Question: Assignment 16 (process Map) A driver enters a licensing bureau to have her licence renewed. She spends on an average 45 minutes in line, two

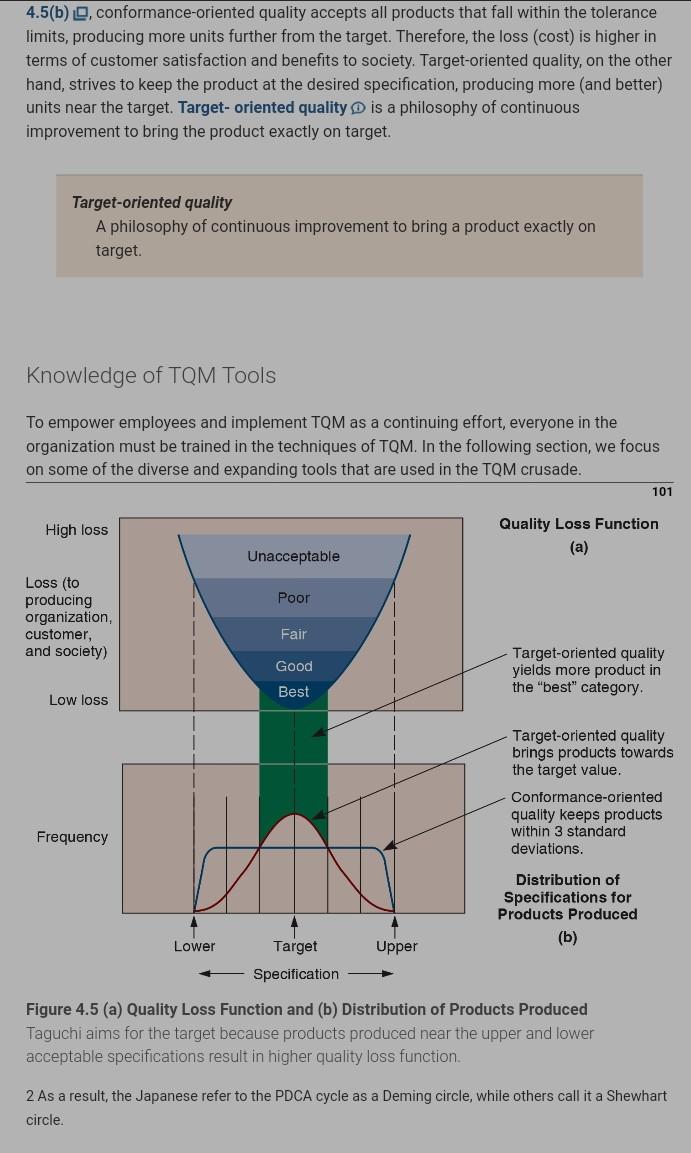

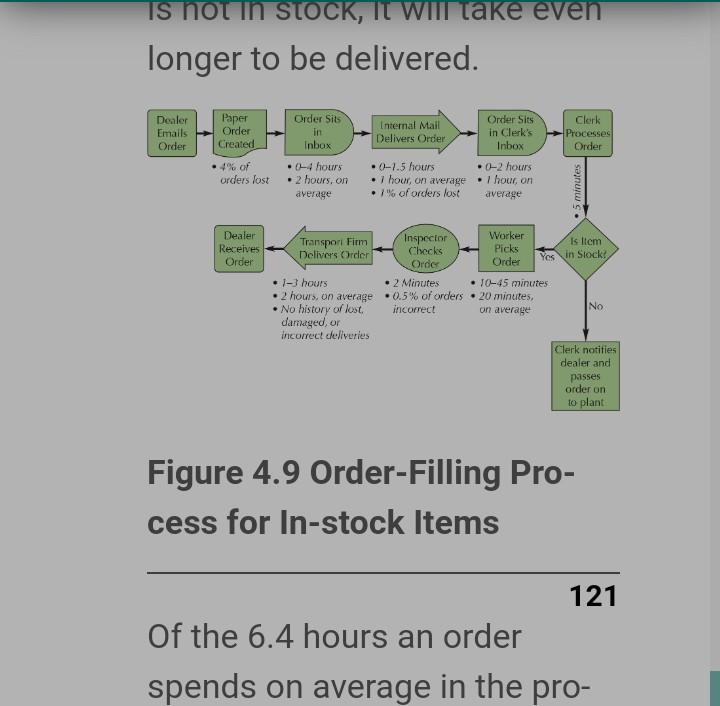

Assignment 16 (process Map) A driver enters a licensing bureau to have her licence renewed. She spends on an average 45 minutes in line, two minutes to have her eyes tested, 3 minutes to have her photograph taken, and 1 minute to enter her signature. Draw the process map using symbols shown on page 120 and also those discussed in class (start/finish, activity, delay, inspection, move, document) Calculate the cycle time in minutes What is value added time in this case? 4.5(b) , conformance-oriented quality accepts all products that fall within the tolerance limits, producing more units further from the target. Therefore, the loss (cost) is higher in terms of customer satisfaction and benefits to society. Target-oriented quality, on the other hand, strives to keep the product at the desired specification, producing more (and better) units near the target. Target-oriented quality is a philosophy of continuous improvement to bring the product exactly on target. Target-oriented quality A philosophy of continuous improvement to bring a product exactly on target. Knowledge of TQM Tools To empower employees and implement TQM as a continuing effort, everyone in the organization must be trained in the techniques of TQM. In the following section, we focus on some of the diverse and expanding tools that are used in the TQM crusade. 101 High loss Quality Loss Function (a) Unacceptable Poor Loss (to producing organization, customer, and society) Fair Good Best Target-oriented quality yields more product in the "best" category. Low loss Target-oriented quality brings products towards the target value. Conformance-oriented quality keeps products within 3 standard deviations. Frequency Distribution of Specifications for Products Produced (b) Lower Target Upper Specification Figure 4.5 (a) Quality Loss Function and (b) Distribution of Products Produced Taguchi aims for the target because products produced near the upper and lower acceptable specifications result in higher quality loss function. 2 As a result, the Japanese refer to the PDCA cycle as a Deming circle, while others call it a Shewhart circle The last measure of process performance we will discuss is cycle time. Cycle time (also called throughput time) is the total elapsed time needed to complete a business process. Many authors have noted that cycle time is a highly useful measure of process performance. For one thing, in order to reduce cycle times, organizations and supply chains typically must perform well on other dimensions, such as quality, delivery, productivity, and efficiency. Cycle time The total