50 W1.01: 900H X 600W 12005ILL. D1.01: 2100H x 1350W W1.08 900H x 600W 1200SILL DOOR/WINDOW SCHEDULE-EAST ELEVATION 1: 100Step by Step Solution

There are 3 Steps involved in it

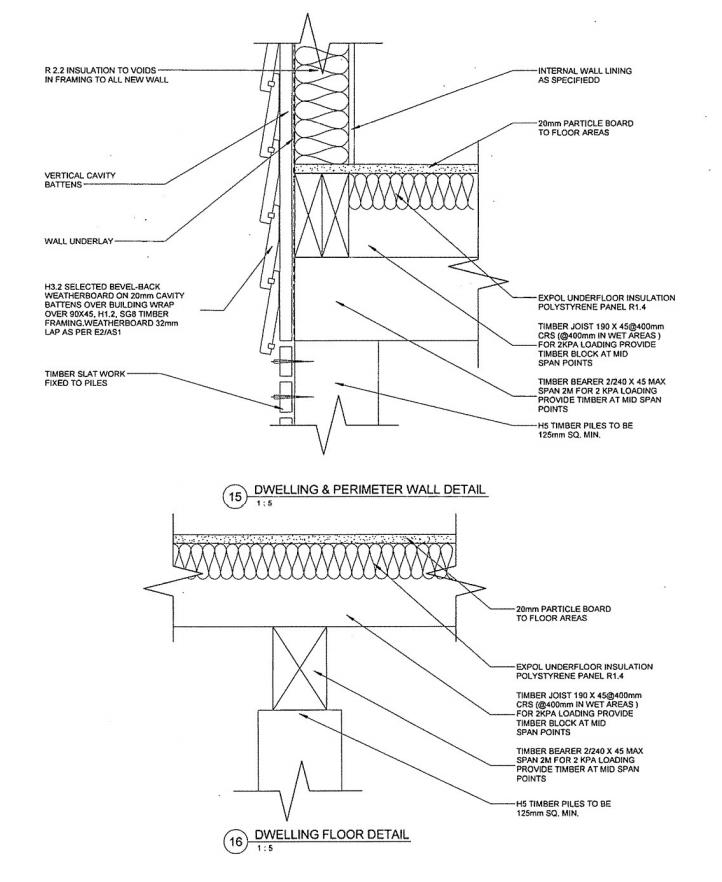

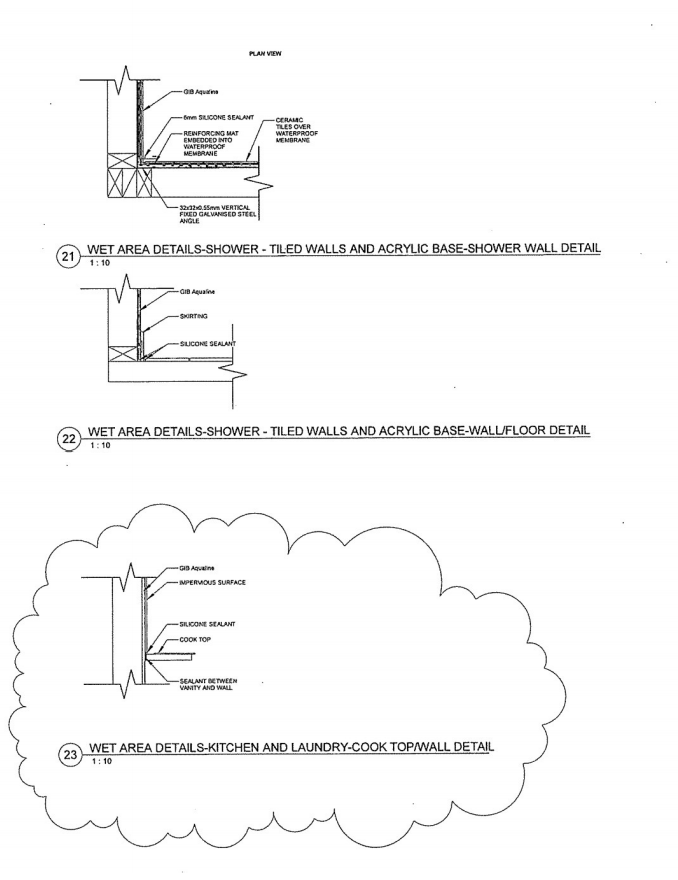

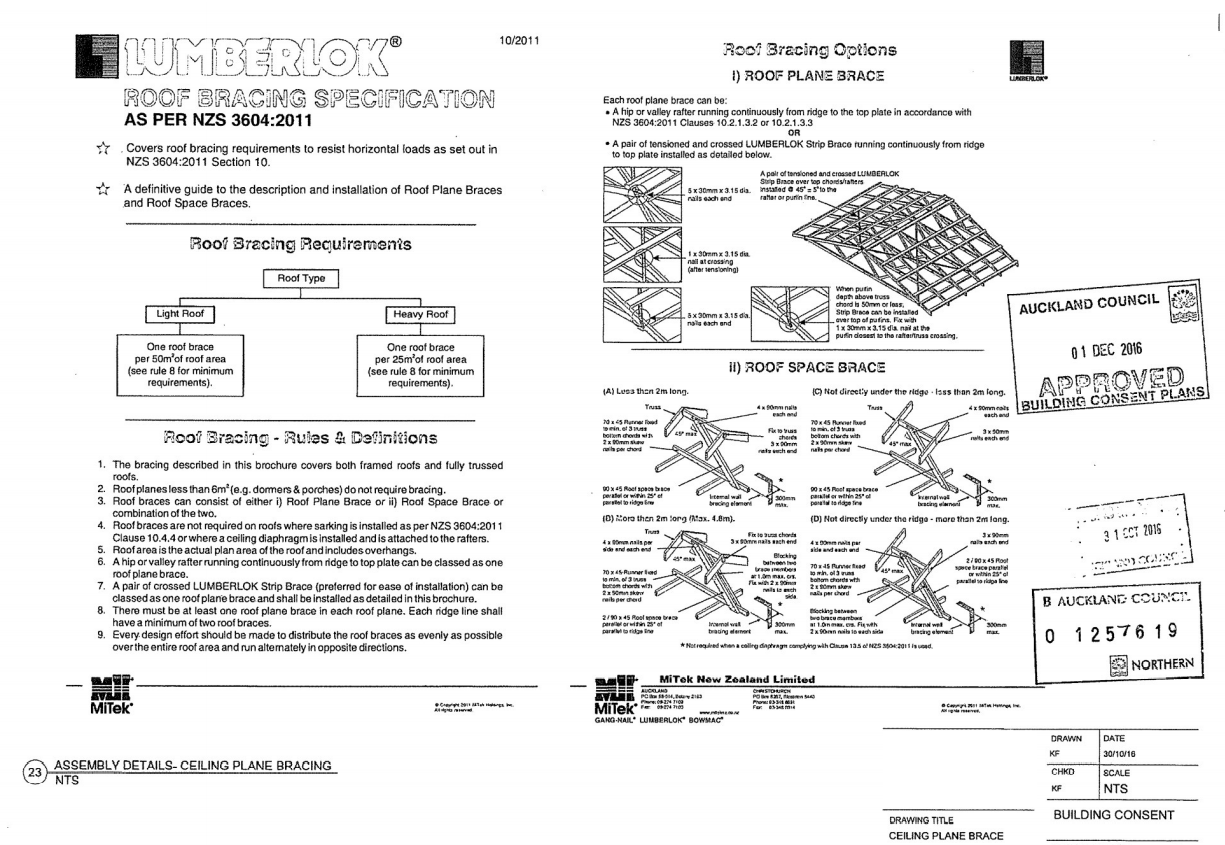

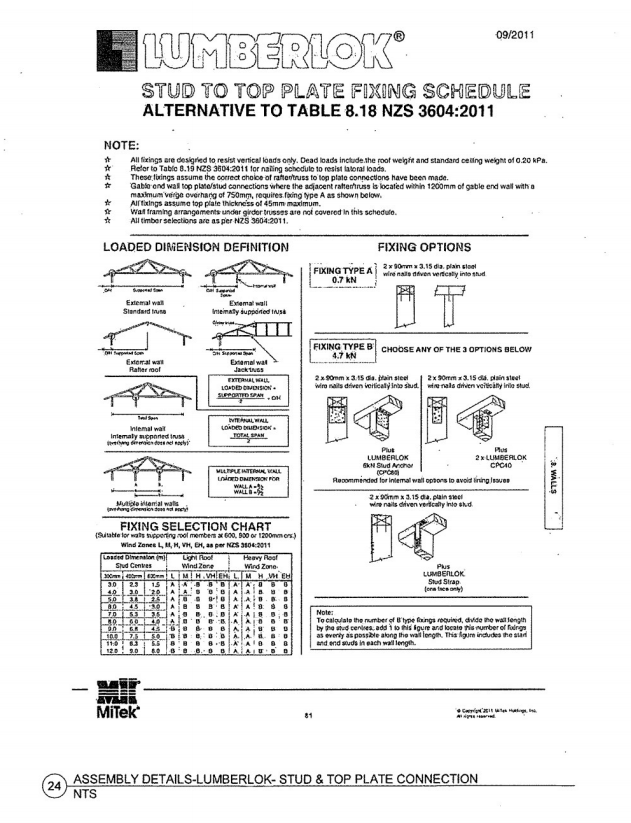

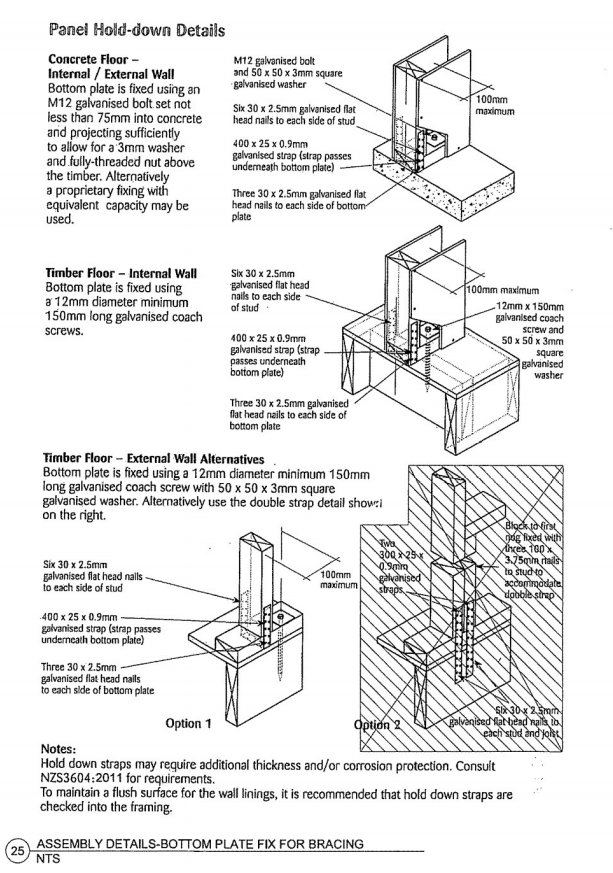

Get step-by-step solutions from verified subject matter experts