elapsed time needed to complete a business process. Also called throughput time. Consider the order-filling process in Figure 4.9. In this case, cycle time is the time that elapses from when the dealer emails the order until she receives the product. Notice how the process suffers from delays due to waiting, lost orders, and incorrect orders. Therefore, in order to reduce cycle time, the San Diego DC must address these other problems as well. Notice, too, that reducing cycle times does not mean "fast and sloppy." The process cannot be considered "complete" until the dealer receives a correctly filled order. A second advantage of cycle time is that it is a straightforward measure. In comparison to cost data, quality levels, or productivity measures-all of which may be calculated and interpreted differently by various process participants--the time it takes to complete a business process is unambiguous. In addition to measuring cycle time in absolute terms, it is often useful to look at the percent value-added time, which is simply the percentage of total cycle time that is spent on activities that actually provide value:Percent value-added time (4.1) Percent value-added time = 100% (value-added time)/(total cycle time) Percent value-added time A measure of process performance; the percentage of total cycle time that is spent on activities that actually provide value. For example, what is the percent value-added time for the typical "quick change" oil center? Even though the customer may spend an hour in the process, it usually takes only about 10 minutes to actually perform the work. According to Equation (4.3), then: Percent value-added time = 100% (10 minutes)/(60 minutes) = 16.7% Of course, cycle time is not a perfect measure. Our discussion in Chapter 2 of trade-offs between performance measures applies here as well. It might not be cost-effective, for example, to drive down cycle times at the drivers' license bureau by quadrupling the want to the Theated Onities that IS nou in SLOCK, It will take even longer to be delivered. Dealer Emails Order Paper Order Created 4% of orders lost Order Sits in Inbox Internal Mail Delivers Order Clerk Processes Order Order Sits in Clerk's Inbox 0-2 hours 1 hour, on average . 0-4 hours 2 hours, on average .0-1.5 hours 1 hour, on average /% of orders lost 5 minutes Dealer Receives Order Inspector Worker Transpori Firm Is Item Checks Picks Delivers Order Order Order Yes in Stock: 1-3 hours 2 Minutes 10-45 minutes 2 hours on average .0.5% of orders. 20 minutes, No history of lost incorrect on average No damaged, or incorrect deliveries Clerk notities dealer and passes order on to plant Figure 4.9 Order-Filling Pro- cess for In-stock Items 121 Of the 6.4 hours an order spends on average in the pro

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock